Chemical vapor deposition reactor and chemical vapor deposition method

A technology of chemical vapor deposition and reactor, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as poor reproducibility and consistency, complicated control process, and low chemical vapor reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

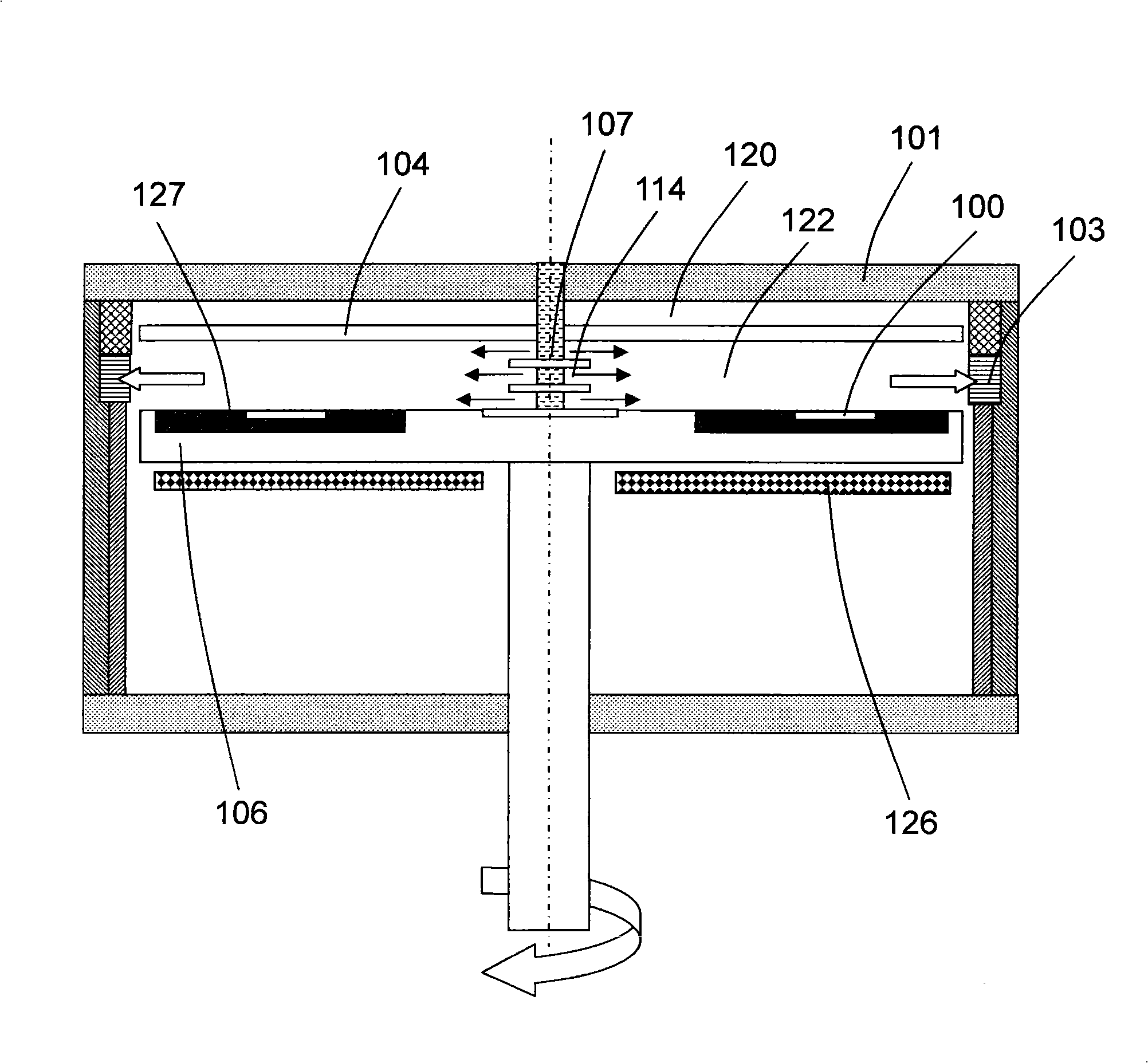

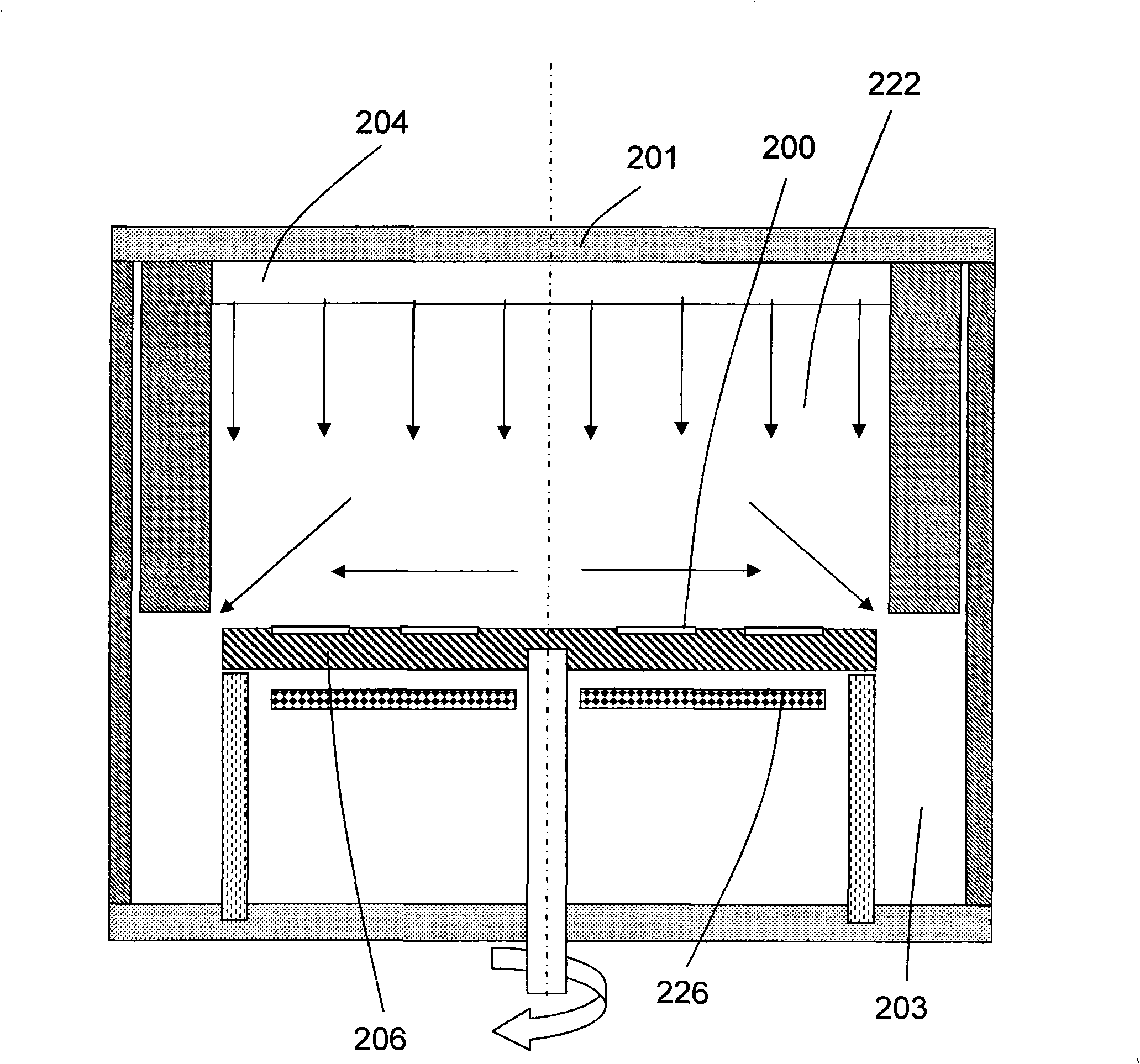

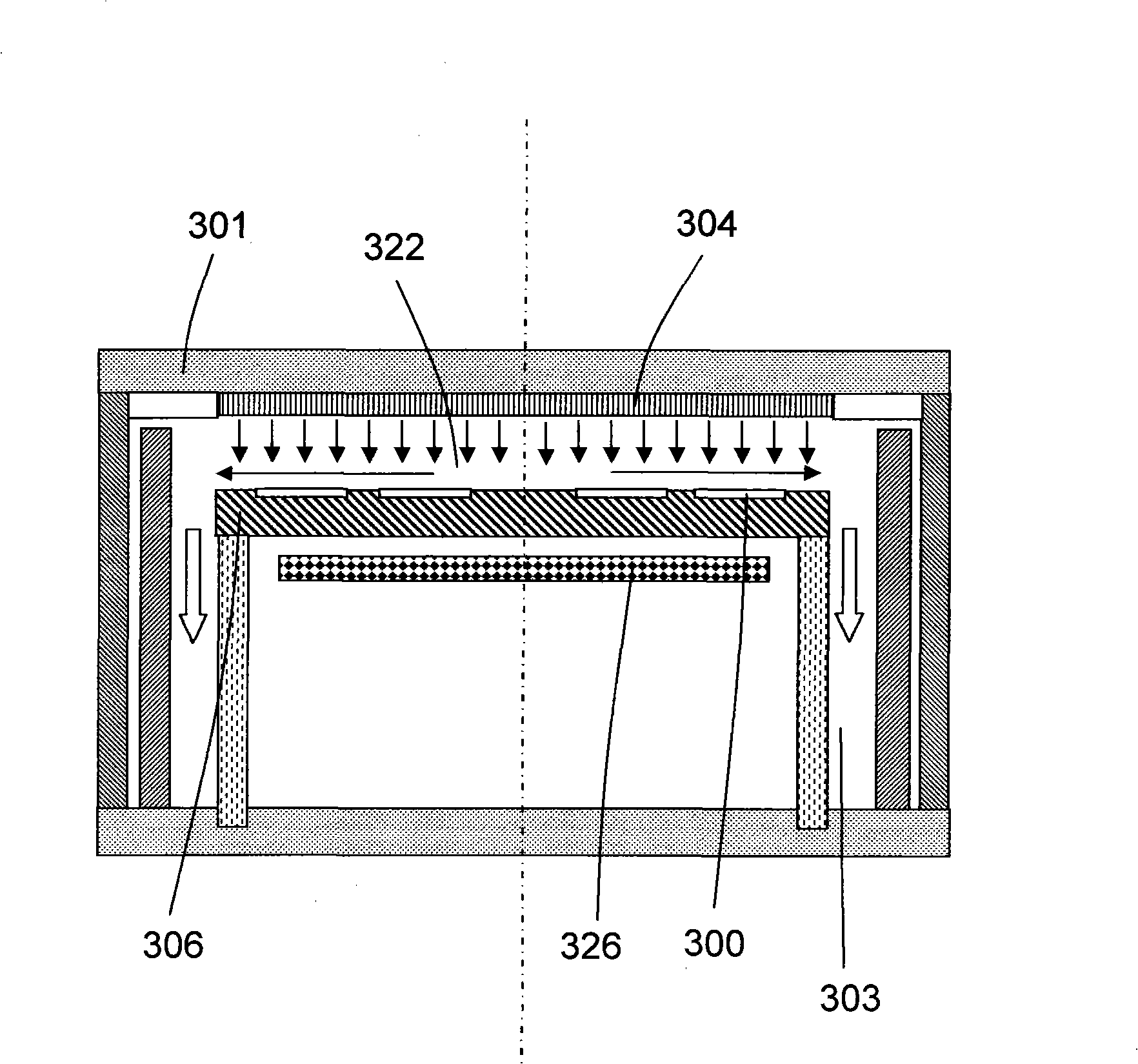

[0031] According to one embodiment of the present invention, a chemical vapor deposition reactor generally has a cylindrical reaction chamber 522 (see Figure 5 ). The cylindrical reaction chamber 522 has a reaction chamber top cover 501, a reaction chamber chassis 513, a cylindrical reaction chamber side wall 511, a cylindrical top cover support 502, an annular substrate carrier 506, A substrate carrier supporting round tubes 540a and 540b, a gas introduction ring 507, an annular gas discharge channel 503b, a heating device 526 placed under the annular substrate carrier, and a The exhaust hole 509 near the chassis of the reaction chamber.

[0032] The cylindrical top cover support 502 is generally placed at the center of the reaction chamber chassis 513, and the centers of the cylindrical top cover support 502 and the cylindrical reaction chamber 522 are usually coincident (concentric circle placement). The top of the cylindrical top cover support 502 is supported to the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com