Joint product between steel product and aluminum material, spot welding method for the joint product, and electrode chip for use in the joint product

A joint, aluminum alloy technology, applied in electrode features, welding/welding/cutting items, welding equipment, etc., can solve the problems of poor spot weldability, decreased joint strength of dissimilar material joints, and reduced joint strength at the starting point of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

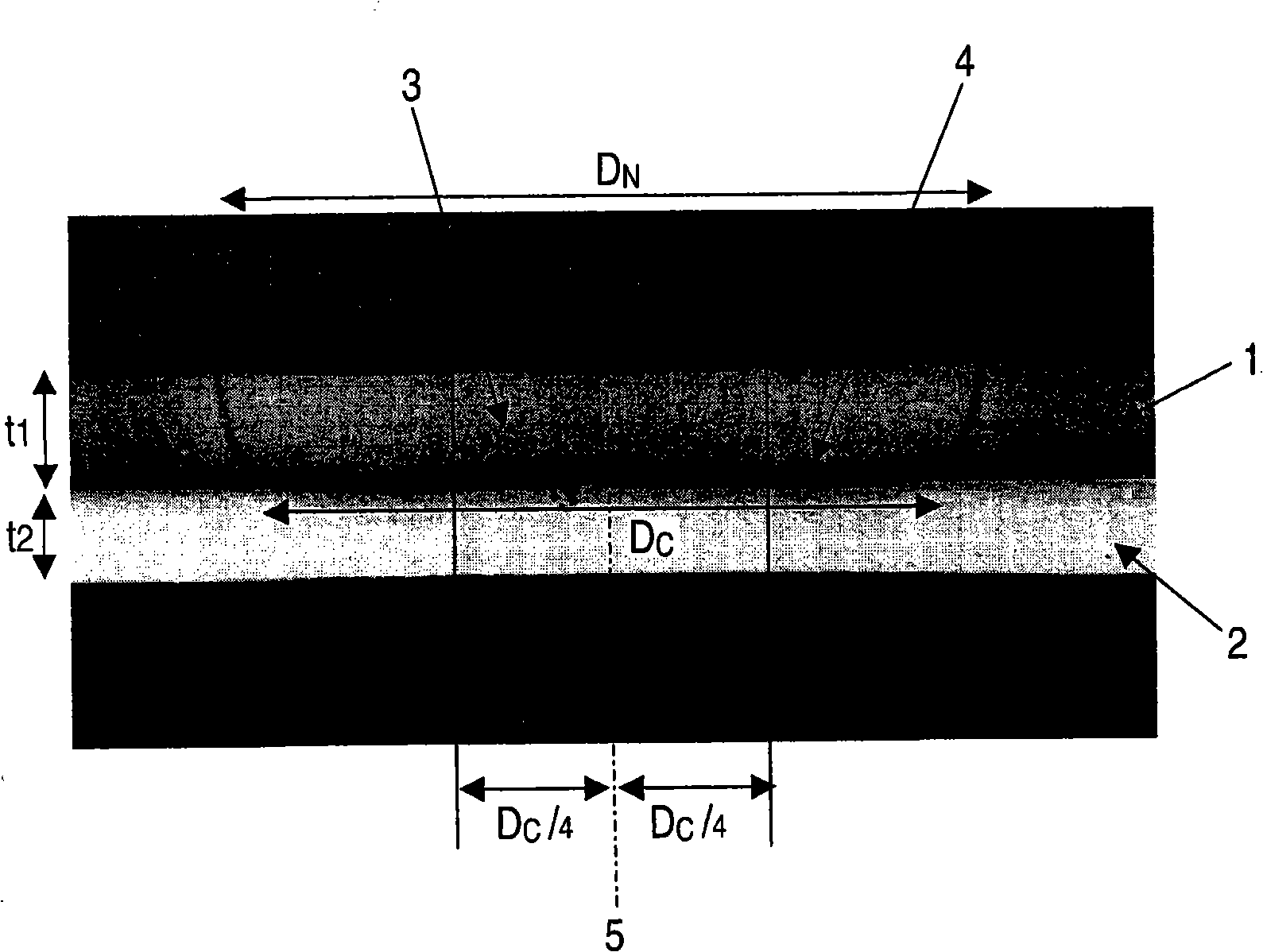

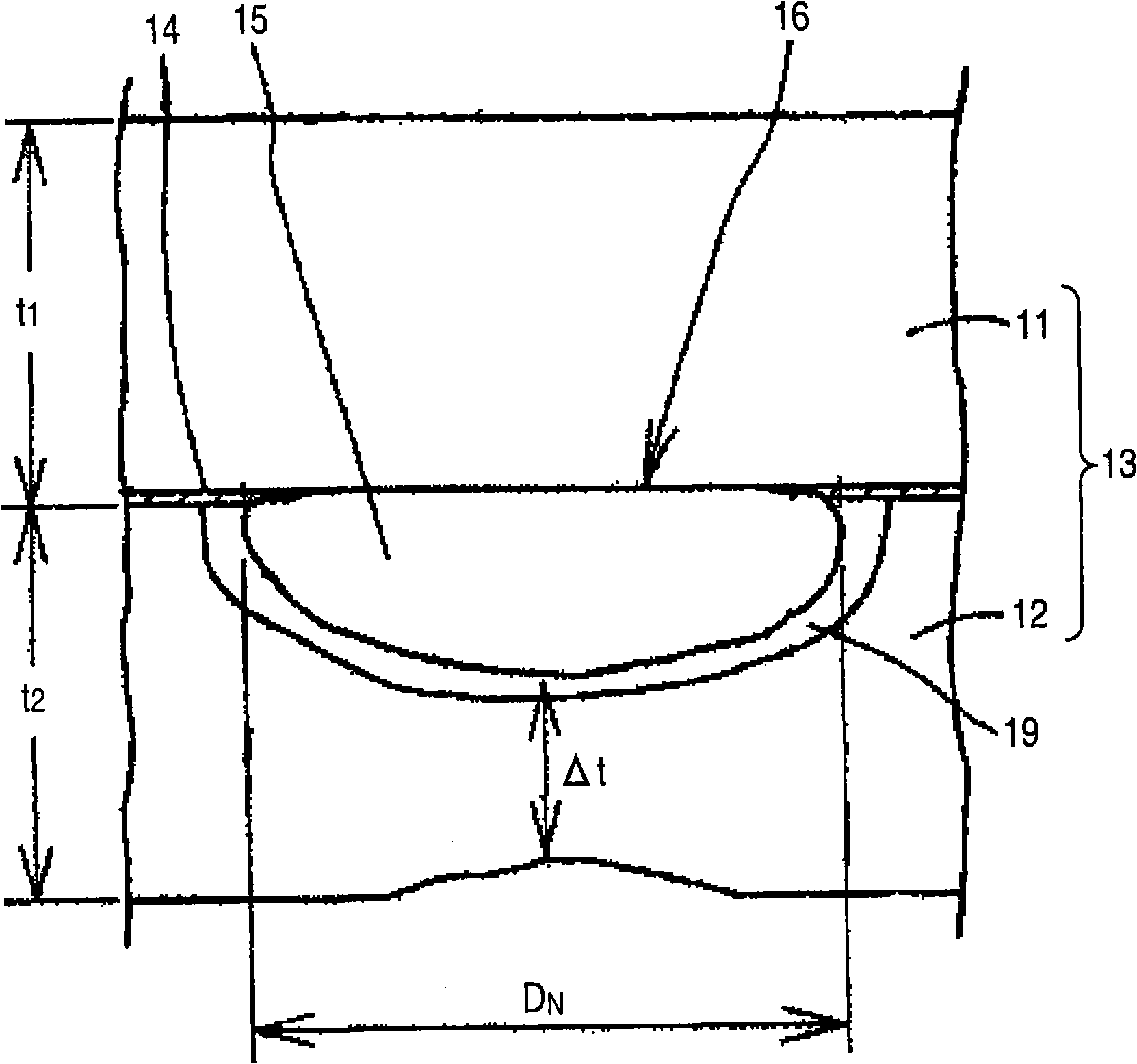

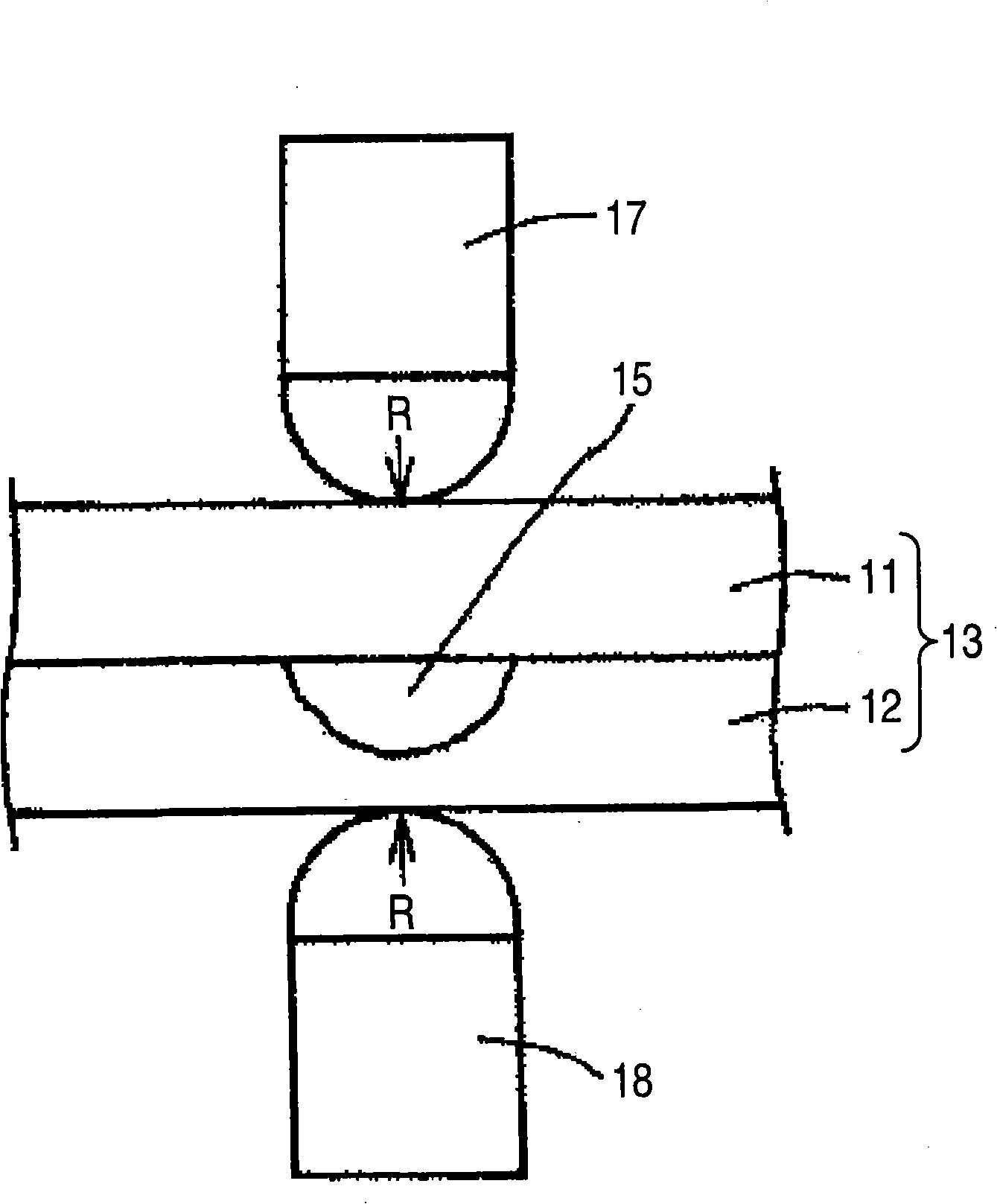

[0172] As steel materials, steel sheets obtained as follows were used. That is, cast a test ingot containing 0.06%C-0.5%Si-1.2%Mn by mass as a chemical composition, except for inevitable impurities such as P and S, and the remainder is substantially Fe, and roll it A thin steel plate was obtained up to a plate thickness of 1.2 mm. In addition, in continuous annealing, after annealing at 500 to 1000° C., oil washing or water washing is performed, and then tempered to obtain a 590 MPa-class high-strength steel sheet.

[0173] In addition, as the aluminum material, two types of commercially available A6022 (6000 series) aluminum alloy plates having a plate thickness of 1.0 mm and 1.6 mm were used.

[0174] These steel sheets (steel materials) and aluminum alloy sheets (aluminum materials) were processed into the shape of cross tensile test specimens described in JIS A 3137, and then welded to produce dissimilar joints. The steel plate and the aluminum alloy plate were cooled in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com