Refrigerating machine oil composition

A technology for refrigerating machine oil and composition, which can be used in lubricating compositions, refrigerators, compressors, etc., and can solve problems such as reduced sealing or lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

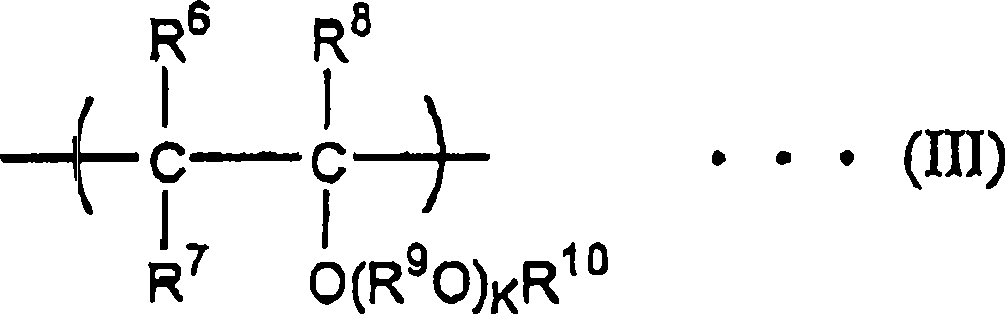

Method used

Image

Examples

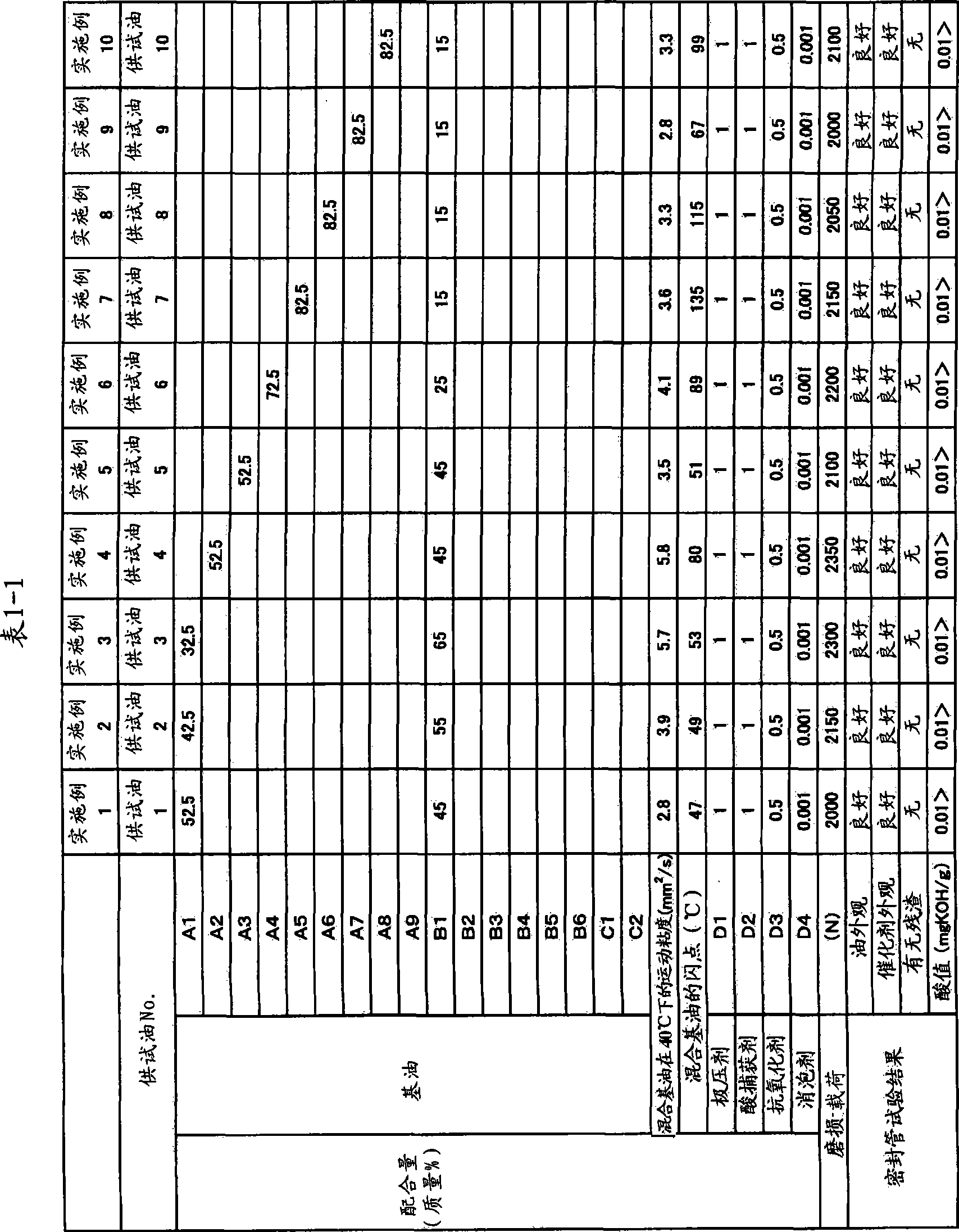

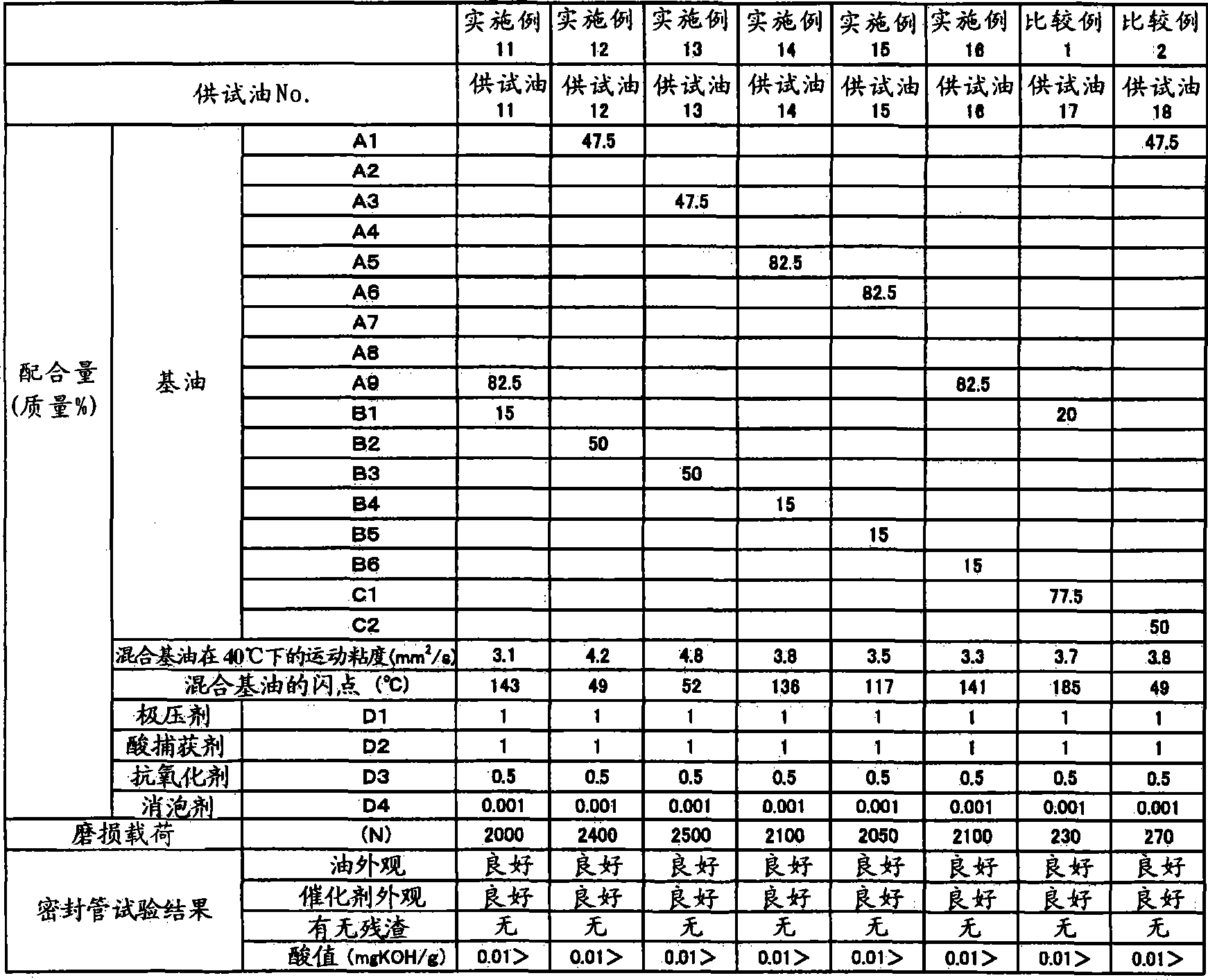

Embodiment 1-16 and comparative example 1、2

[0154] The refrigerating machine oil compositions with the compositions shown in Table 1 were prepared, and the wear load thereof was measured, and the sealed tube test was carried out simultaneously. The results are shown in Table 1.

[0155] [Table 1]

[0156]

[0157] [Table 2]

[0158] Table 1-2

[0159]

[0160] [Note]

[0161] A1: naphthenic mineral oil, kinematic viscosity at 40°C = 0.98mm 2 / s, S minutes=25 mass ppm, flash point=45°C, average molecular weight=120, molecular weight distribution=1.1

[0162] A2: Paraffinic mineral oil, kinematic viscosity at 40°C = 2.24mm 2 / s, S minutes = 1 mass ppm or less, flash point = 78°C, average molecular weight = 170, molecular weight distribution = 1.1

[0163] A3:C 4 Oligomer of olefin (main component isobutylene), kinematic viscosity at 40°C = 1.25mm 2 / s, flash point=49°C, average molecular weight=142, molecular weight distribution=1.2

[0164] A4: C 4 Oligomers of olefins (main component isobutylene), kinemati...

Embodiment 17、18 and comparative example 3、4

[0184] The wear load of the test oils shown in Table 2 was measured, and at the same time, the amount of oil deposition was measured. The results are shown in Table 2.

[0185] [table 3]

[0186] Table 2

[0187]

[0188] [Note]

[0189] C3: naphthenic mineral oil, kinematic viscosity at 40°C = 4.2mm 2 / s, S minutes=20 mass ppm, flash point=145°C, average molecular weight=310, molecular weight distribution=1.2

[0190] C4: dimer of 1-decene, kinematic viscosity at 40°C = 4.9mm 2 / s, flash point=172°C, average molecular weight=282, molecular weight distribution=1

[0191] Others are the same as Table 1.

[0192] As can be seen from Table 2, the refrigerating machine oil compositions of Examples 17 and 18 containing mixed base oils of the present invention had higher wear loads and higher oil adhesions than Comparative Examples 3 and 4 containing a single base oil.

Embodiment 19-22 and

[0193] Embodiment 19-22 and reference example 1

[0194] With regard to the test oils shown in Table 3, a sealing performance comparison test was performed using the sliding part materials shown in Table 3. The results are shown in Table 3.

[0195] [Table 4]

[0196] table 3

[0197] Example 19 Example 20 Example 21 Example 22 Reference example 1 Test oil No. Test oil 12 Test oil 13 Test oil 13 Test oil 13 Test oil 13 sliding material E1 E2 E3 E4 E5 Leakage

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by mass | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| partial pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com