Determination of gas solubility, entrained gas content, and true liquid density in manufacturing processes

A gas content, liquid technology, applied in the direction of liquid transportation, gas diffusion analysis, pulp raw material addition process, etc., can solve the problems of impracticability, solubility difference, error, etc., and achieve the effect of optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

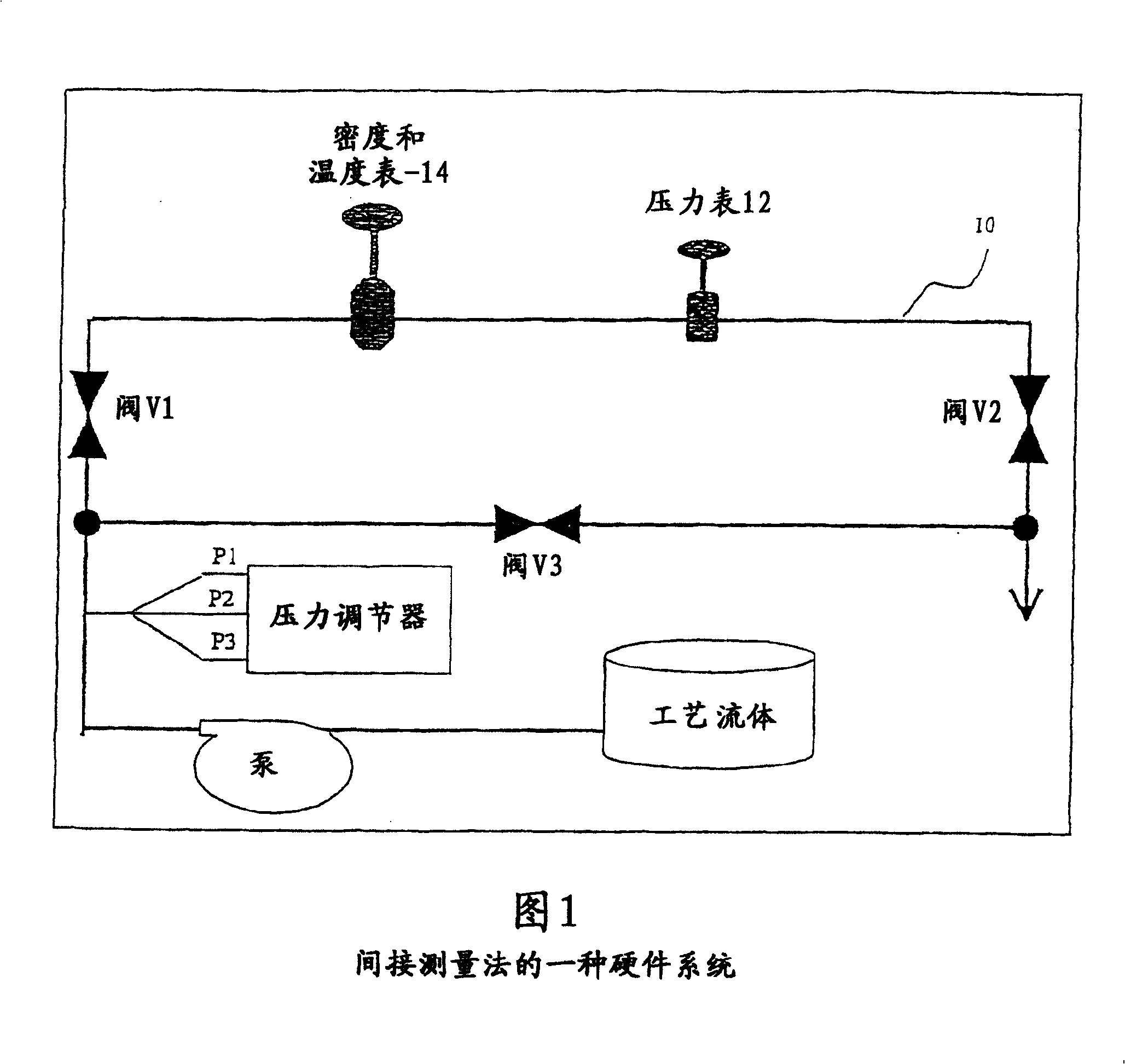

[0243] Example 1 - Entrained Air: Indirect Determination of Entrained and Dissolved Air Content in a Liquid equipment

[0244] Figure 1 depicts the specific hardware architecture for using the indirect assay setup described above. The device shown in Figure 1 was tested in the "no-flow" state. The apparatus 10 in Fig. 1 comprises a container for processing liquid from which the liquid is pumped by a piping system subject to at least three different pressure states P 1 ,P 2 ,P 3 control of the pressure regulator. Each of these pressures is greater or less than the preceding pressure. For example, the order can be P 1 2 3 , or P 1 >P 2 ,P 1 2 , or any other combination. Furthermore, these pressures can also be based on system constraints or settings of assay objects. The liquid flow in the pipeline is controlled by three valves V1, V2, V3. This particular device also includes pressure gauges 12 and density and temperature gauges 14 .

[0245] The measurement proce...

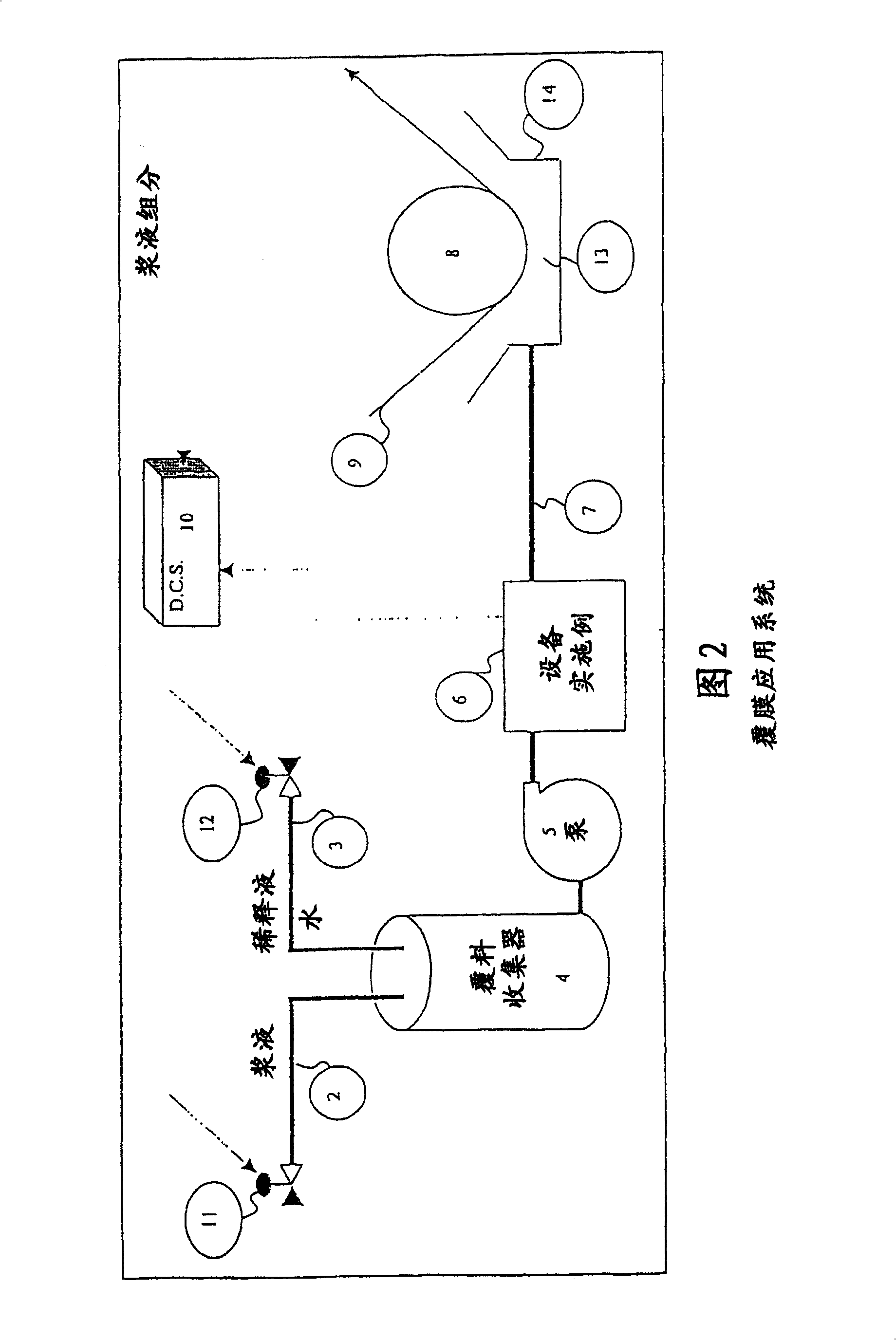

Embodiment 2

[0246] Example 2 - Entrained Air: Optimizing Degassing Operations During Lamination

[0247] During some coating operations, the environment requires extreme removal of gas entrapped in the coating liquid to be coated on the substrate. This is because air bubbles, especially large air bubbles, trapped in the fluid can deteriorate the film quality and cause peritoneal defects such as transitional stomata. With the rapid development of high-speed injection and curtain coating technology-in this new technology, a thin liquid film is not only injected but also freely covered on the substrate to be coated-any entrained large air bubbles will cause damage to the free coating. The overall destruction of the liquid film. Therefore, a degassing process is a must in high velocity jetting and curtain lamination applications.

[0248] In one application according to the present invention as shown in FIG. 5 , degassers are integrated before and after the curtain film-coated piping syst...

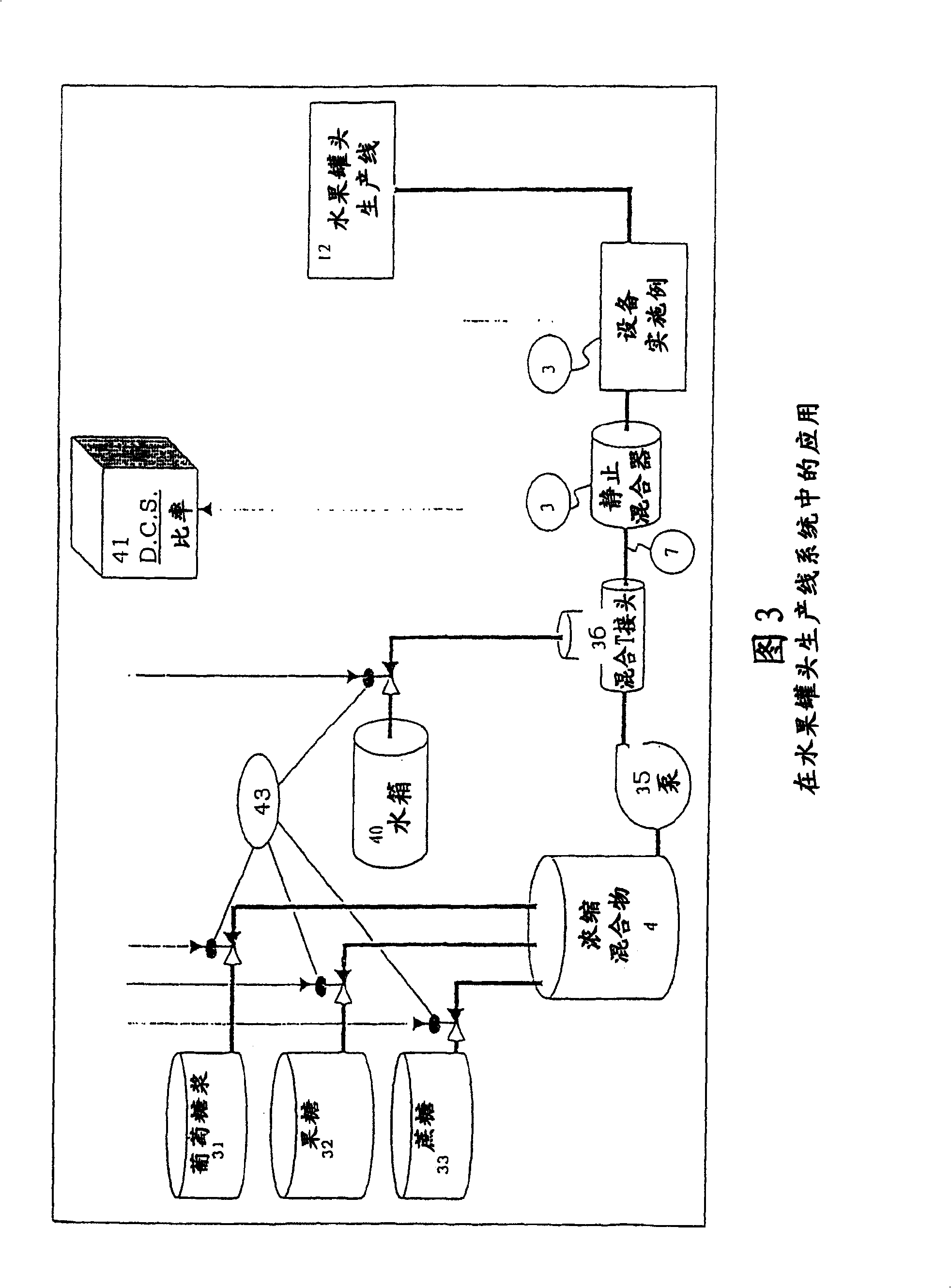

Embodiment 3

[0250] Example 3 - Air Trapping: Quality Control in Film Application Systems

[0251] In Example 2, the degassing unit can reduce waste costs by avoiding the manufacture of substandard products. When the level of percent air entrainment that would cause quality problems in the product is known, the measured percent air entrainment can be used to stop production, or can be used to predict when out-of-spec product will be produced. It is not necessary to integrate two devices ("front" and "rear") according to embodiments of the present invention on the biometric system (as shown in FIG. 5 ). Instead, a system with a single device according to an embodiment of the invention can be located, for example, behind the degassing unit. The system can be set to sound an alarm if a large amount of air bubbles is detected in the slurry downstream of the degassing unit. This kind of production system with alarm can greatly reduce the use of expensive foaming agent, but it is necessary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com