Tool change device with a direct drive reciprocating and pivoting actuator

一种换刀装置、驱动装置的技术,应用在工具更换装置、机电装置、喂食装置等方向,能够解决高磨损、低可用性等问题,达到高机械刚性和驱动刚性、提高动态特性和动态抗干扰性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

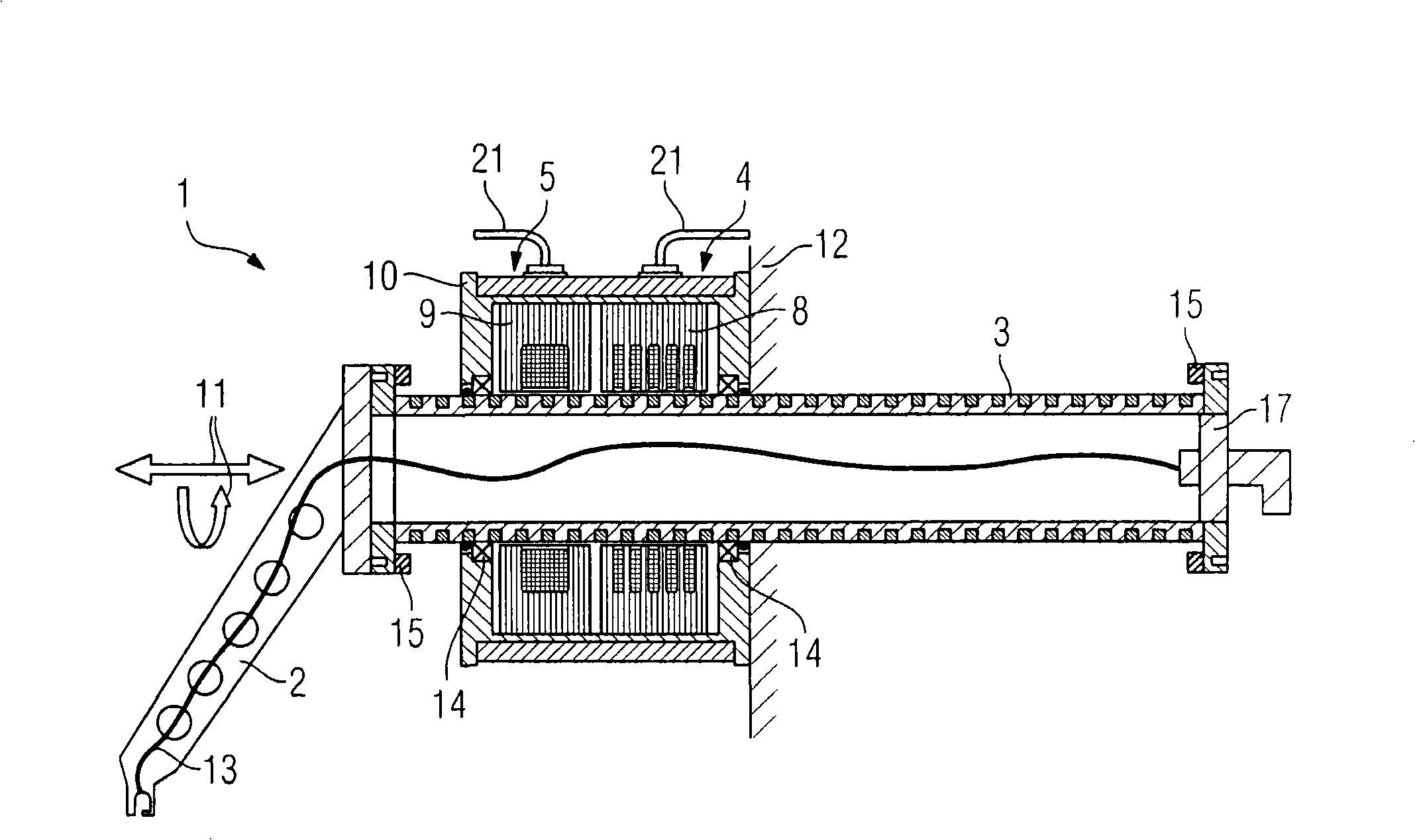

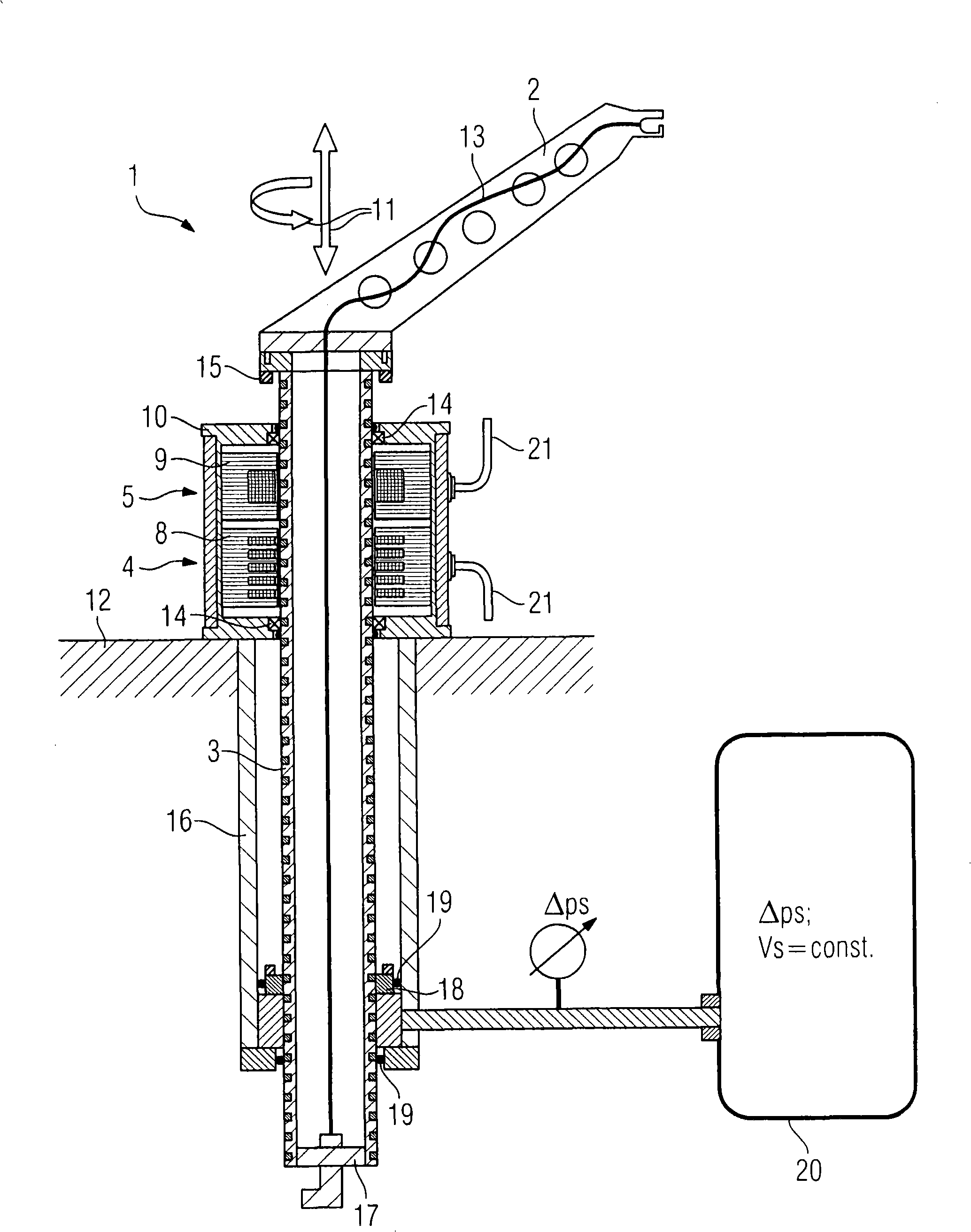

[0032] figure 1 A first embodiment of the tool changing device 1 according to the invention is shown. The tool changing device has a tool changing robot 2 and a lifting and swiveling actuator 3 for carrying out the lifting and swiveling movements. The lifting and swivel actuator 3 can be driven by means of two direct drives 4, 5, wherein the first direct drive 4 is used to generate a linear movement (lifting movement) and the second direct drive 5 is used to generate a rotary movement (swivel movement). sports). The direction of movement of the lifting and pivoting actuator 3 is indicated by arrow 11 . The lifting and pivoting actuator 3 is designed in such a way that it can be rotated through more than 360°, eg multiple turns around its own axis.

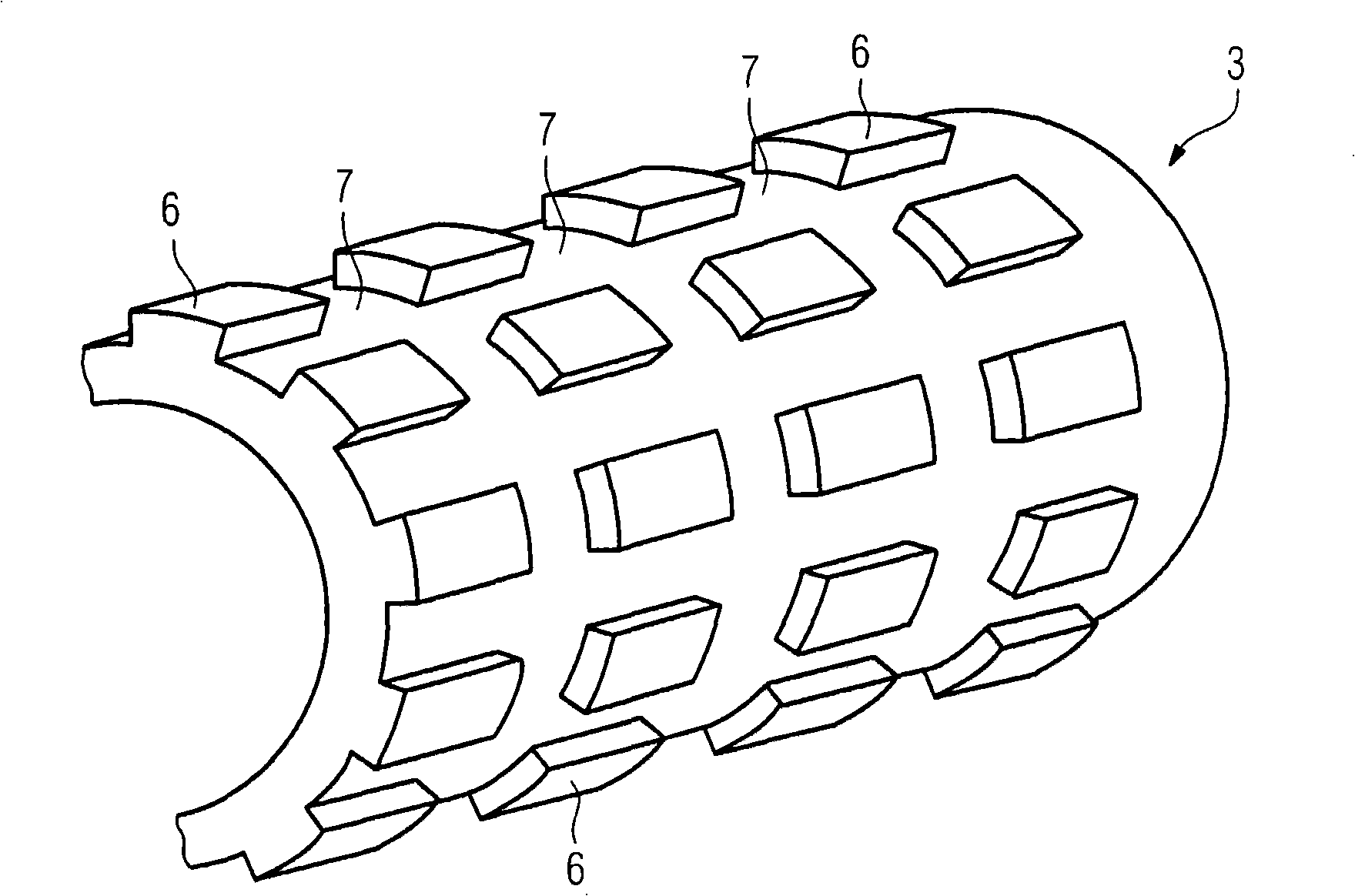

[0033] The first direct drive 4 is designed as a solenoid linear motor, that is to say a linear motor with a solenoid coil, which is also referred to as an annular or cylindrical coil. According to its working principle and mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com