Measuring apparatus and test method for volume elastic modulus of solid buoyancy material

A bulk elastic modulus, measuring device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of inability to measure bulk elastic modulus, low detection efficiency of solid buoyant materials, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

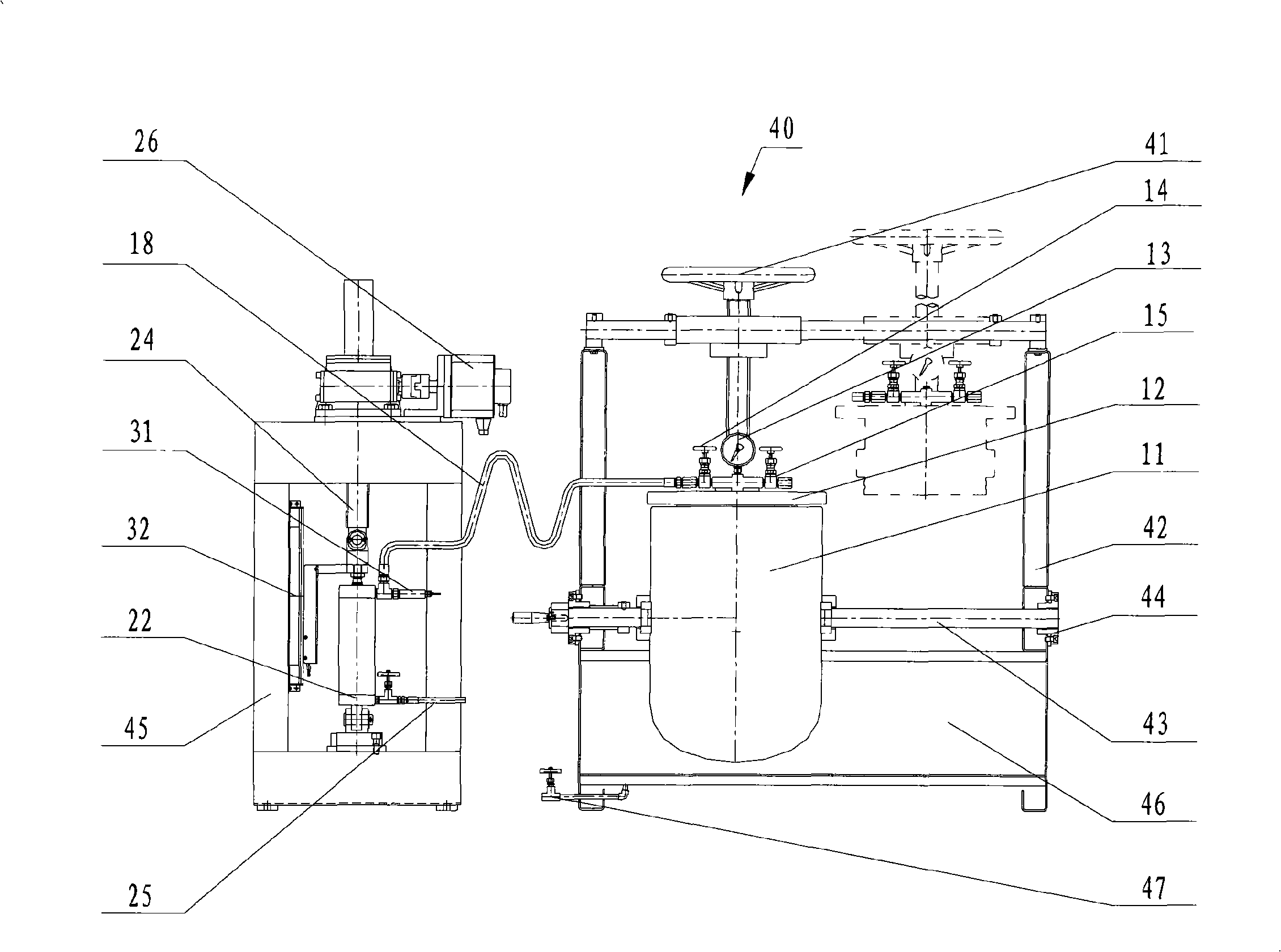

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

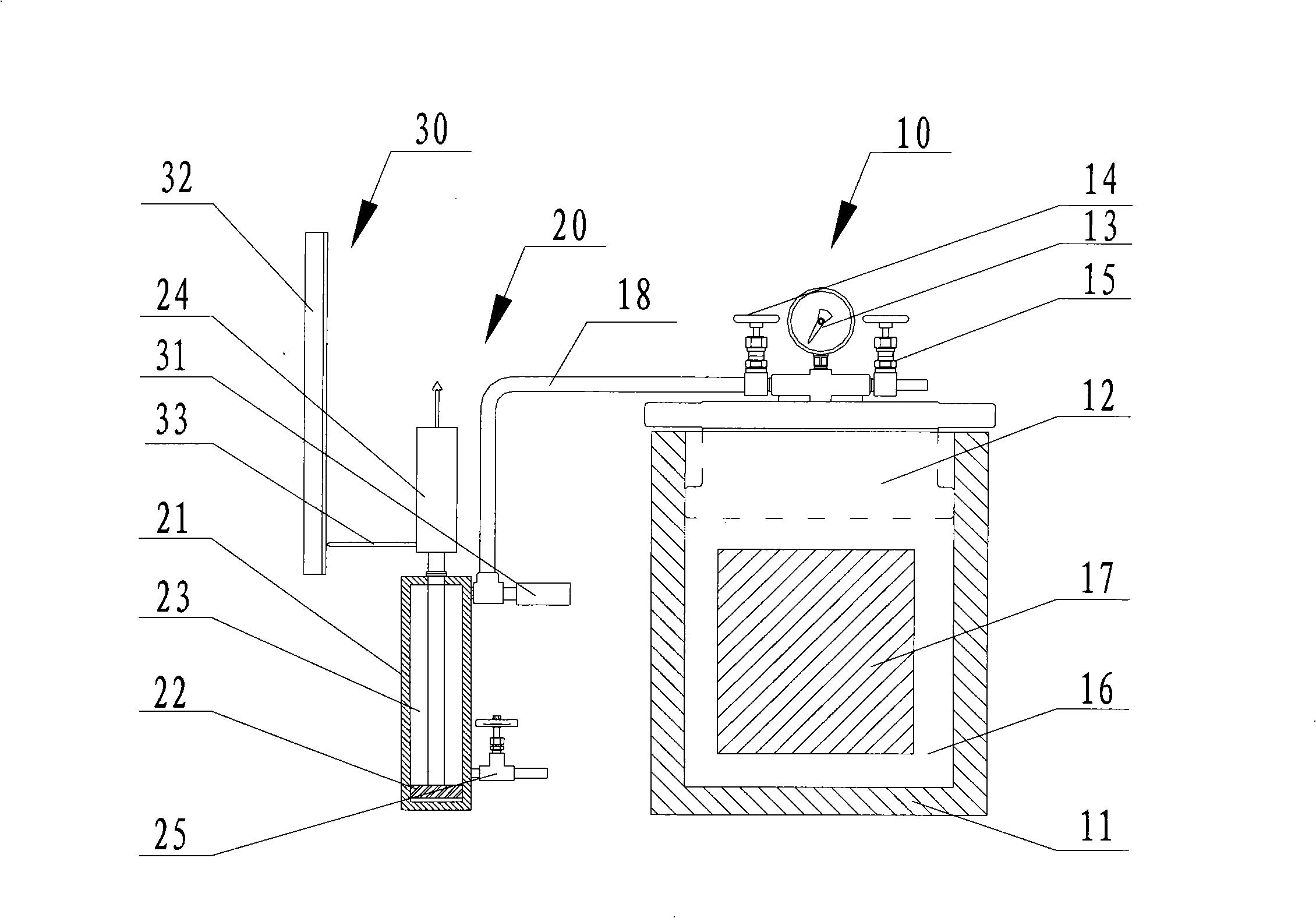

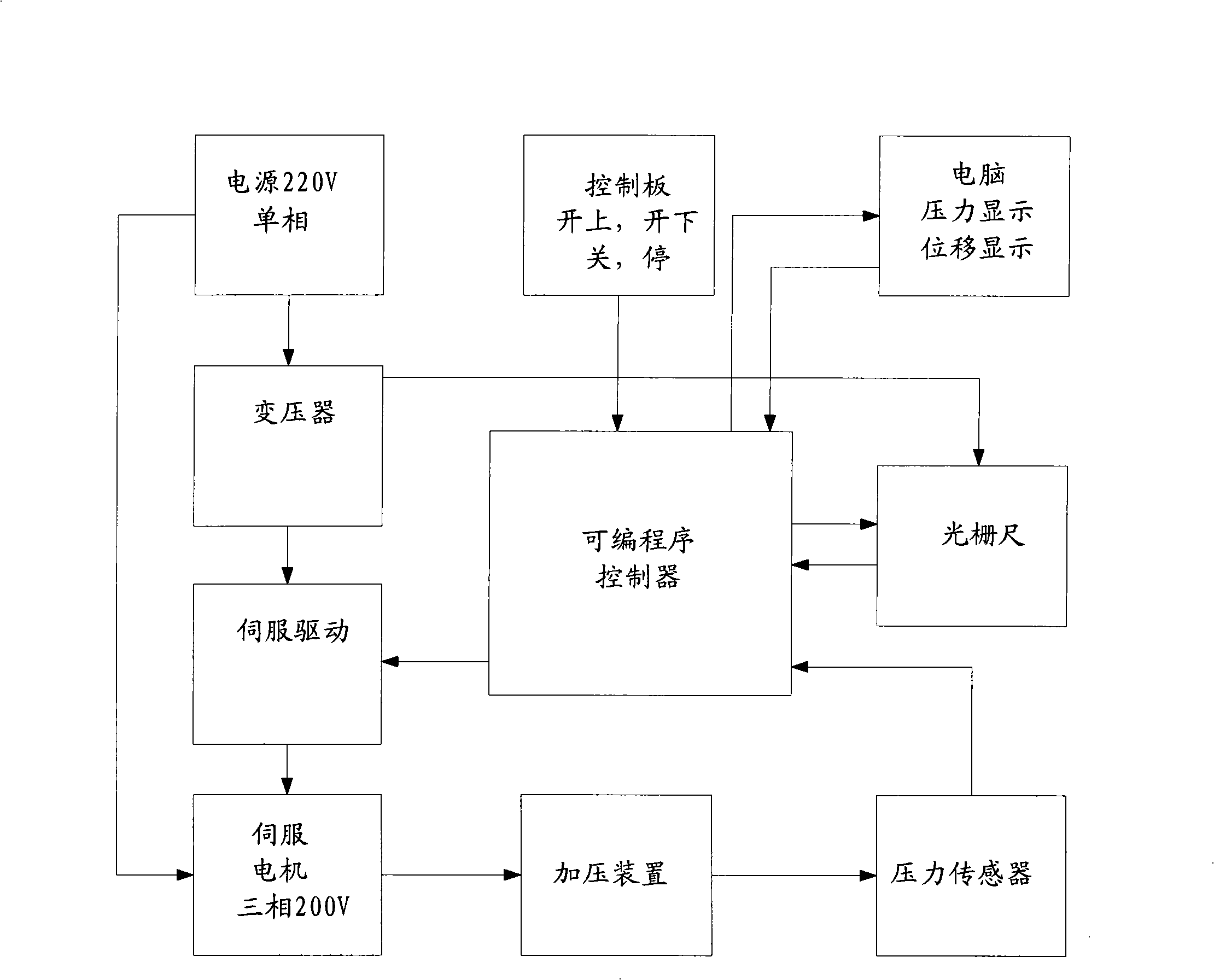

[0058] Such as figure 1 As shown, the solid buoyant material bulk modulus testing device of the present invention is mainly composed of three parts: a carrying device 10, a pressure regulating device 20 and a measurement control device 30,

[0059] The carrying device 10 includes a hydraulic cylinder 11 and its hydraulic cylinder cover 12, a pressure gauge 13 is arranged on the upper part of the hydraulic cylinder cover 12, and a pressurizing valve 14 and a pressure relief valve 15 are respectively arranged on the left and right sides of the pressure gauge 13; A calibration steel block 17 is preset, and the volume of the calibration steel block 17 is equal to the volume of the solid buoyancy material to be tested.

[0060] The pressure regulating device 20 includes a hydraulic pump 21 and its plunger 22, the lower end of the hydraul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com