Artificial digging repair novel construction method for collapse ultra-deep shaft

A shaft and artificial technology, applied in shaft equipment, shaft lining, mining equipment, etc., can solve problems such as economic losses, and achieve the effect of speeding up construction progress, ensuring construction quality, and ensuring construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

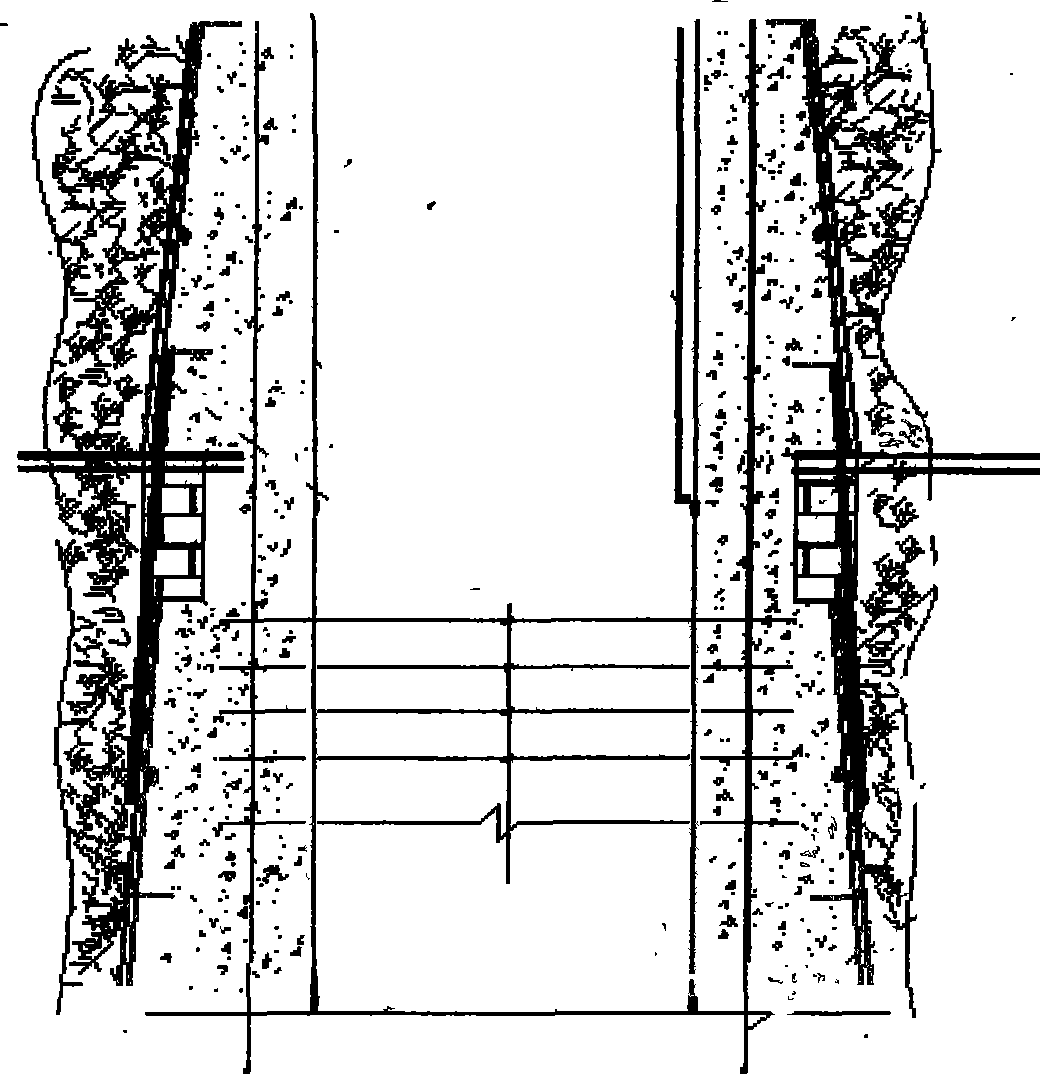

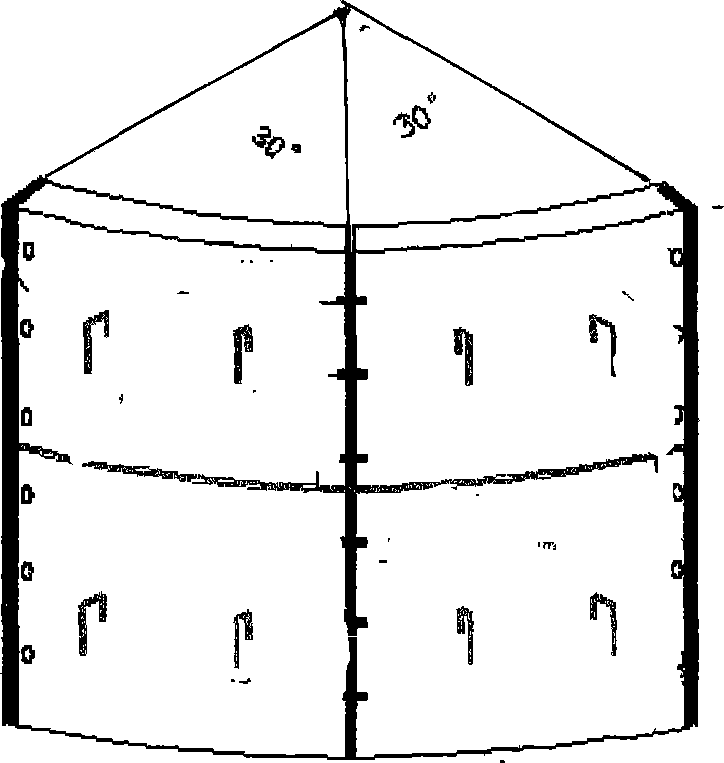

[0019] according to figure 1 , figure 2 As shown, a new artificial excavation repair method for collapsed ultra-deep shafts, the steps are as follows:

[0020] (1) According to the designed diameter, excavate a deep pit of 1.0-1.4m;

[0021] (2) Install the steel formwork, the formwork is spliced with bolts, the angle steel part is fully welded on one side, the outside of the steel formwork is provided with hanging ribs, and the second mold is excavated after pouring C30 wall protection concrete;

[0022] (3) After the excavation size of the second mold meets the requirements, and before pouring the retaining wall concrete, at least 2 steel bars are welded on the inner side of each steel formwork side wall of the previous mold, the length of which is L=1150-1500mm, and the other end extends into the The outer side of the steel formwork of the second formwork is to be poured at the retaining wall, and the C30 retaining wall concrete is poured to the top of the steel formwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com