Triangular gridding subdivision curved surface NC tool track fast generation method

A triangular mesh and subdivision surface technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of restricting the generation efficiency of CNC machining tool paths, lack of space data index structure of triangular mesh subdivision surface model, etc., to achieve The effect of improving generation efficiency, improving generation accuracy, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

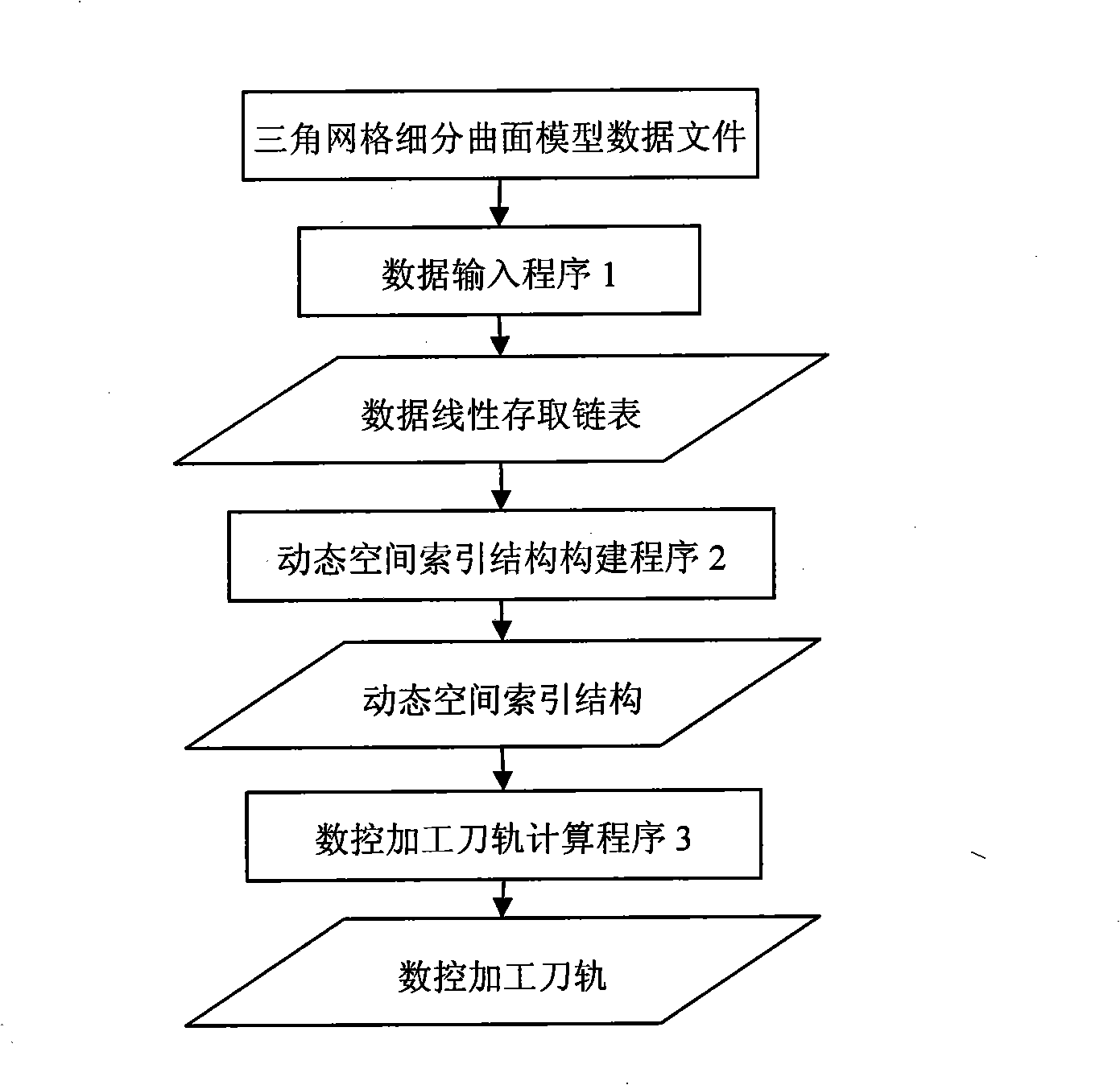

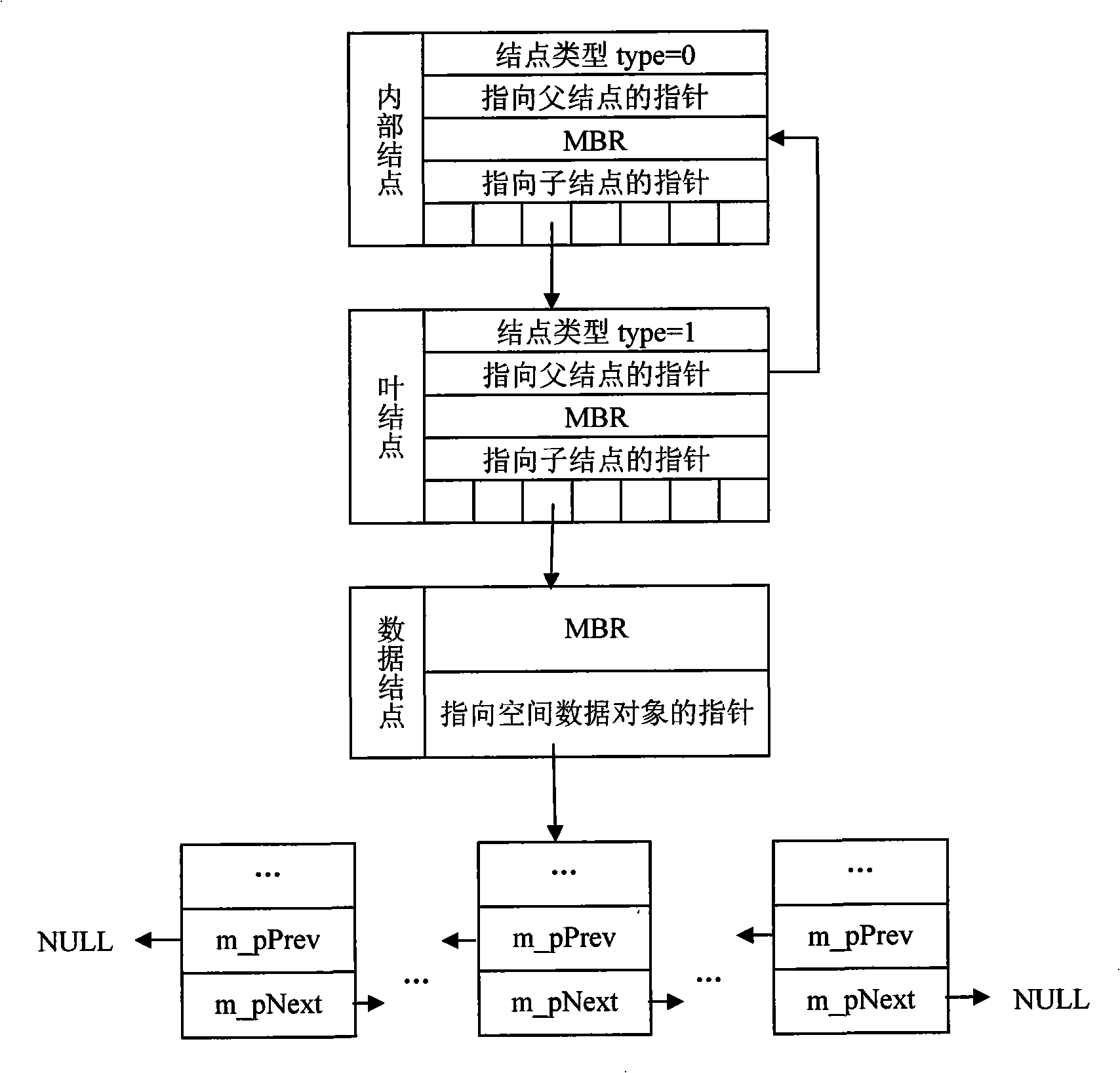

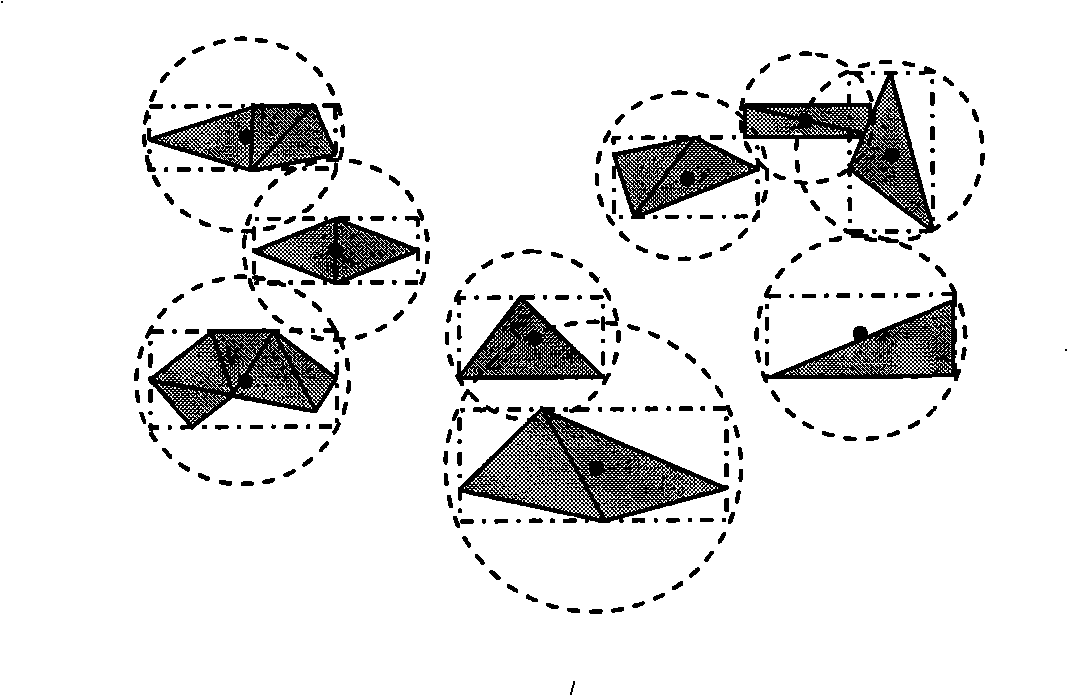

[0029] Adopt C language to realize the generation of triangular mesh subdivision surface model numerical control machining tool path, the realization flowchart of triangular mesh subdivision surface model numerical control machining tool path generation program of the present invention is as attached figure 1 shown. The data input program 1 is responsible for reading in the triangular mesh subdivision surface model data, and creating a linear linked list storage structure for it to support the linear sequential traversal of the triangular mesh data. Triangular grid subdivision surface model spatial clustering index structure construction program 2 uses nested 3D rectangles to perform dynamic spatial clustering on point cloud data, and establishes an upper-level improved R for the data linear linked list generated by data input program 1 * -tree spatial clustering index str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com