Installation construction method of aluminum alloy window equipped with steel auxiliary frame

A technology of aluminum alloy windows and construction methods, applied in the direction of windows/doors, frame fixing, building components, etc., can solve problems such as unsatisfactory effects, and achieve the effect of uniform and reasonable peripheral gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

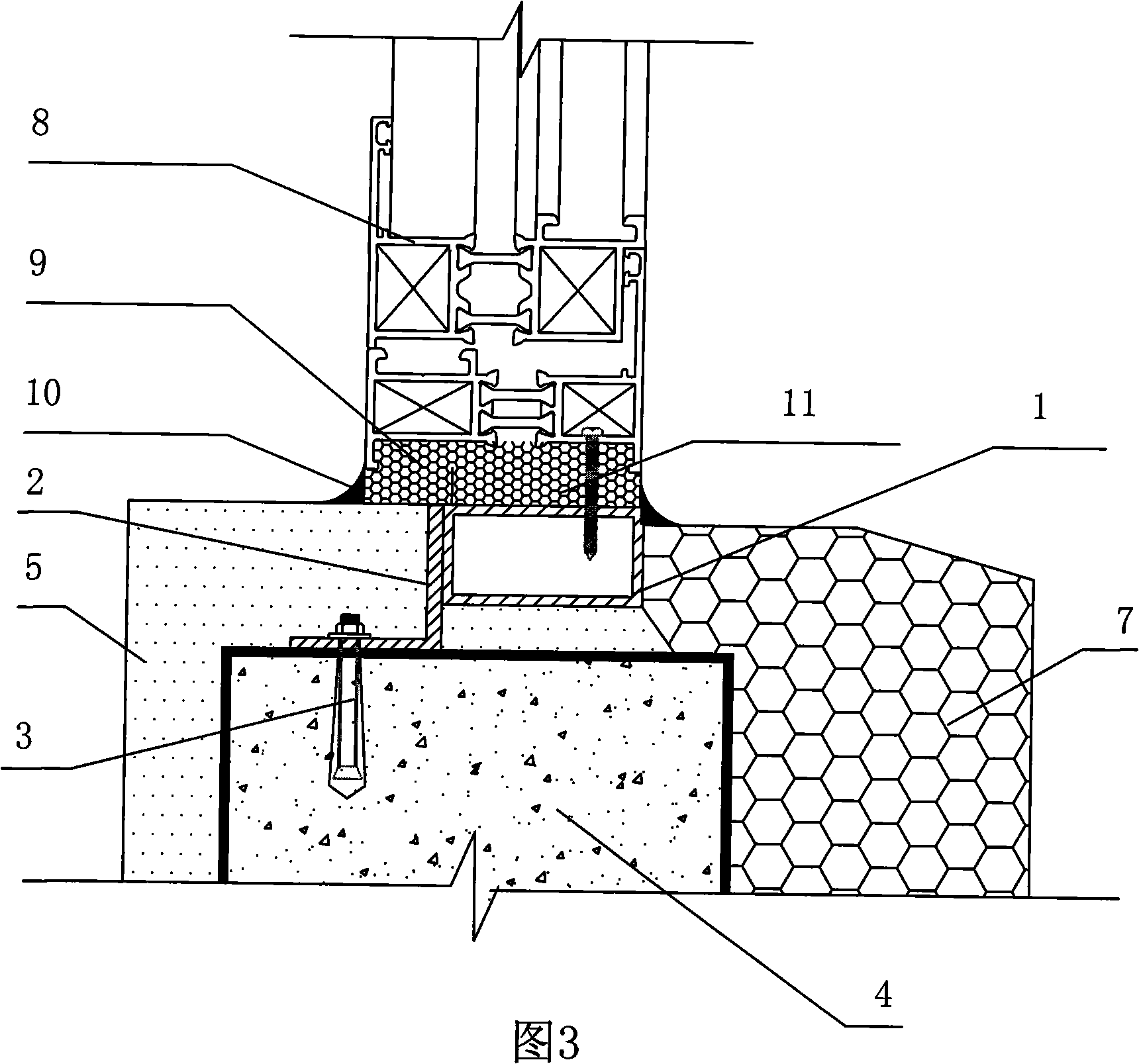

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] (1) Processing and production of steel sub-frame

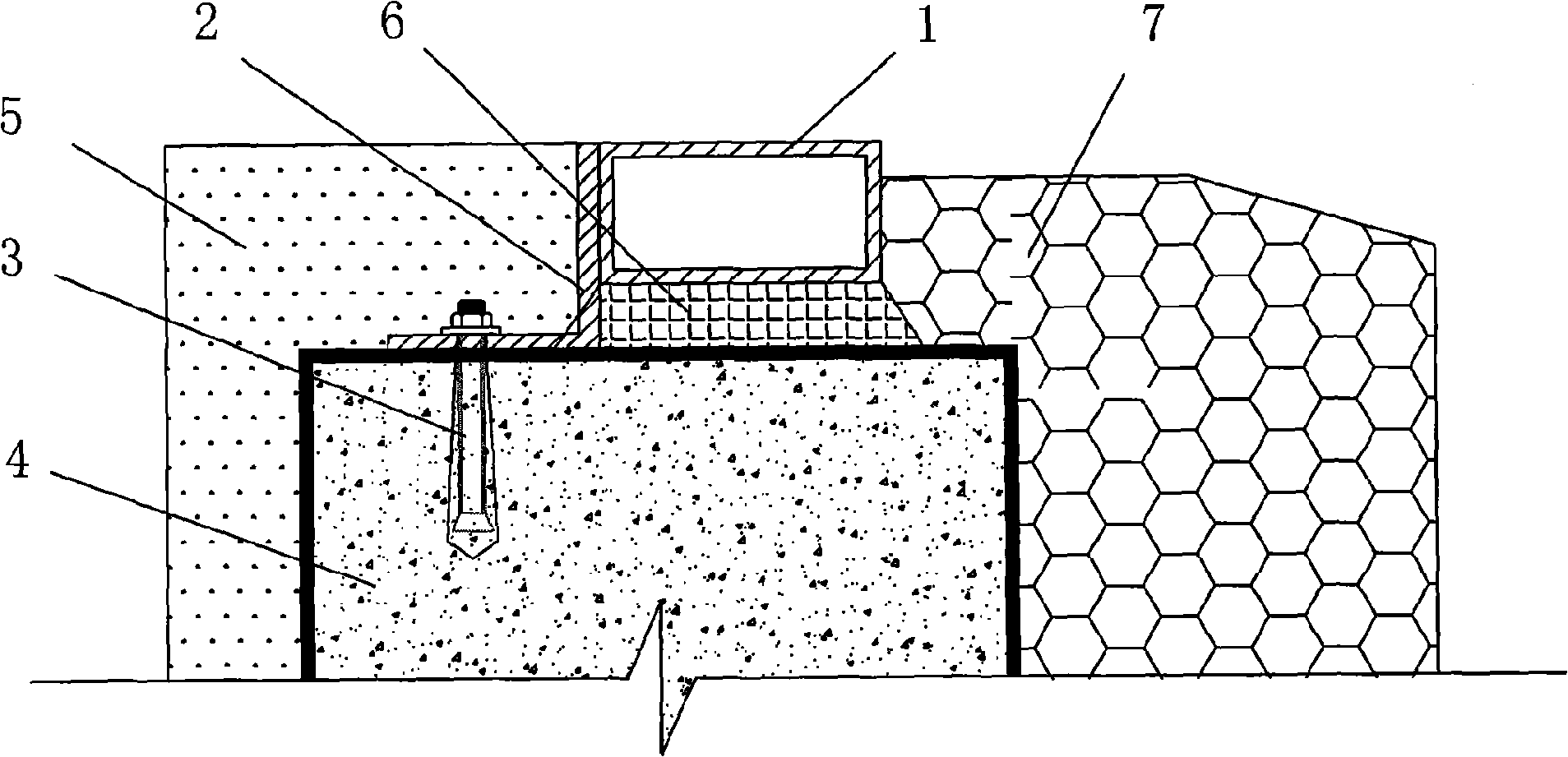

[0021] Design the size of the steel sub-frame 1 according to the size of the aluminum alloy window, which is 18-22 mm larger than each side of the reserved window opening for civil engineering. 2 (40*40*2 galvanized angle steel with a length of 40mm, with a 16*8 rectangular hole on one side) after welding, the number of connectors 2 on each side should not be less than 2, and the distance between the end and the window frame is 100-150mm, the distance between each fixed connector 2 is 200-400mm, and the solder joints must be supplemented with zinc.

[0022] (2), the installation of steel sub-frame

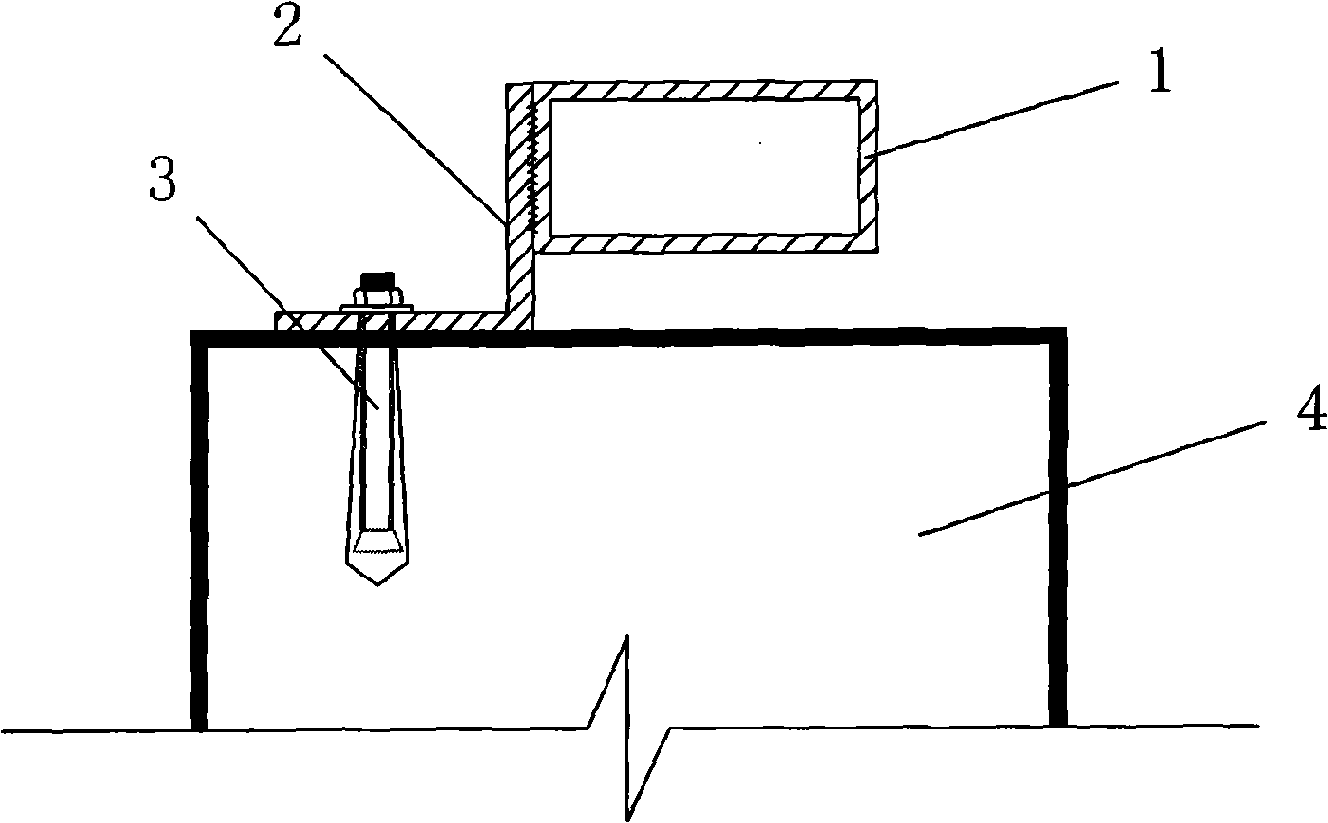

[0023] see figure 1 , according to the elevation line and the center line of the window hole, connect the steel sub-frame 1 with the side wall 4 of the window hole through the expansion bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com