Method for manufacturing rotor portion of motor integrated type pump and motor integrated type pump equipped with the rotor portion

A manufacturing method and integrated technology, which are applied to components of pumping devices for elastic fluids, manufacturing stator/rotor bodies, non-variable-capacity pumps, etc., can solve problems such as magnet deterioration, improve productivity, improve The effect of production performance, easy arrangement and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

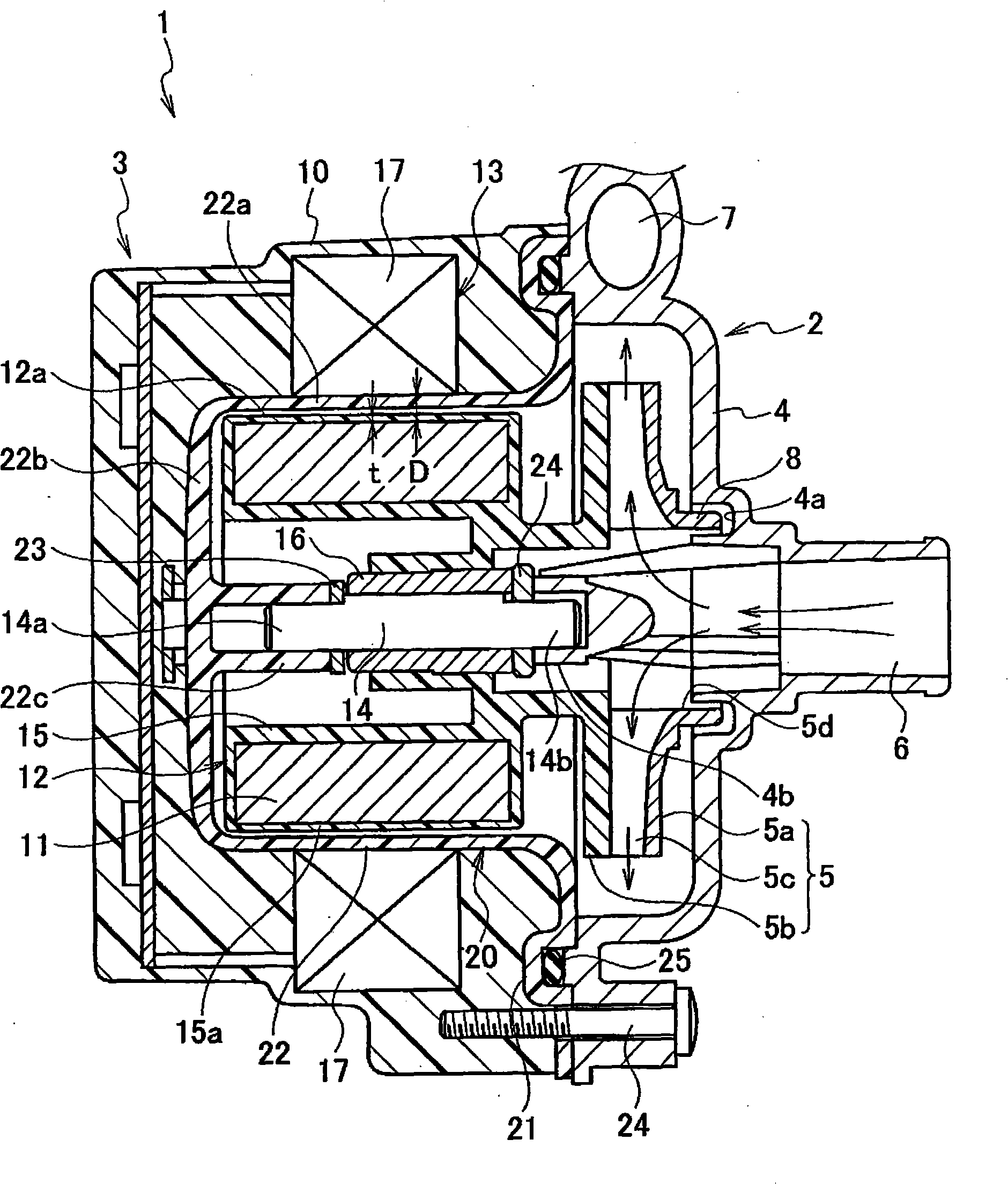

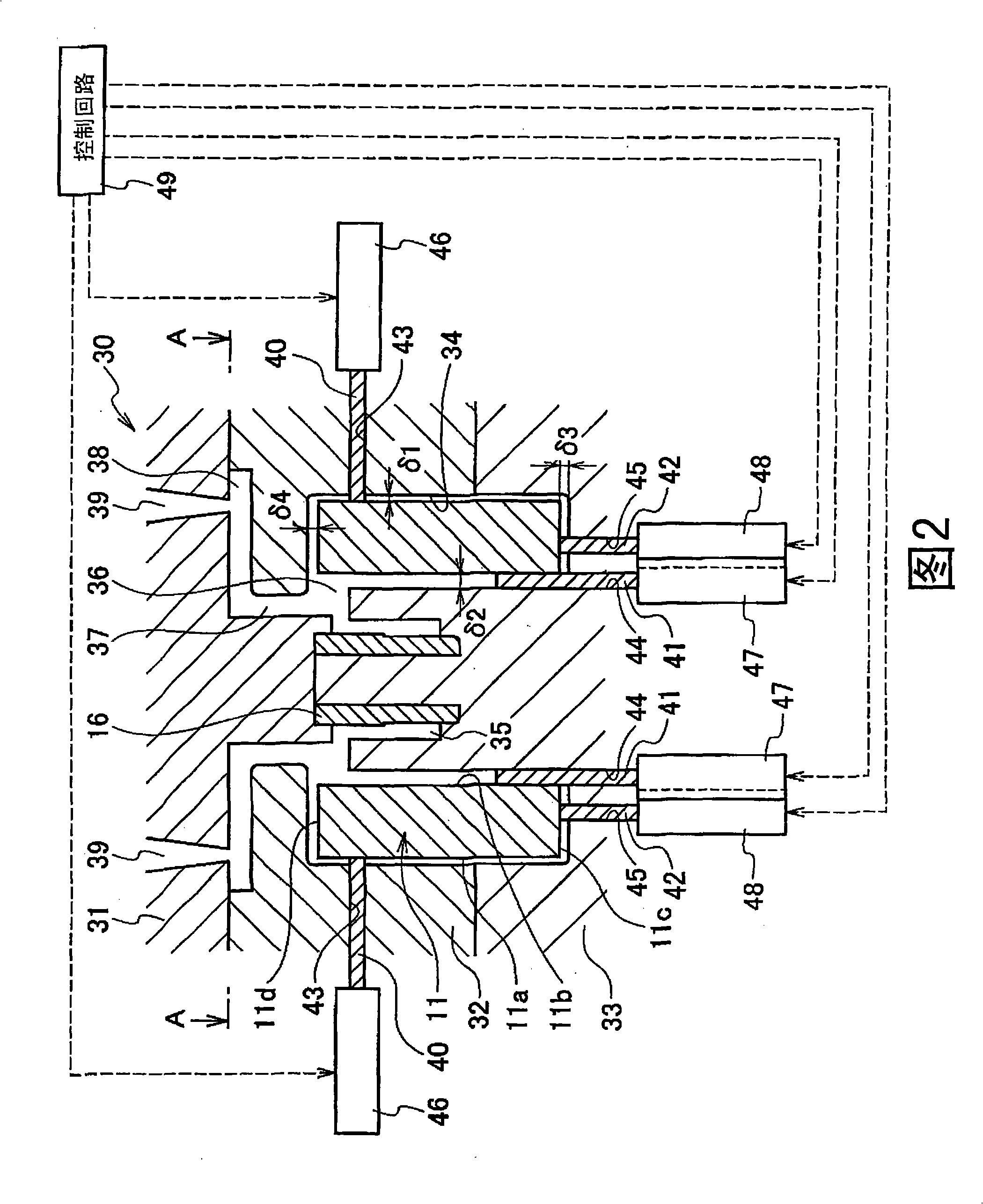

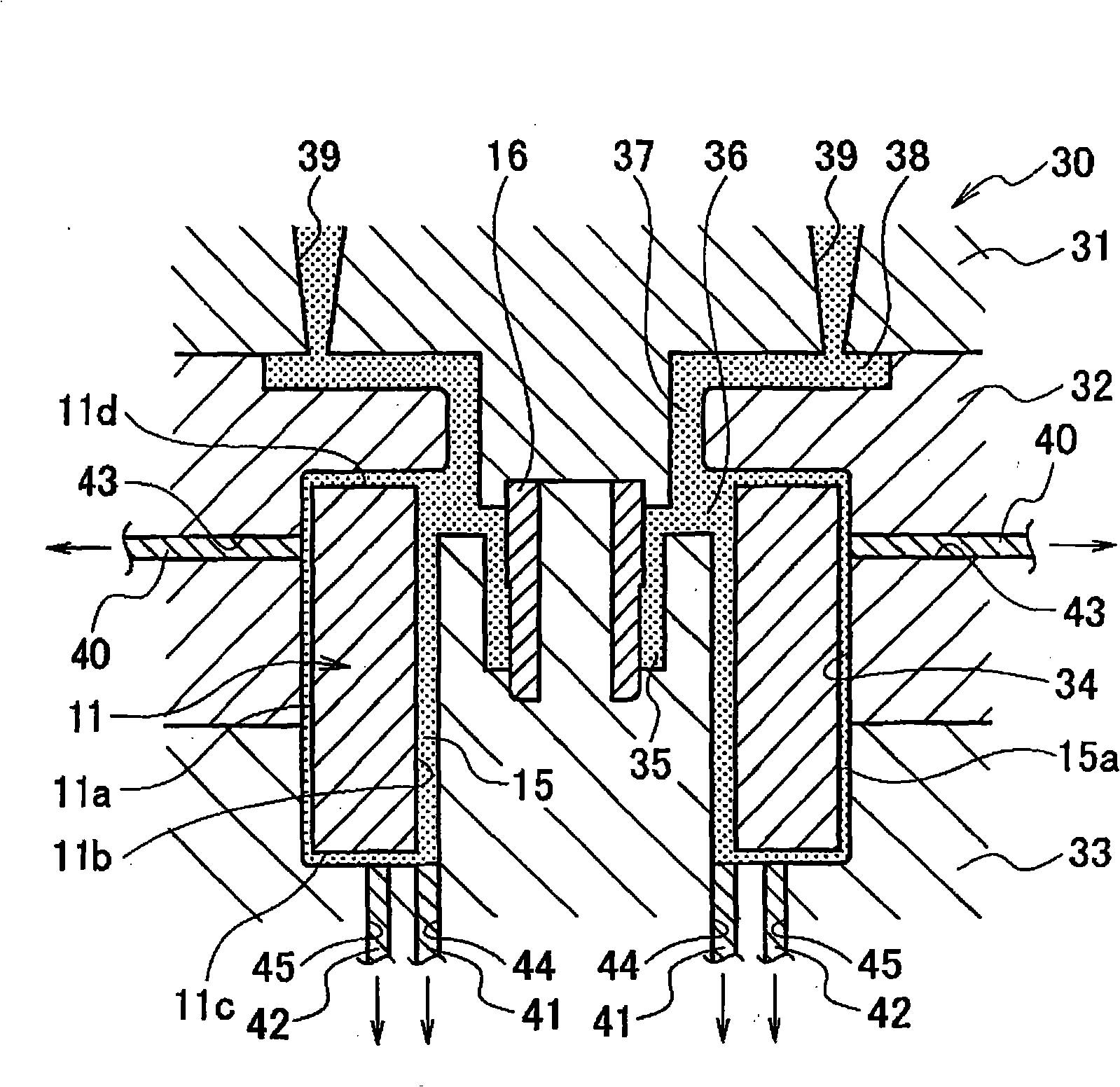

[0035] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. Figure 1 ~ Figure 4 The motor-integrated pump of this embodiment is shown. in, figure 1 Fig. 2 is a cross-sectional view of a motor-integrated pump, and Fig. 2 is a cross-sectional view of a mold in the initial stage of manufacturing a rotor part of a motor-integrated pump, image 3 It is a cross-sectional view of a mold in the final stage of manufacturing the rotor part of a motor-integrated pump, Figure 4 It is a sectional view taken along line A-A in FIG. 2 .

[0036] Such as figure 1 As shown, a motor-integrated pump (hereinafter simply referred to as a pump) 1 of this embodiment is formed by integrally combining a pump unit 2 arranged on the right side in the figure and a motor unit 3 arranged on the left side in the figure.

[0037] The pump unit 2 is accommodated in the pump housing 4, and includes: a scroll impeller 5; a suction port 6 for sucking a workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com