Ultraviolet irradiation apparatus

An irradiation device and ultraviolet technology, which are applied to irradiation devices, lighting devices, lighting auxiliary devices, etc., can solve the problems of increasing the separation distance of the support body, increasing the distance of the support substrate 2, and the power source 41 and the transformer 42 reaching heat-resistant temperature damage. , to achieve the effect of suppressing the temperature rise and not increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the ultraviolet irradiation device of this invention is demonstrated using drawing.

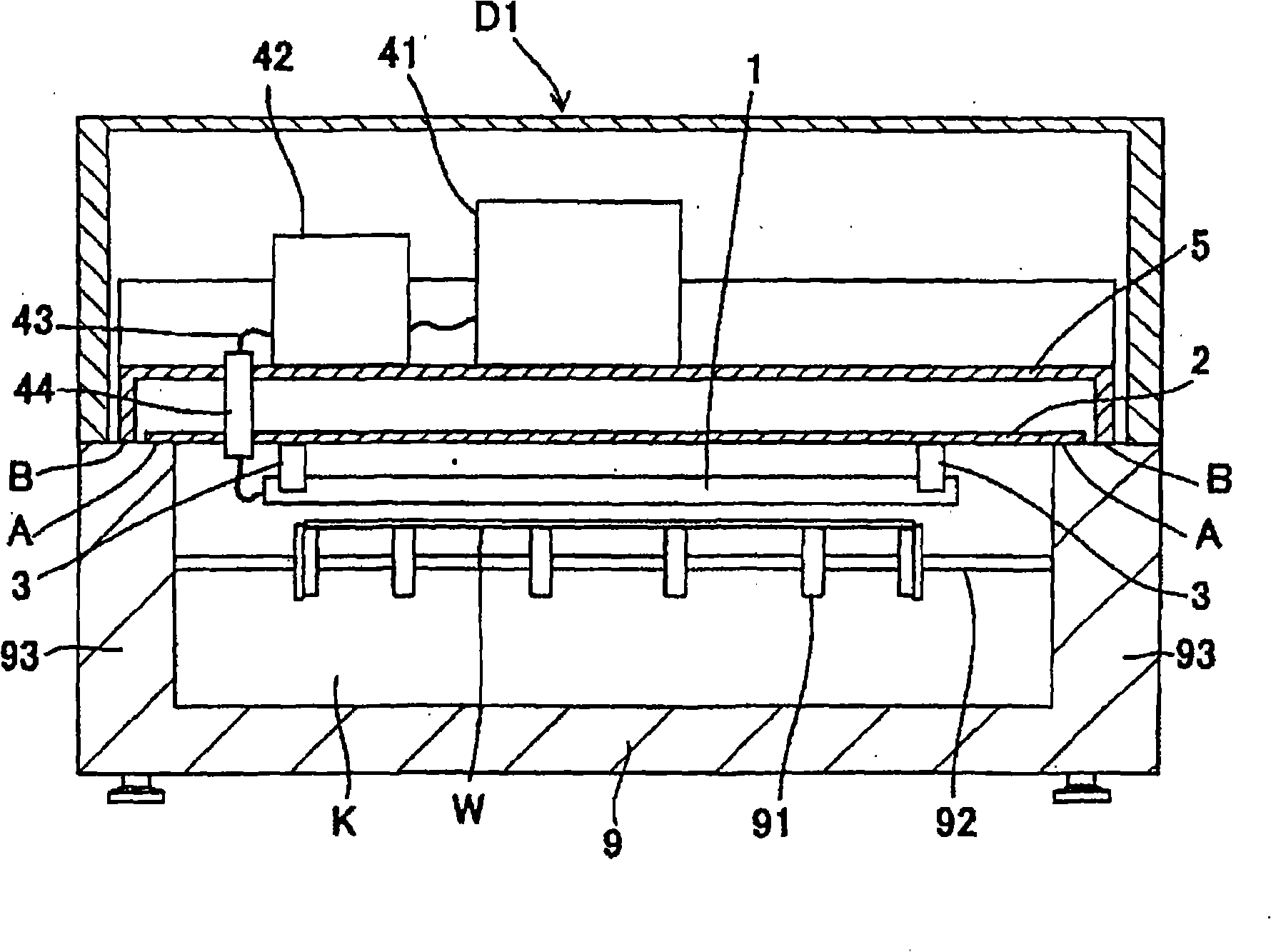

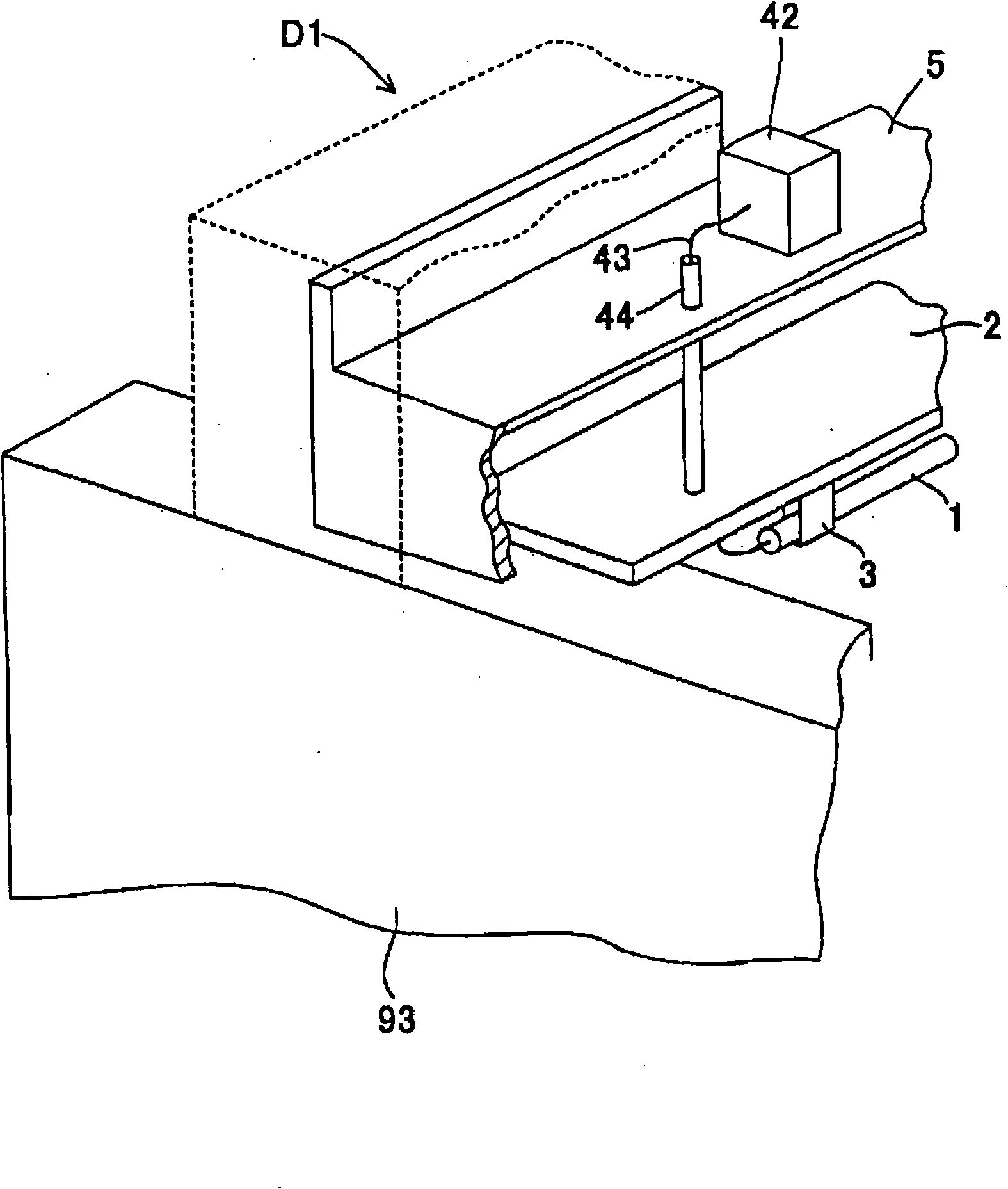

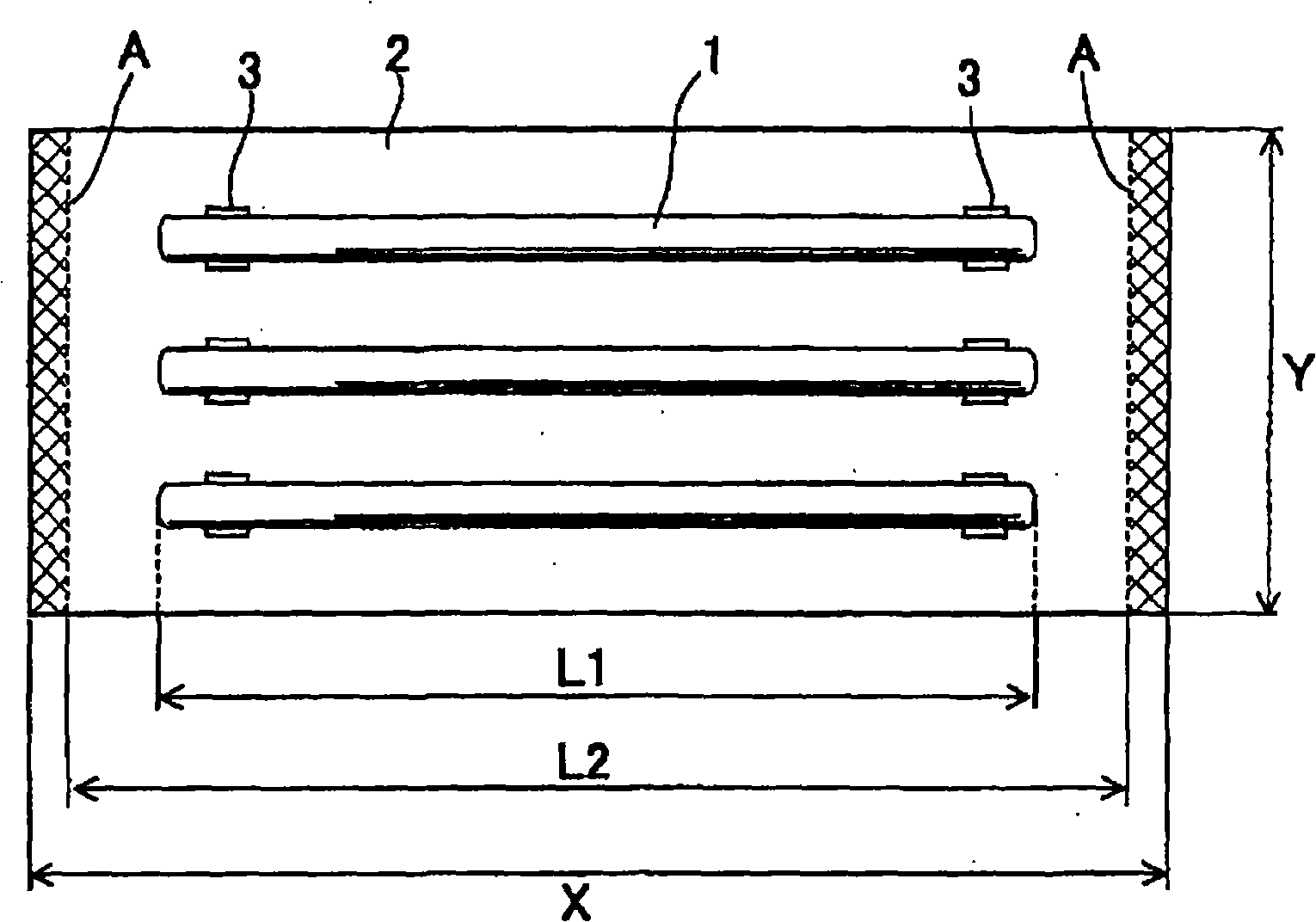

[0048] figure 1 It is a structural explanatory diagram in which the ultraviolet irradiation device of the present invention is arranged on the processing chamber, figure 2 is viewed from above the processing chamber figure 1 Partial cut-away perspective view of the ultraviolet irradiation device of , image 3 It is viewed from the direction of the ultraviolet light figure 1 A top view of the UV irradiation setup.

[0049] Such as figure 1As shown, the processing chamber 9 is the same structure as the processing chamber described in the prior art, and has a processing space K with an upper opening. In the processing chamber 9, a conveying roller 91 is installed on a roller shaft 92, and the conveying roller 91 is rotated to convey The processed object W is irradiated with ultraviolet rays to treat the processed object.

[0050] In addition, in the treatment chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com