Detection method for deformation magnesium alloy solvent impurity

A technology for deforming magnesium alloys and flux inclusions, applied in the direction of analysis using chemical indicators, etc., can solve problems such as difficulty in observing the formation of white silver chloride precipitation, low efficiency, and complicated operations

Active Publication Date: 2010-08-11

北京广灵精华科技有限公司 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although Cl - with Ag + It is the most rigorous judgment method to judge the existence of flux inclusions by qualitative reaction, but this method has the disadvantages of complicated operation and low efficiency, especially for alloys with many corrosion spots and few corrosion products, not only low efficiency, but also very Difficult to observe the formation of white silver chloride precipitate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Login to View More

Abstract

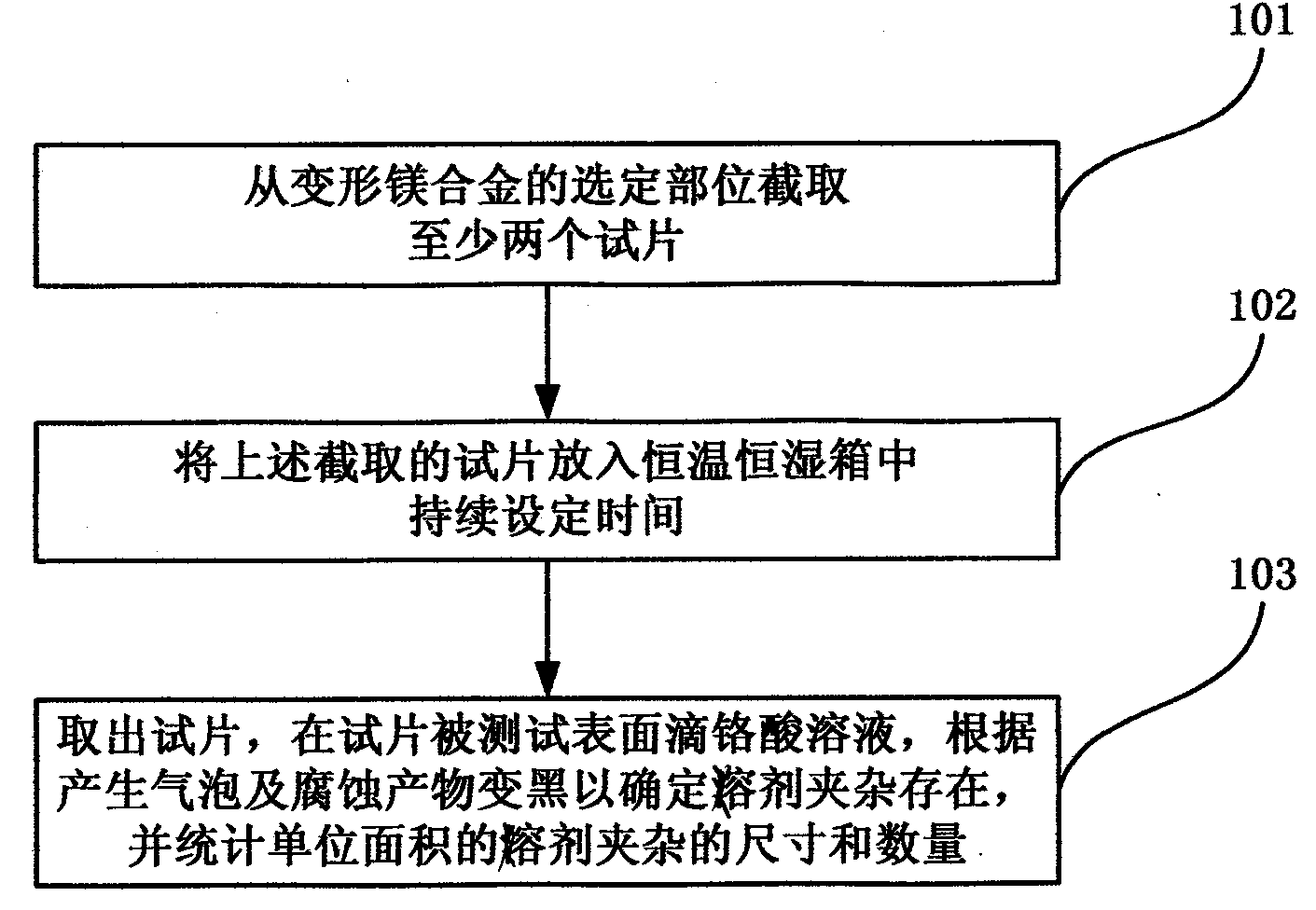

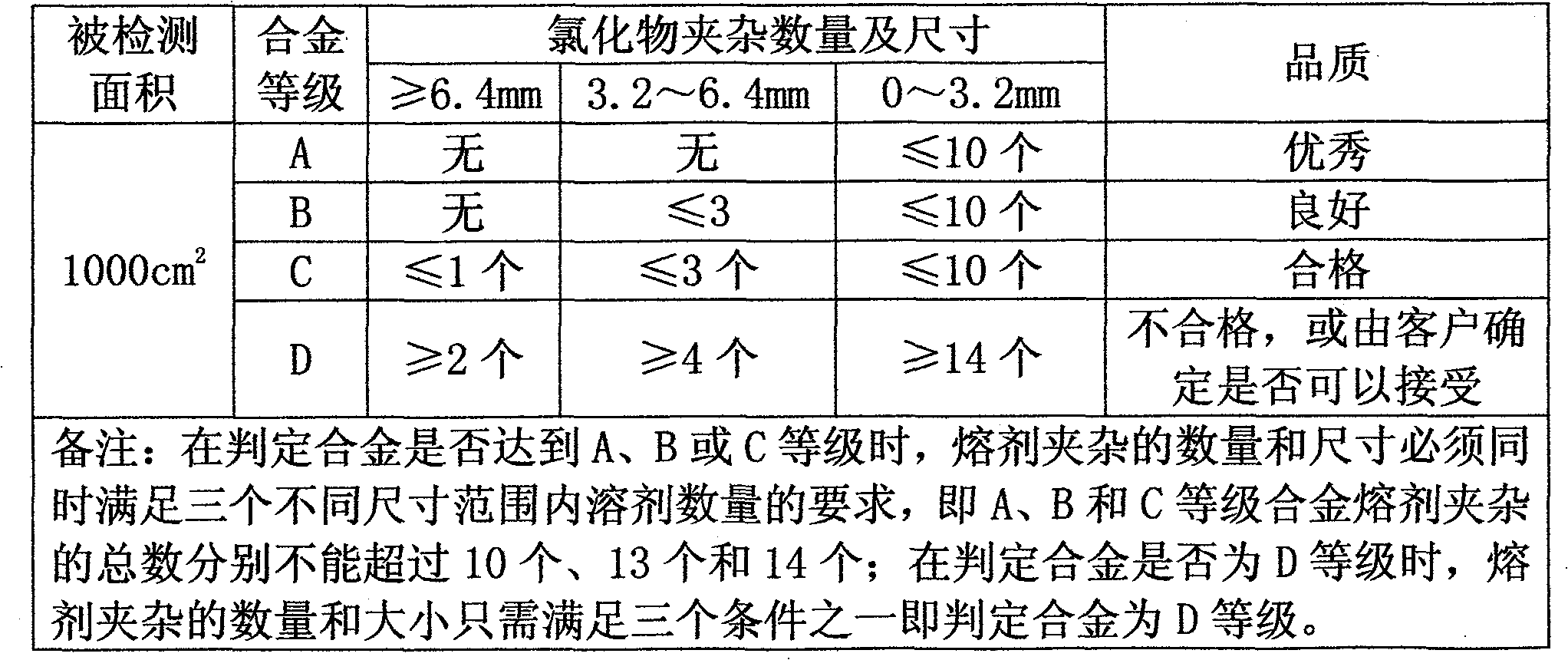

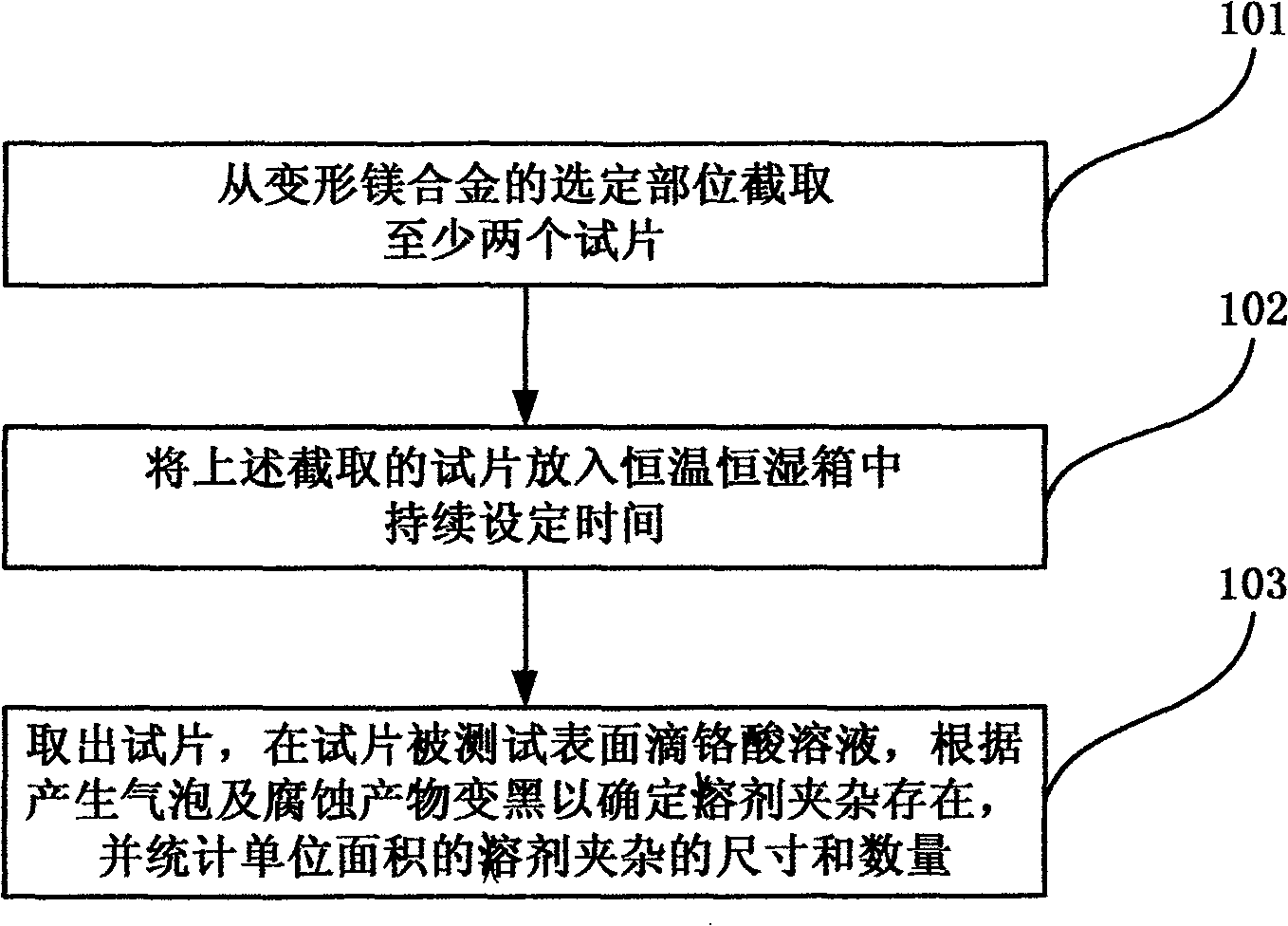

The invention discloses a detection method used for detecting impurities in a deformation Mg-alloy solvent, comprising the steps as follows: at least two test pieces are intercepted at the selected position of a deformation Mg-alloy; the intercepted test pieces are arranged in a constant-temperature and constant-humidity box with the temperature of 30 to 34DEG C plus or minus 2 DEG C and the relative humidity of 87 to 94% for a given time; the test pieces are taken out of the constant-temperature and constant-humidity box; 250g / L of chromic acid solution is dripped at the white corrosion outcome on the surface to be tested of the test pieces; the existence of the solvent impurities is determined by that the air bubbles generated at the white corrosion outcome and the color of the corrosion outcome are changed to black; and furthermore, the dimension and quantity of solvent impurities of unit area is counted. The detection method used for the solvent impurities can quickly and effectively determine the quantity of the solvent impurities on a certain section, thereby being extremely suitable for the detection of impurities in the deformation Mg-alloy solvent in industrial production.

Description

technical field The invention relates to a detection method, in particular to a detection method applied to flux inclusions in deformed magnesium alloys. Background technique The so-called magnesium alloy is an alloy composed of magnesium and other elements. Its characteristics are: low density (about 1.8g / cm3), high specific strength, large elastic modulus, good shock absorption, greater impact load capacity than aluminum alloy, and good corrosion resistance to organic matter and alkali. The main alloying elements are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium. Magnesium-aluminum alloys are currently the most widely used, followed by magnesium-manganese alloys and magnesium-zinc-zirconium alloys. Mainly used in aviation, aerospace, transportation, chemical industry, rocket and other industrial sectors. According to the forming method, it is divided into two types: wrought magnesium alloy and cast magnesium alloy. Flux inclusi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N31/22

Inventor 仝仲盛李胜凯牛强

Owner 北京广灵精华科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com