Disposal screw thread forming numerically controlled grinder for mini milling cutter for printed circuit board

A printed circuit board and CNC grinding machine technology, which is applied to milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of many processes, long production process time, high scrap rate, etc., and achieve high product qualification rate, save production time, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

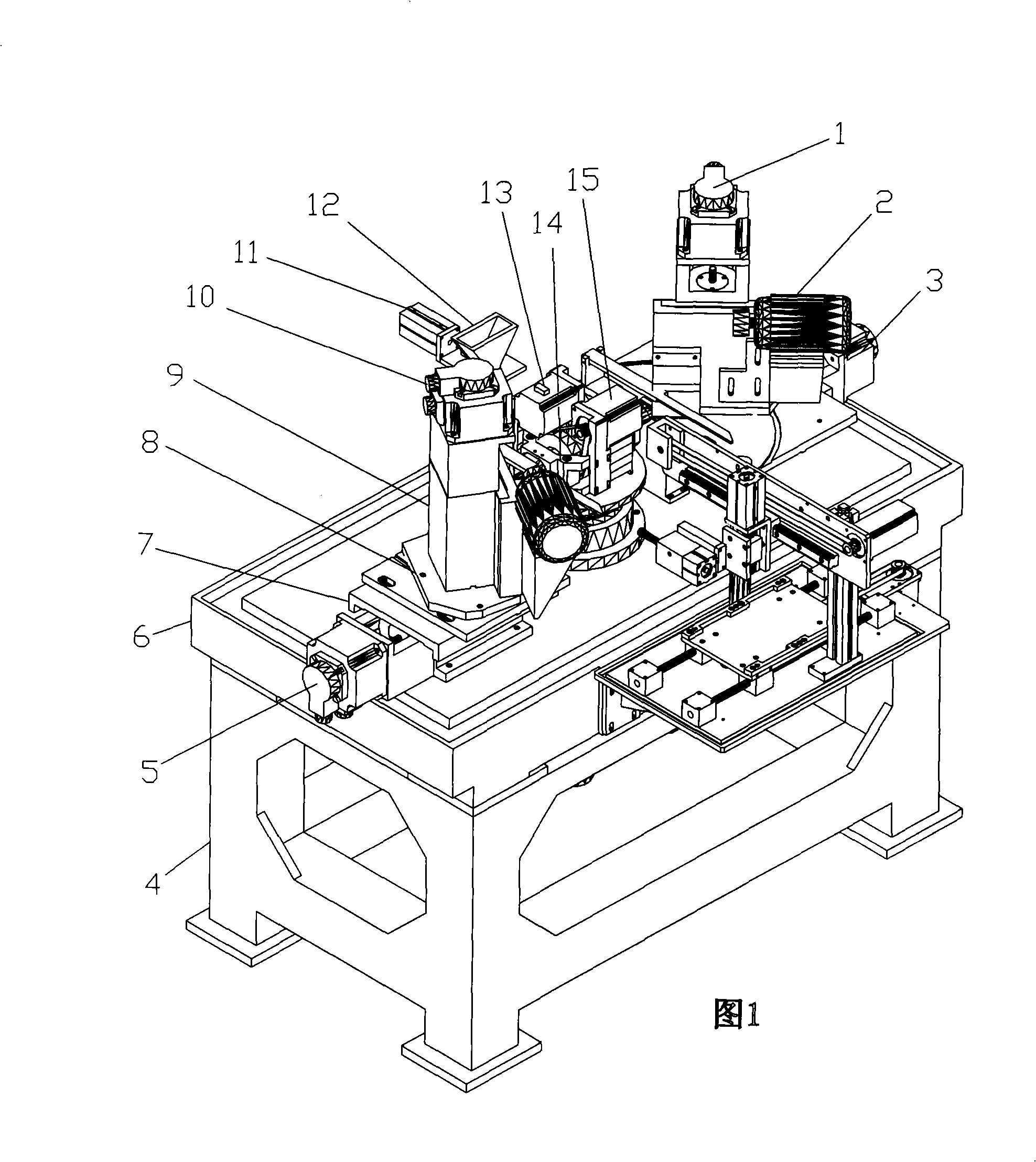

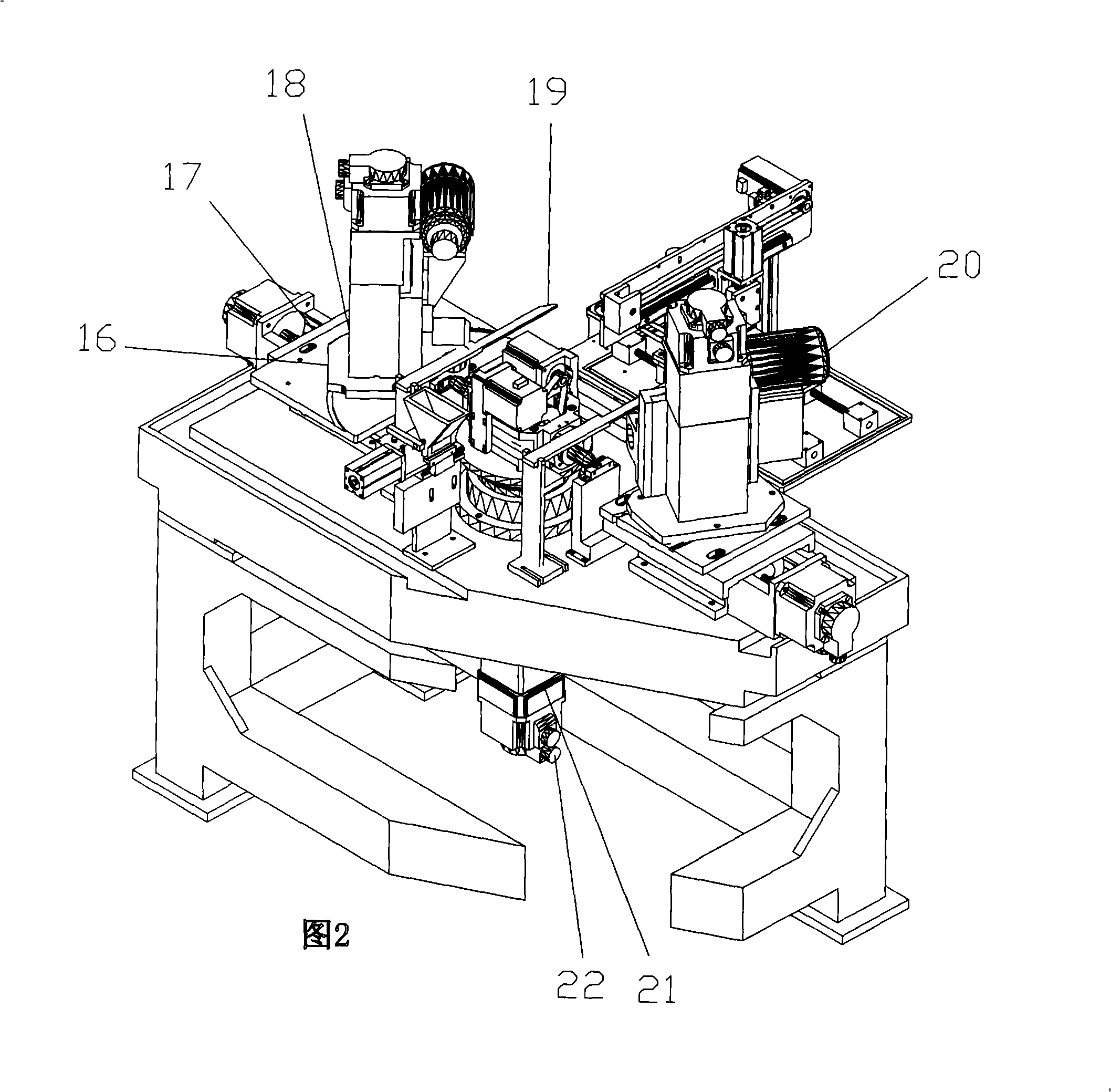

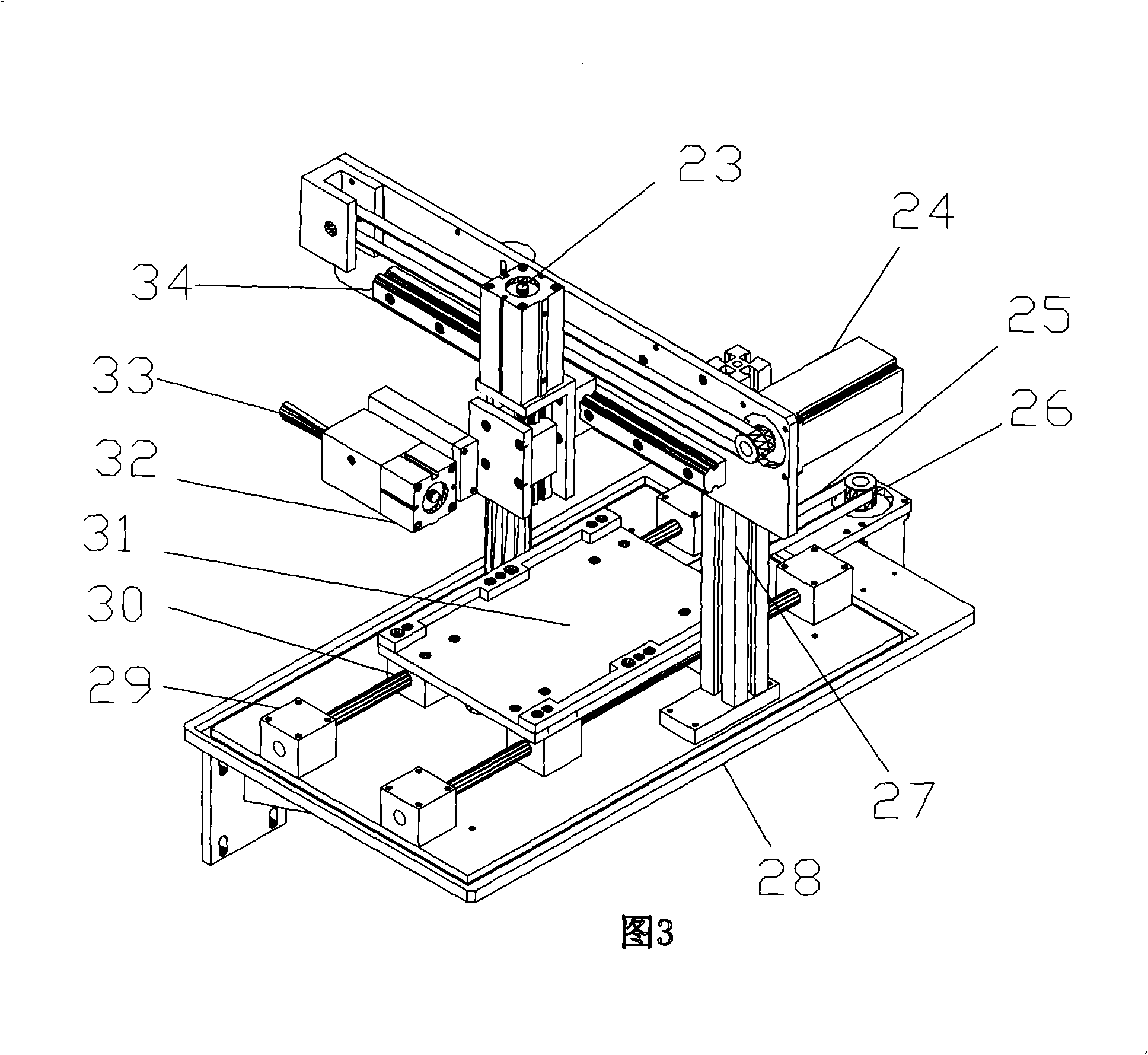

[0025] The printed circuit board micro-milling cutter disposable thread forming numerical control grinder provided by the present invention has a structure as shown in Figs. 1 to 3: including feeding, thread grinding, feeding mechanism and worktable conversion shaft. The thread grinding mechanism is composed of a left-handed thread grinding and a right-handed thread grinding mechanism. When the micro milling cutter is processed, a table conversion axis is used to automatically switch the grinding work of the left-hand thread and the right-hand thread, and press the numerical control grinder With the NC program in the memory, the manipulator will automatically place the milled cutters on the designated material tray in the order of work.

[0026] The left-handed thread grinding mechanism is mainly composed of X1-axis linear slide, Y1-axis linear slide, left-hand angle adjustment plate, grinding spindle, diamond grinding wheel, X1-axis linear slide and Y1-axis linear slide are each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com