Crude oil electric desalting test device

A test device and electric desalination technology, applied in the field of crude oil electric desalination test device, can solve the problems of large deviation of test data and production data, lack of guiding significance in production and research, and only static test can be carried out, so as to achieve less time spent and improved Accuracy and reliability, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

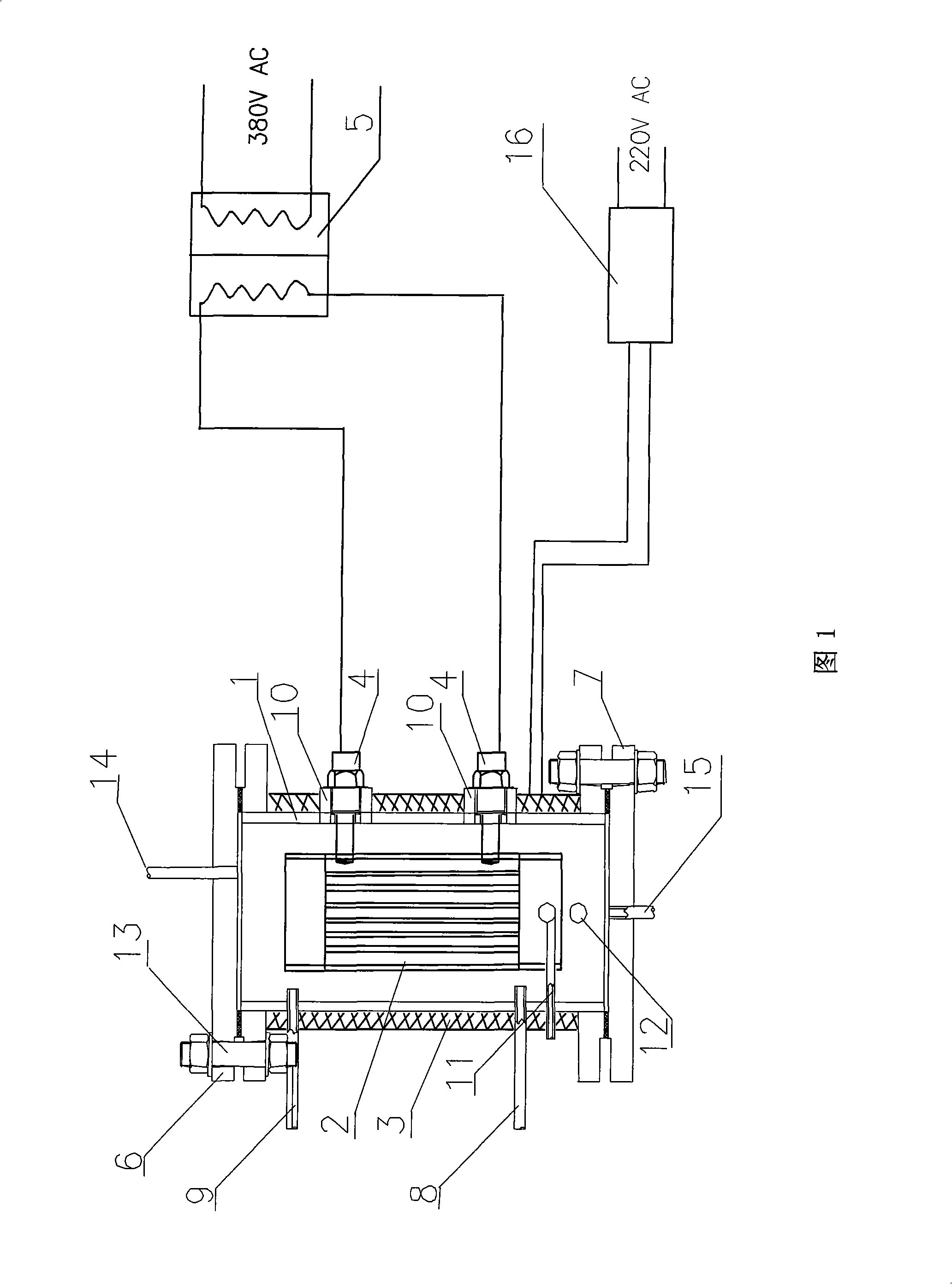

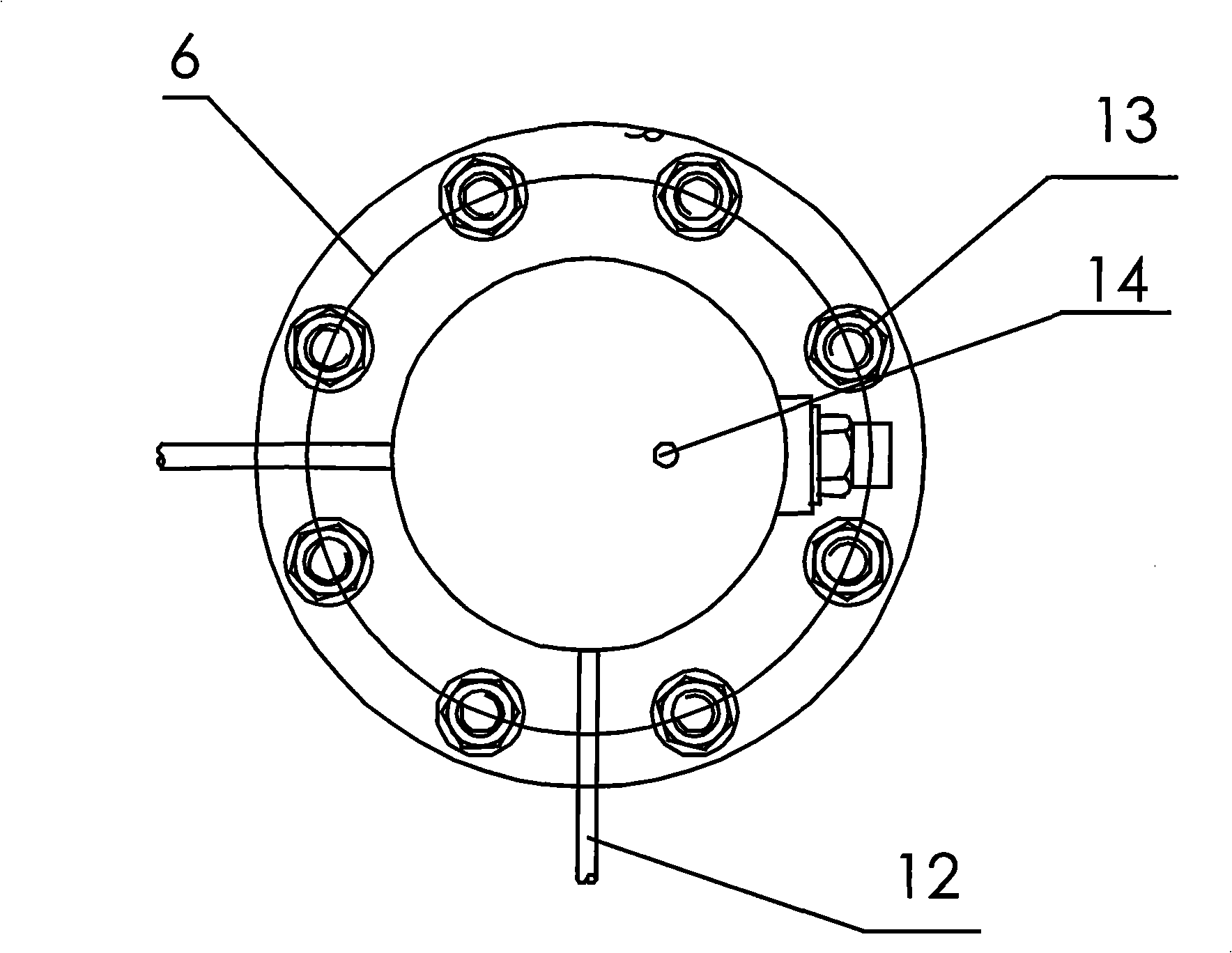

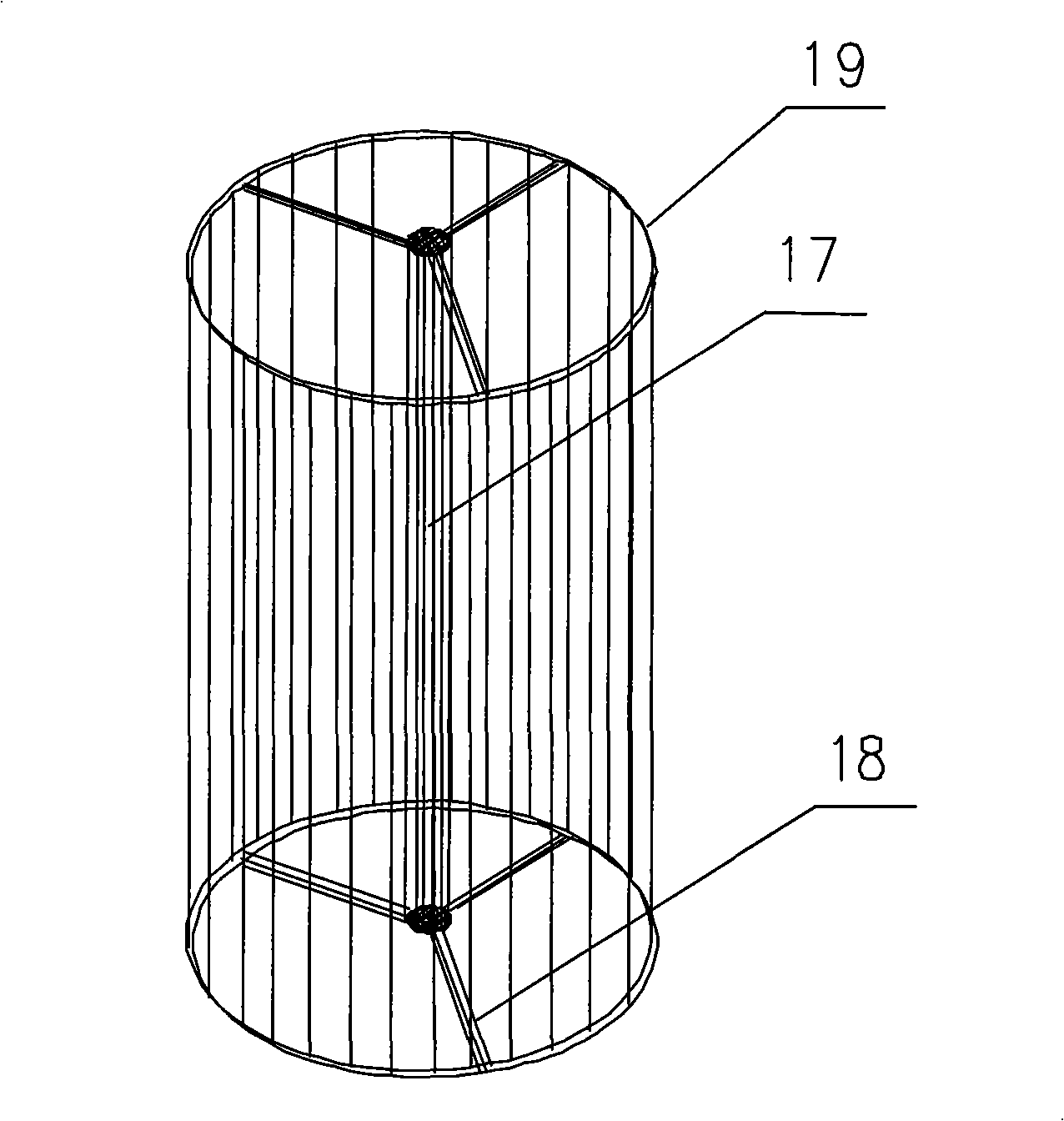

[0010] The present invention has a tank body 1. The inside of the tank body 1 is equipped with an overall cylindrical electrode grid 2, and the outside is equipped with a temperature-controllable electric heating jacket 3. There is an upper sealing flange 6 on the top of the tank body 1, and a lower sealing method on the bottom. Lan 7, there are crude oil inlet pipe 8 and crude oil outlet pipe 9 on the left lower part and left upper part of the tank body 1 respectively, and there are two high-voltage electric inlets 10 on the right part, and a thermometer 11 is inserted into the tank body 1 through the insertion port, and the tank body 1 There is an observation sampling 12 at the front lower part of the tank, and the sample in the tank body 1 can be observed for analysis and control without interrupting the test process. The upper sealing flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com