Boiler flue

A boiler flue and flue technology, which is applied in hot water boilers, high-efficiency and energy-saving boiling water fields, can solve problems such as difficult production, installation and maintenance, and occupation of effective water-holding space of the furnace, and achieves compact structure, simple manufacturing process, and high thermal efficiency. Start fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

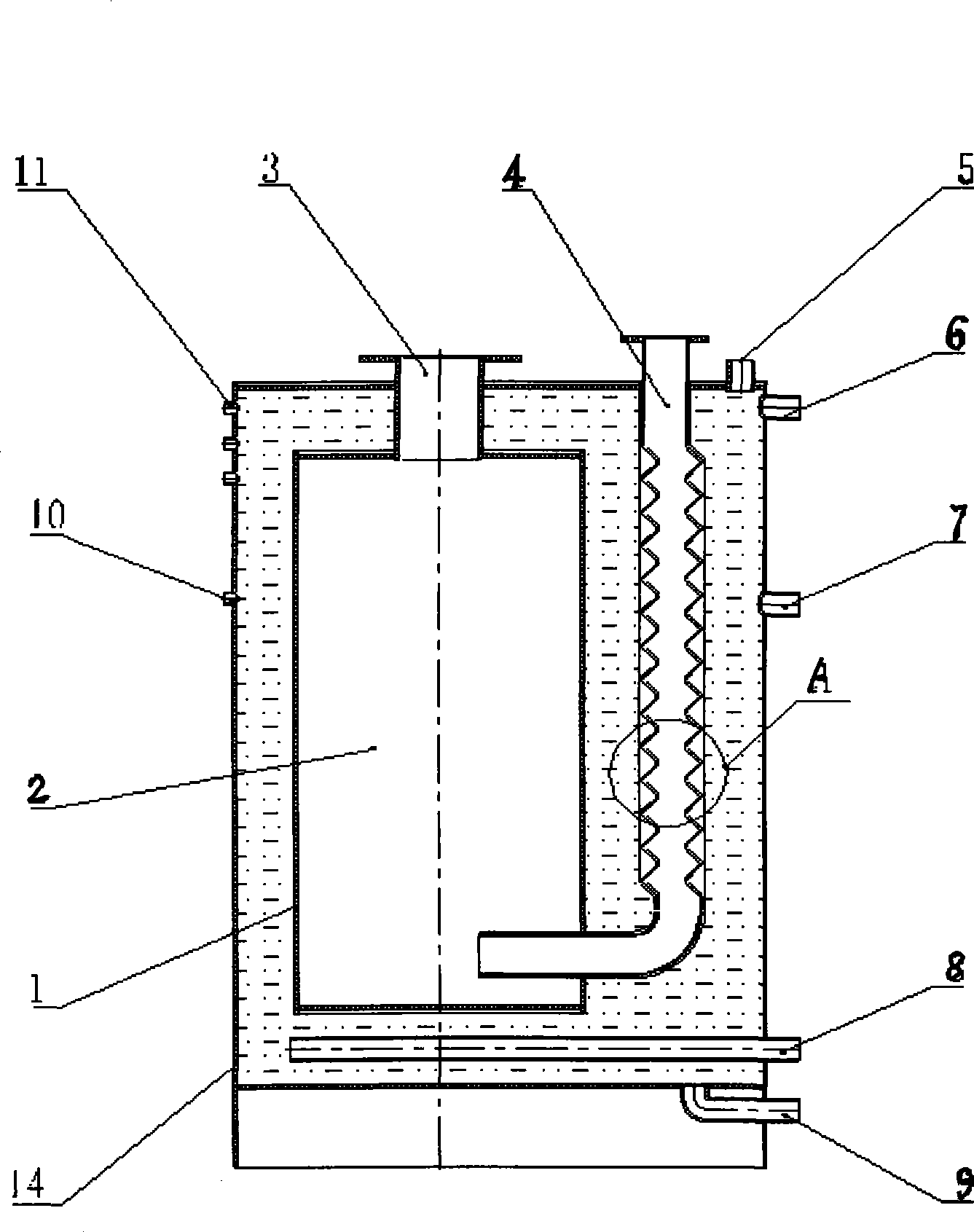

[0022] Such as figure 1 with figure 2 , the structure of the present invention is as follows: a kind of normal pressure boiler flue, relates to the furnace 1 that is surrounded by the pot shell 14, is located in the furnace 2 with the fire door 3 in the furnace 1, passes through the furnace 1 The flue 4 of the furnace 2 is characterized in that the inner and outer surfaces of a section of the flue 4 in the furnace 1 are at least partly in a shape of alternating convex and concave. The wall of the furnace is also provided with an opening 5 between the furnace and the atmosphere, a hot water outlet 6, a boiling water outlet 7, a water inlet 8, a sewage outlet 9, a temperature control device 10, and a water level control device 11.

[0023] Such as Figure 4 The cross-sectional shape of a section of the flue 4 located in the furnace 1 is generally circular, but there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com