Net clothing cleaning machine

A washing machine and net clothes technology, applied in cleaning methods and appliances, cleaning methods using tools, climate change adaptation, etc., can solve the problems of large cleaning resistance, inconvenient operation, etc., to reduce labor intensity, save labor and improve efficiency. The effect of cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

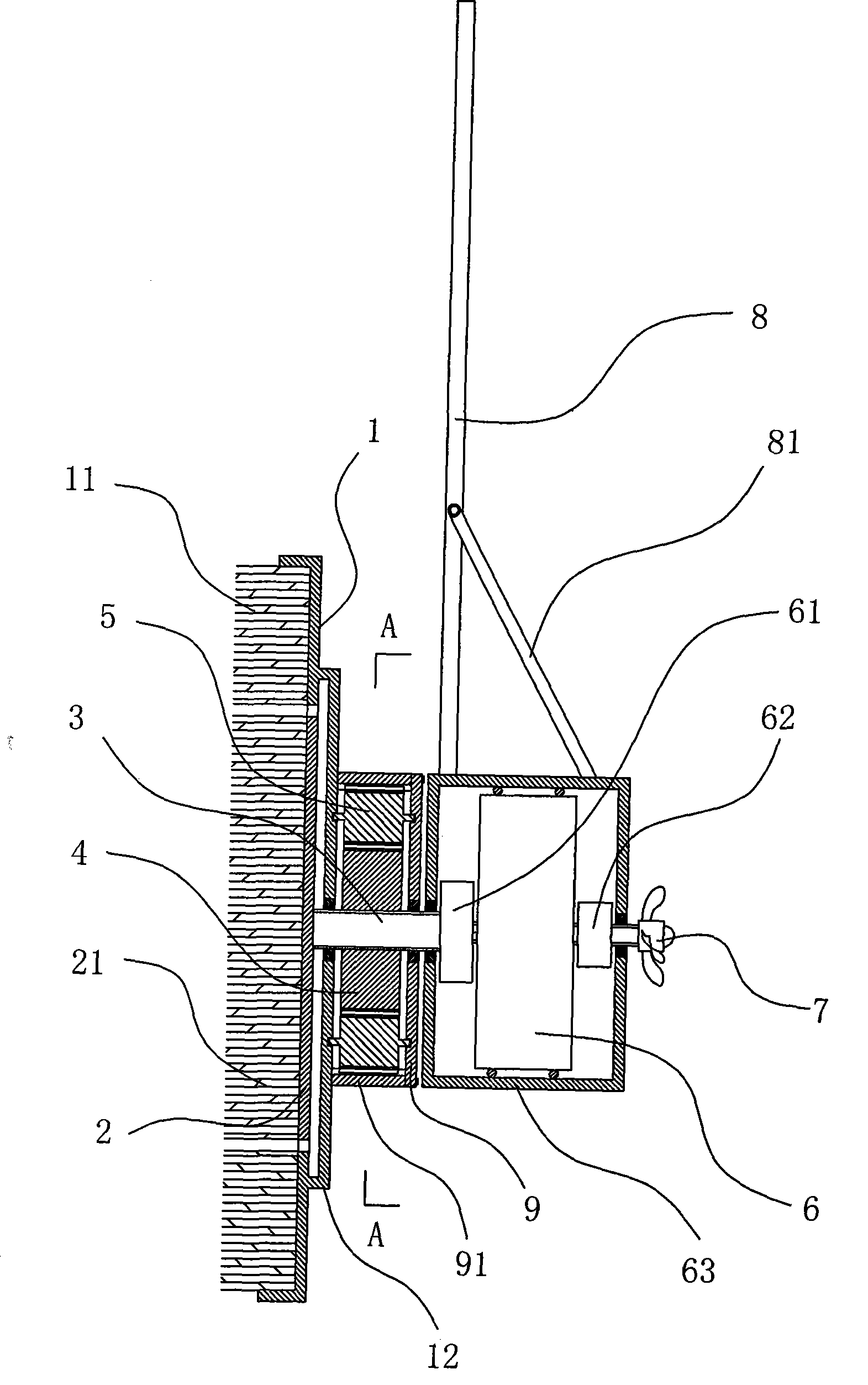

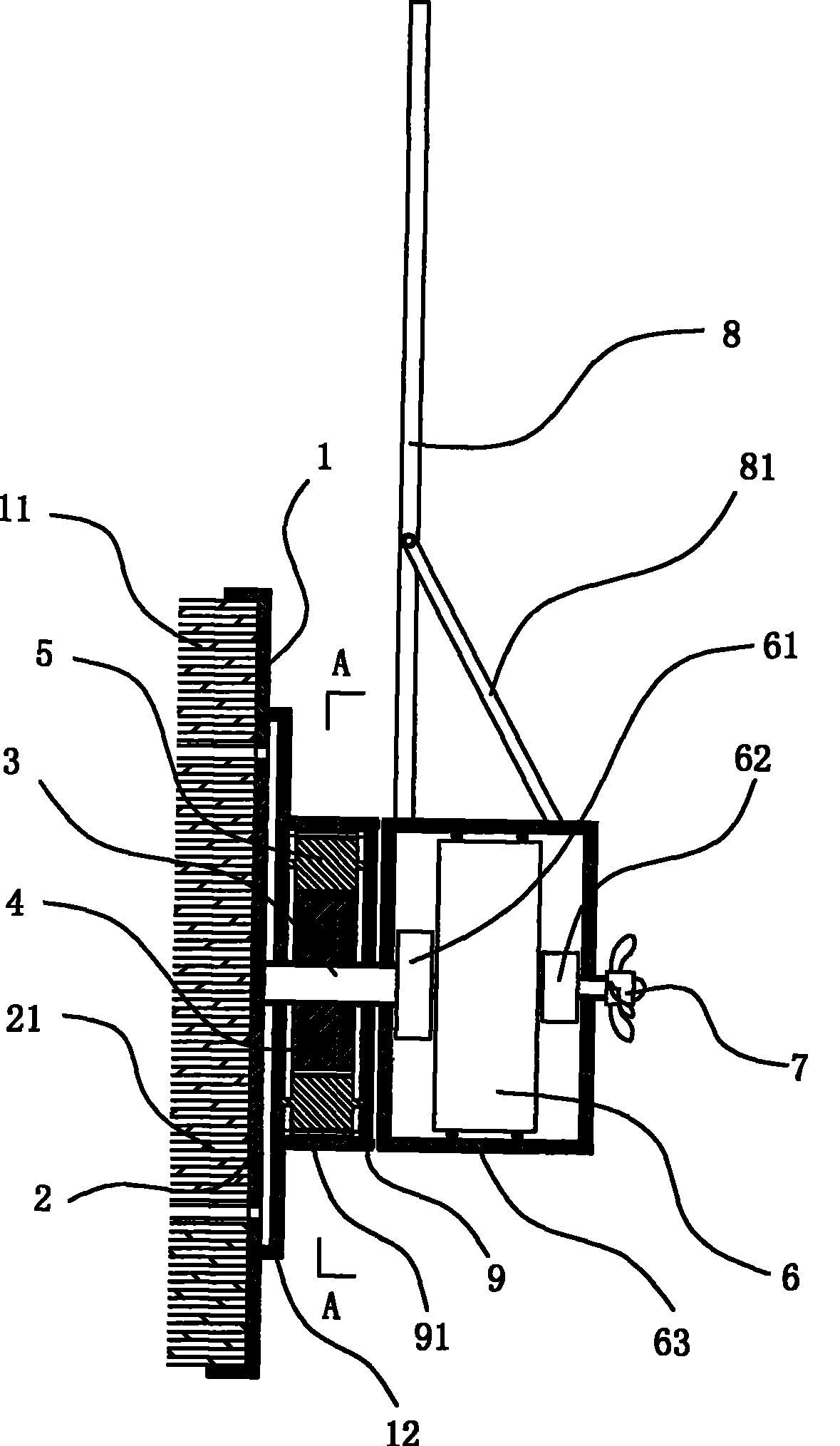

[0021] Example: refer to figure 1 To Fig. 3, a kind of net clothing cleaning machine comprises the annular outer brush 1 that has outer bristle 11, wherein: the inner brush 2 that has inner bristle 21 is arranged on the inner edge of outer brush 1; Outer brush 1 and The inner brush 2 is connected to one end of the power mechanism through the reversing transmission mechanism, so that the outer brush 1 and the inner brush 2 can rotate in different directions; the other end of the power mechanism is connected to the propeller 7, and the axial thrust generated by it is greater than or equal to the outer brush. The thrust generated by the rotation of brush 1 and inner brush 2.

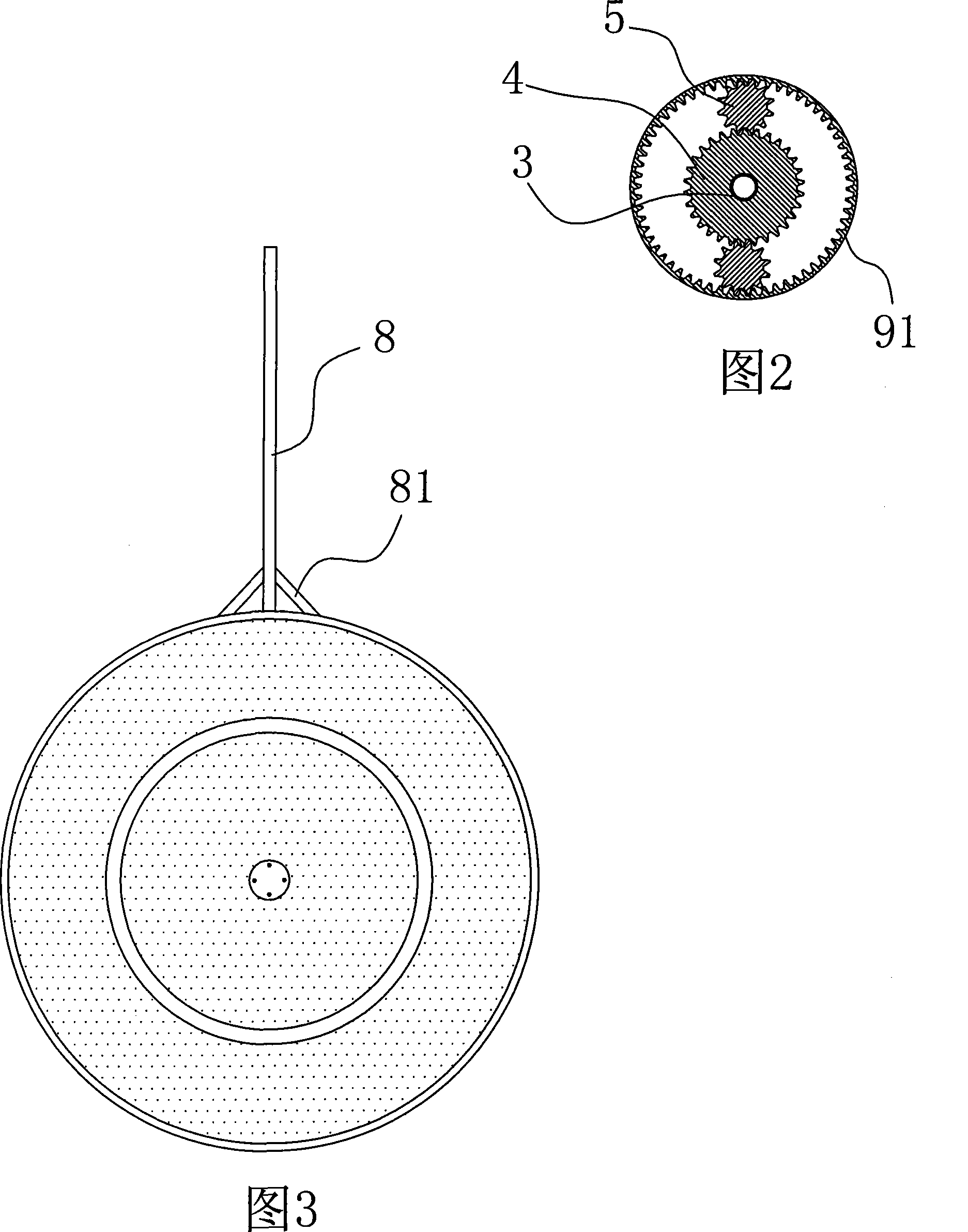

[0022] The transmission mechanism includes the inner brush shaft 3, the inner brush gear 4, the outer brush ring gear 91, the gear cover 9 and two conversion gears 5; the gear cover 9 is connected with one end of the outer brush ring gear 91; the outer brush ring gear 91 Convex teeth are formed on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com