Electromagnetical ultrasonic thickness-measuring method

An electromagnetic ultrasonic and permanent magnet technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems such as the inability of piezoelectric ultrasonic thickness gauges to work, the inability to detect rough surface materials, and the limitation of application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

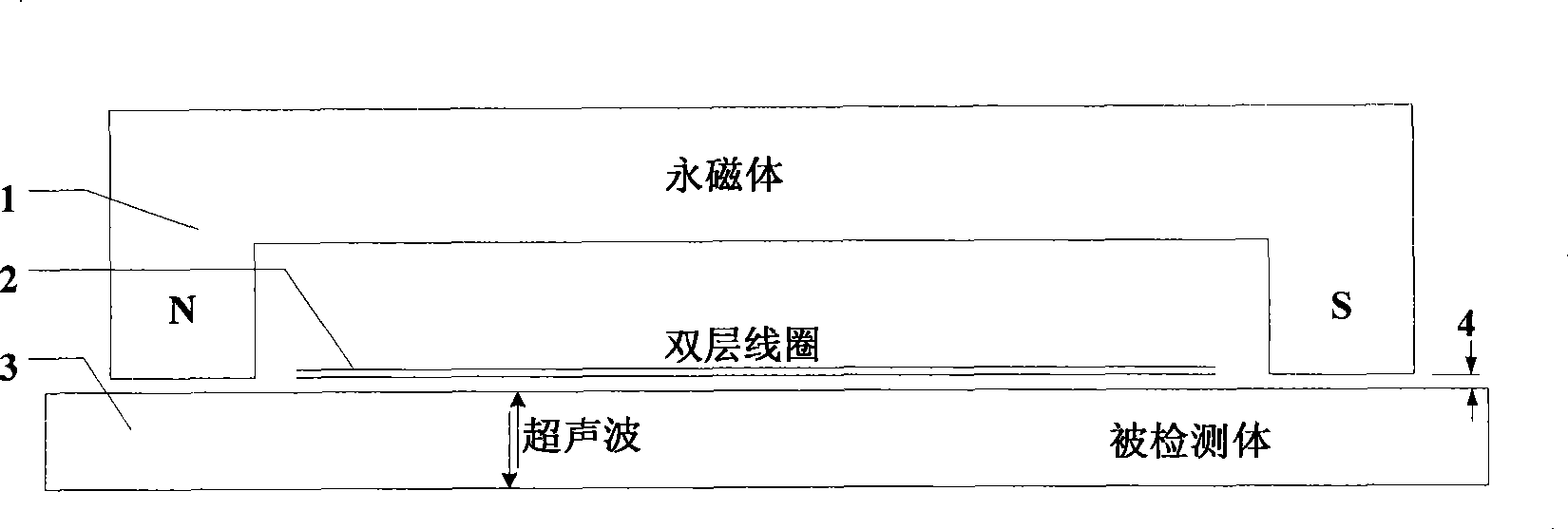

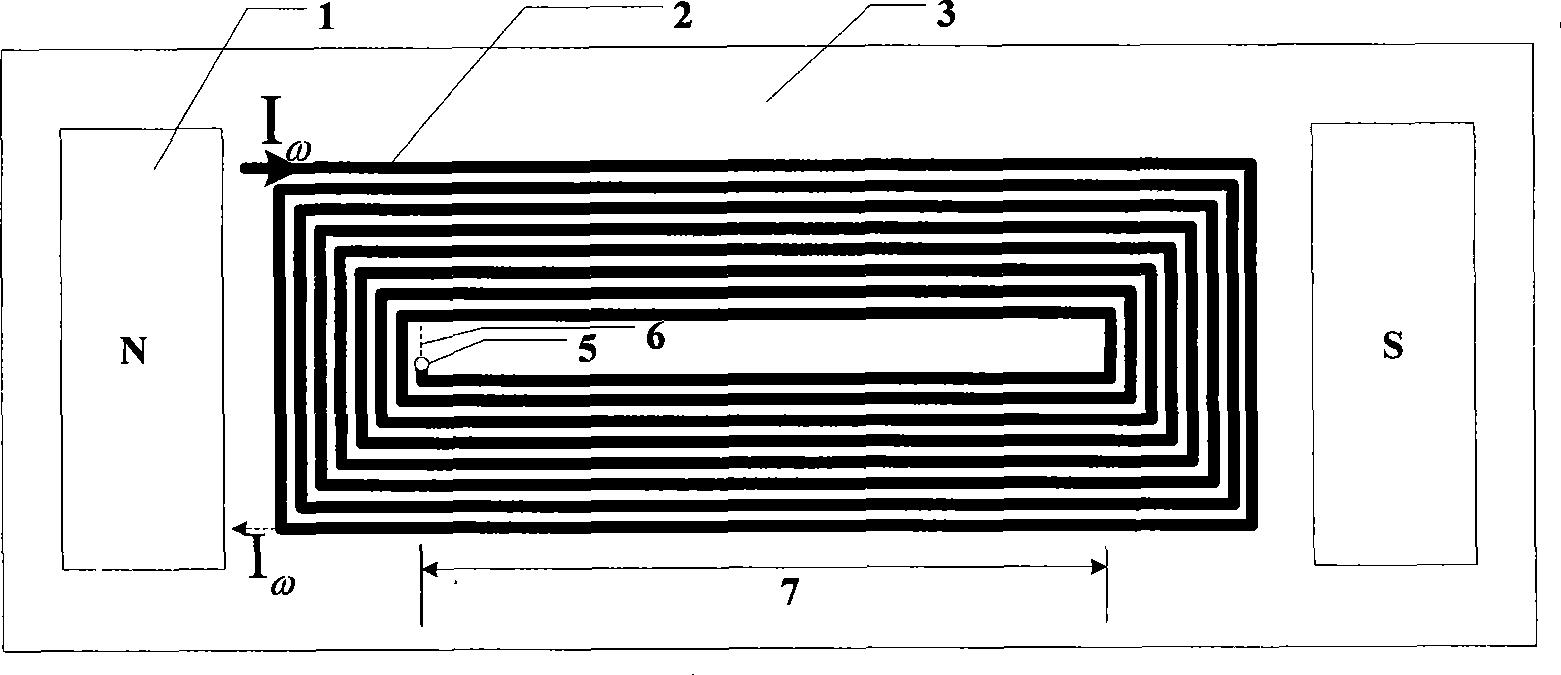

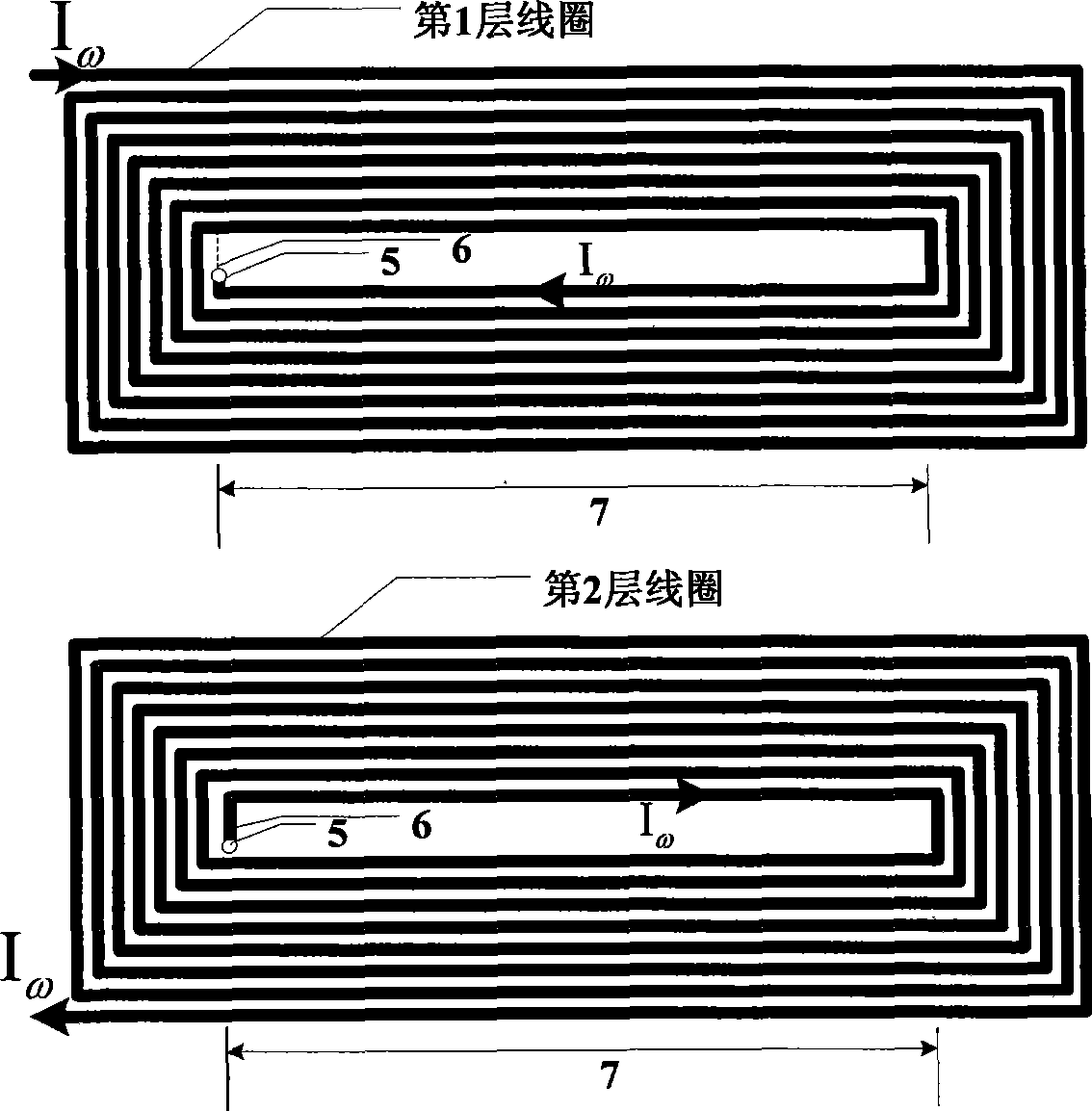

[0018] In the present invention, the electromagnetic ultrasonic transducer is designed based on the principle of magnetostriction, the magnet is a U-shaped NdFeB permanent magnet, and the coil is a "back" double-layer coil. The U-shaped permanent magnet is 40mm-70mm long, 30mm-50mm wide, and 10mm-20mm high; the coil is 30mm-60mm long, 20mm-40mm wide, and the total thickness is 0.3mm-1.5mm. The U-shaped permanent magnet is placed on the object to be tested, and the lift-off height is 0.5mm-1mm, and the magnetic induction intensity of the bias magnetic field generated in the object to be tested is 0.5T-1T. In order to improve the conversion efficiency of the electromagnetic ultrasonic transducer, a double-layer coil is designed to excite and receive ultrasonic waves. The horizontal positions of the upper and lower coils are the same, so that the current direction of the wire at the same position of the first layer and the second layer coil is the same. Such as image 3 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com