Vibrator material for mobile phone vibrating motor and preparation

A vibration motor and vibrator technology, applied in the field of mobile phone parts, can solve the problems of large volume, high cost, imperfect alloy composition and process method of the vibration motor, and achieve high production efficiency, good vibration quality, anti-corrosion and anti-oxidation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

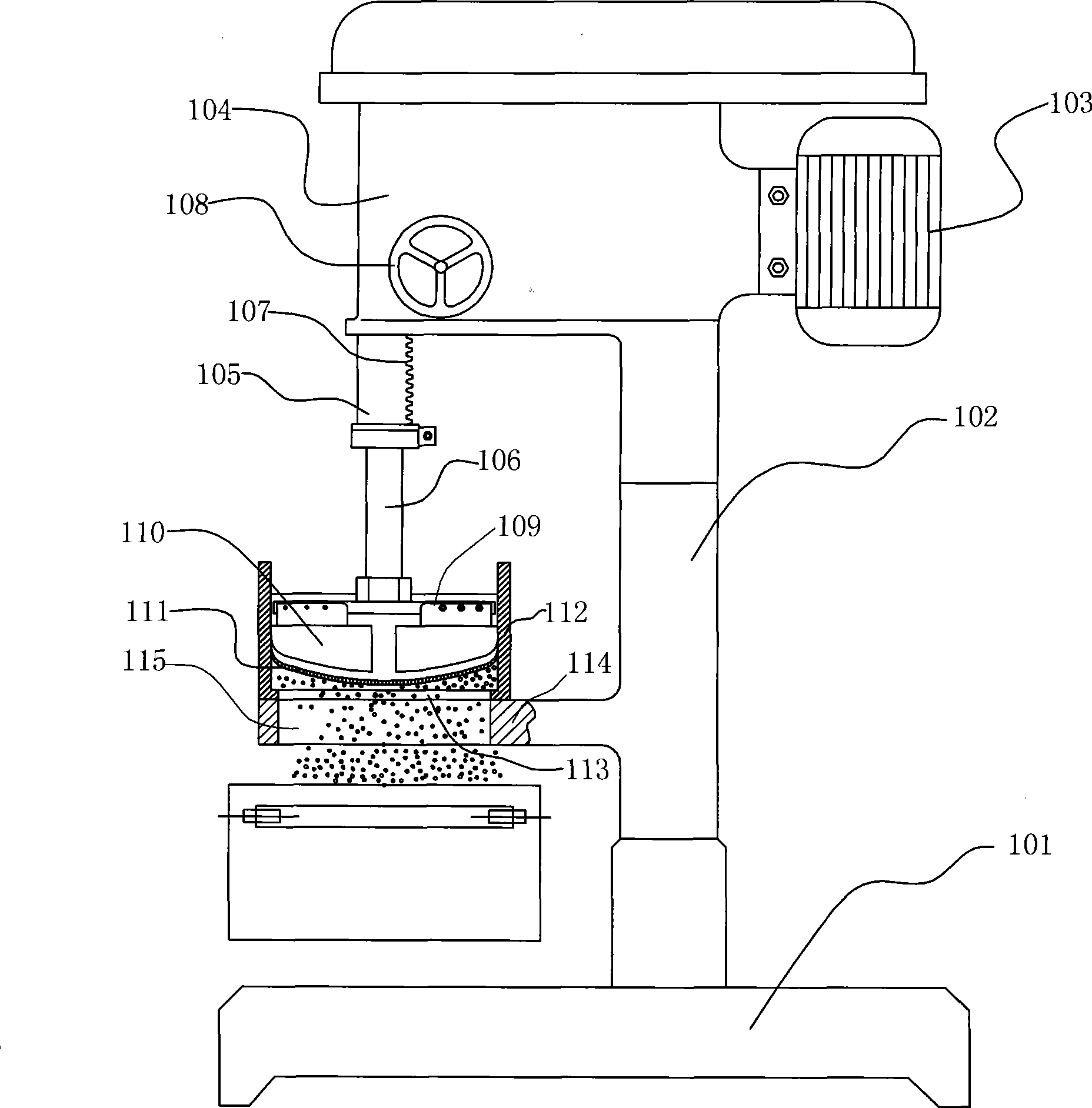

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] The vibrator material for mobile phone vibration motor is a high specific gravity tungsten-nickel-copper alloy, wherein the content of tungsten is 95-97wt%, the content of nickel is 2-3wt%, the content of copper is 1-2wt%, and the tungsten-nickel - The total purity of the copper alloy is > 99.9 wt%. The vibrator prepared by the high specific gravity tungsten alloy has the characteristics of high strength and high hardness, small expansion coefficient, good corrosion resistance and oxidation resistance, good vibration quality, high operation stability and long service life.

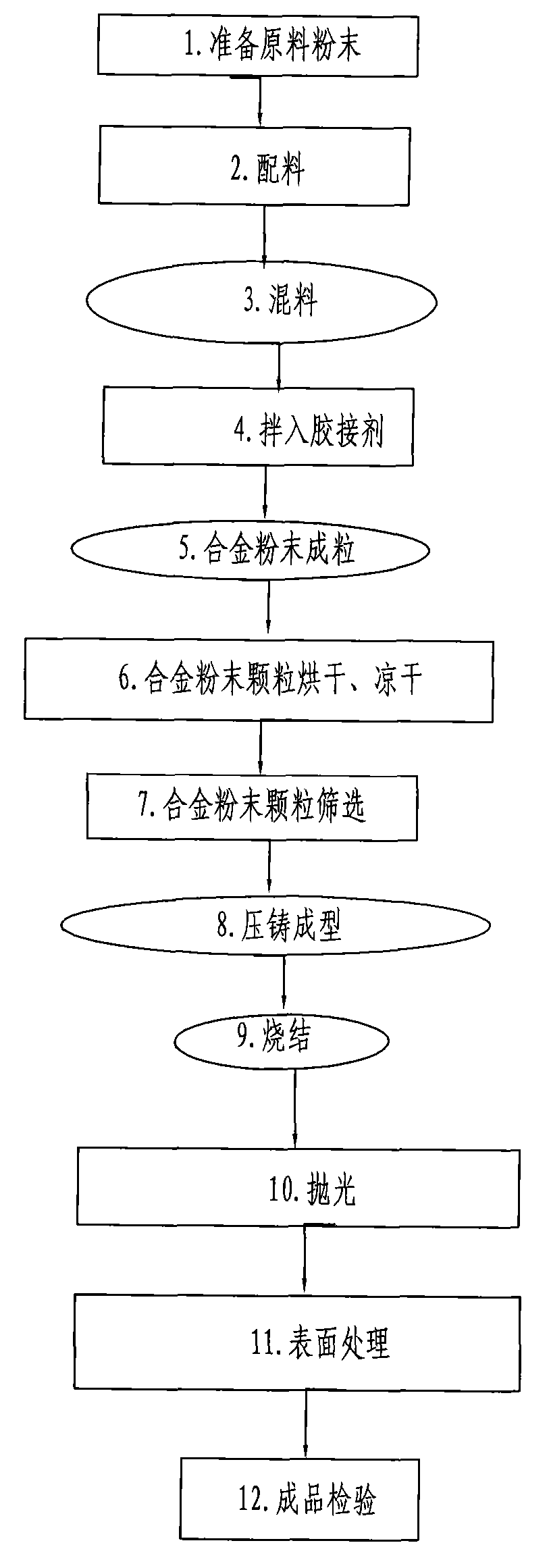

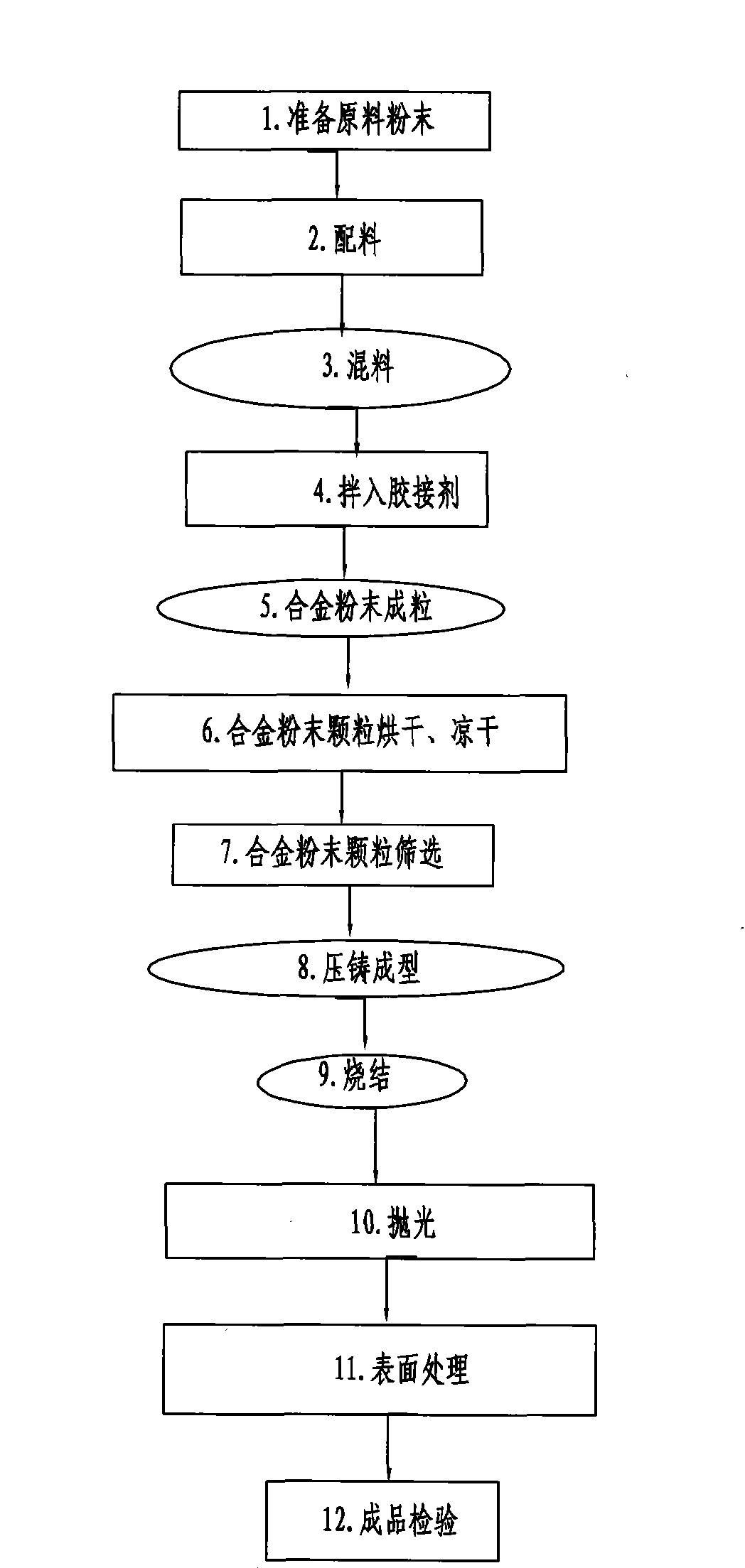

[0026] As shown in Figure 1, the preparation method of using the above-mentioned high specific gravity tungsten alloy to prepare a vibrator for a mobile phone vibration motor is as follows:

[0027] ① Prepare the metal powder raw materials used in the vibrator acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com