Refrigeration device

A refrigeration device and unit technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reduced reliability of refrigeration devices, reduced refrigerant circulation, and reduced pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

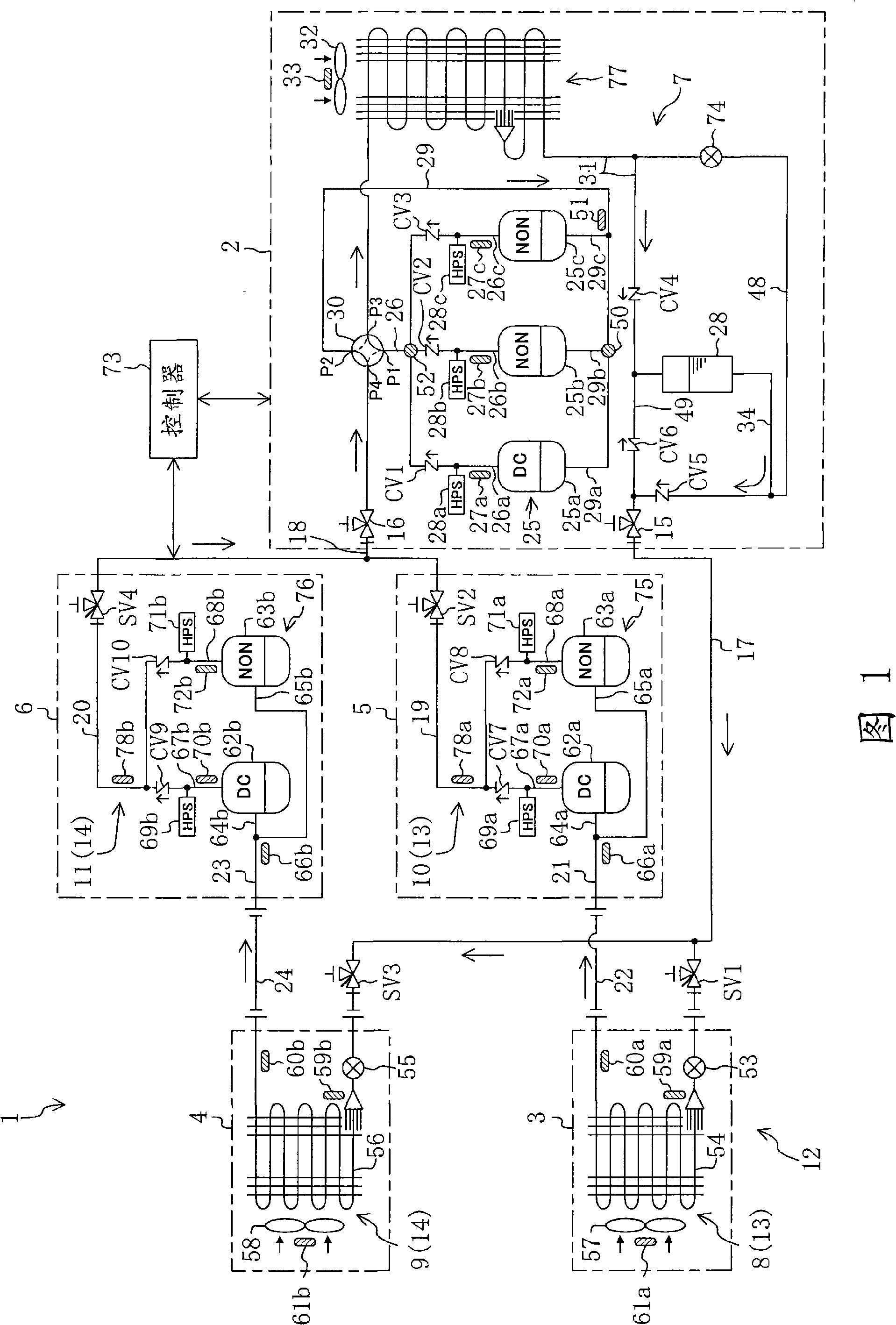

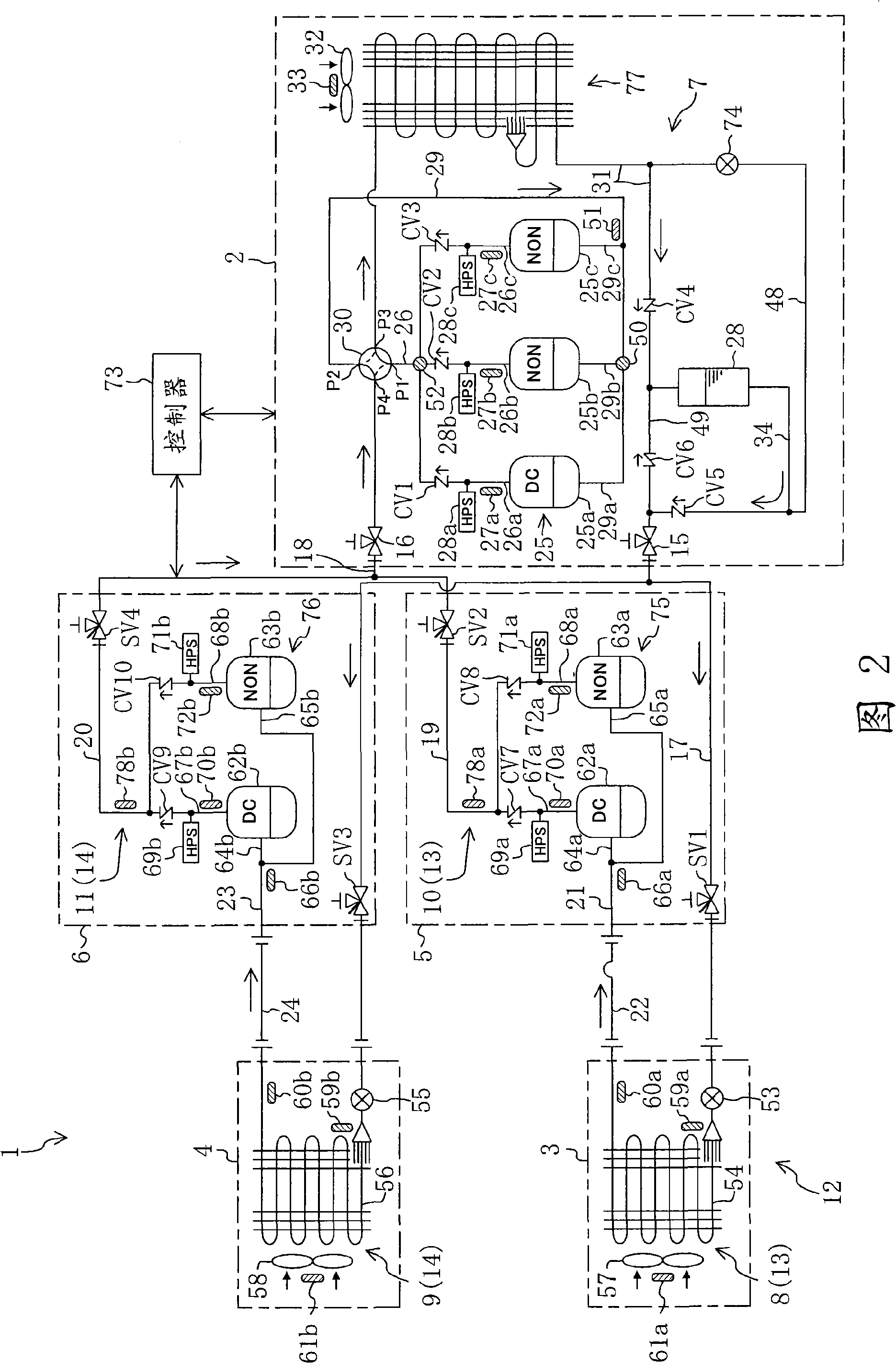

[0026] Embodiments of the present invention will be described in detail below with reference to the drawings.

[0027] This embodiment shown in FIG. 1 relates to the refrigeration apparatus 1 which performs cooling operation in two freezers.

[0028] The freezer 1 has an outdoor unit (heat source side unit) 2 installed outdoors, a first storage unit (first utilization side unit) 3 and a second storage unit (second utilization side unit) installed in the freezer. ) 4, the first booster unit 5 and the second booster unit 6.

[0029] An outdoor circuit 7 having a high-stage compression mechanism 25 and an outdoor heat exchanger (heat source side heat exchanger) 77 is installed in the outdoor unit 2, and an outdoor circuit 7 having a first indoor heat exchanger (the second heat exchanger) is installed in the first indoor unit 3. A first refrigerating circuit 8 using a side heat exchanger) 54, a second refrigerating circuit 9 with a second refrigerated heat exchanger (a second uti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com