Embedded type common basal plane two-dimension balance double-drive double-workpiece platform positioning system

A technology of double workpiece table and positioning system, which is applied in the direction of photo-plate-making process of pattern surface, photo-plate-making process exposure device, optics, etc., can solve the problems of poor structural rigidity, low reliability, and many error links, so as to avoid Vibration and instability, avoiding more complex structures, and the effect of a simple reference plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

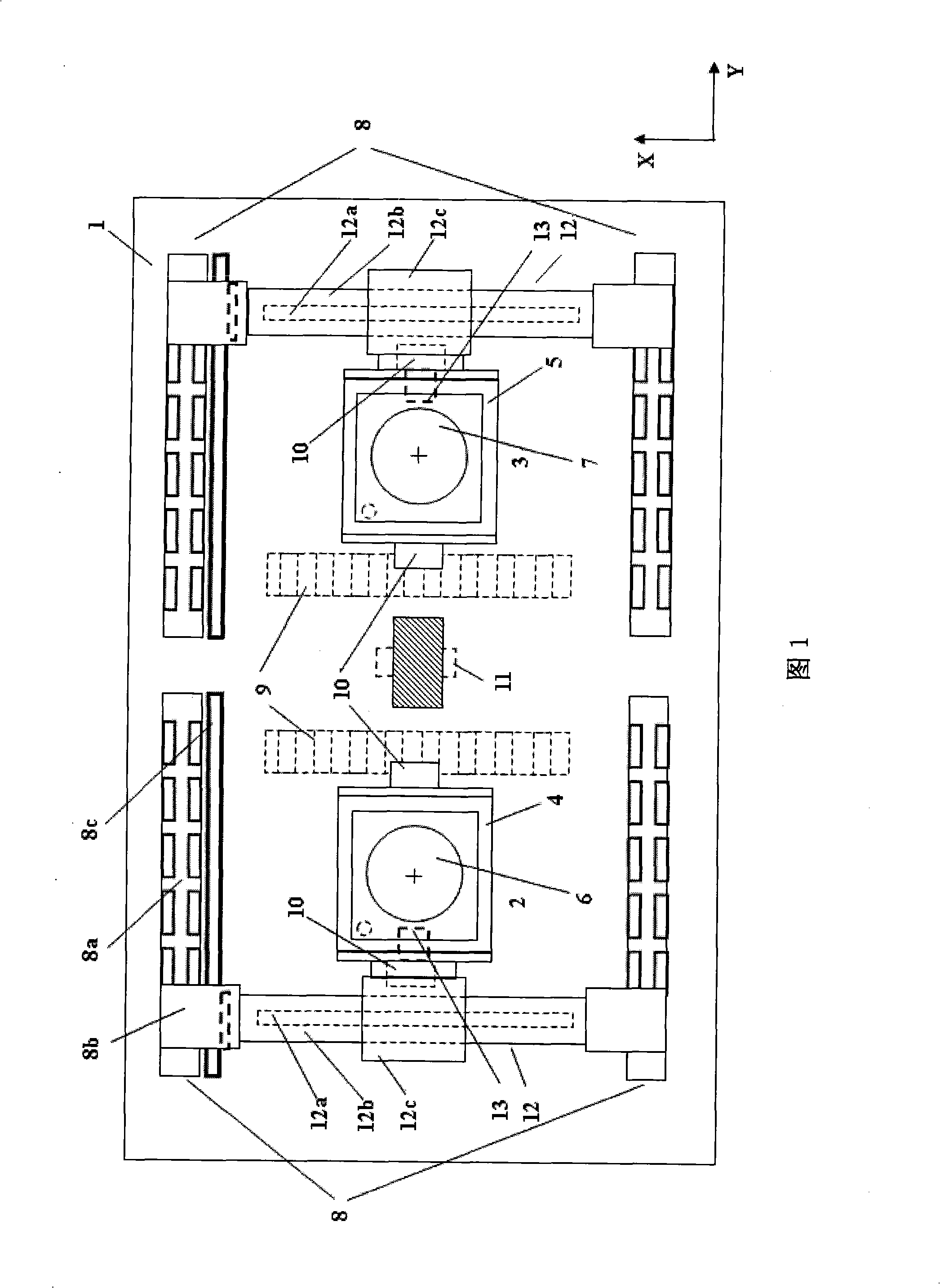

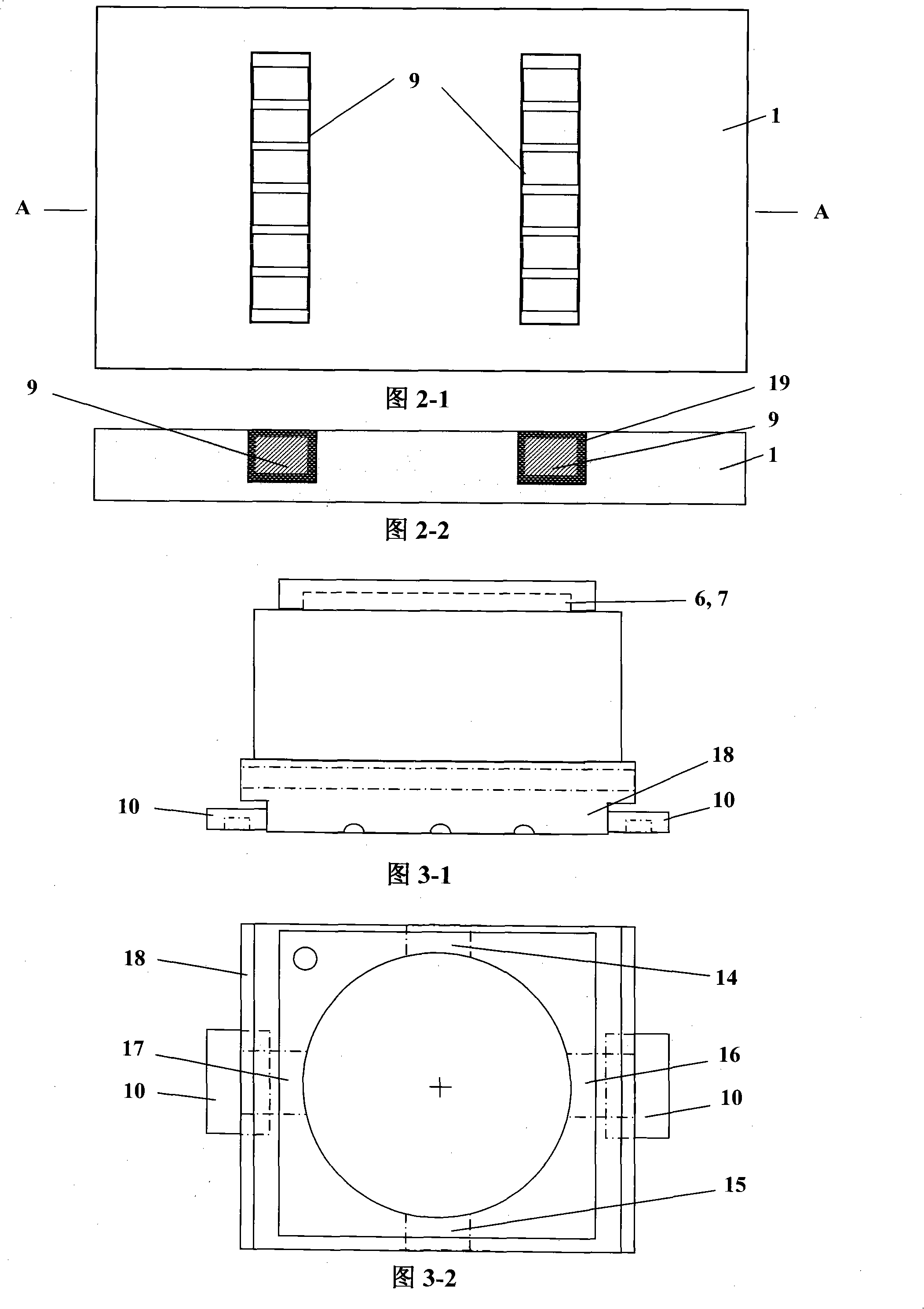

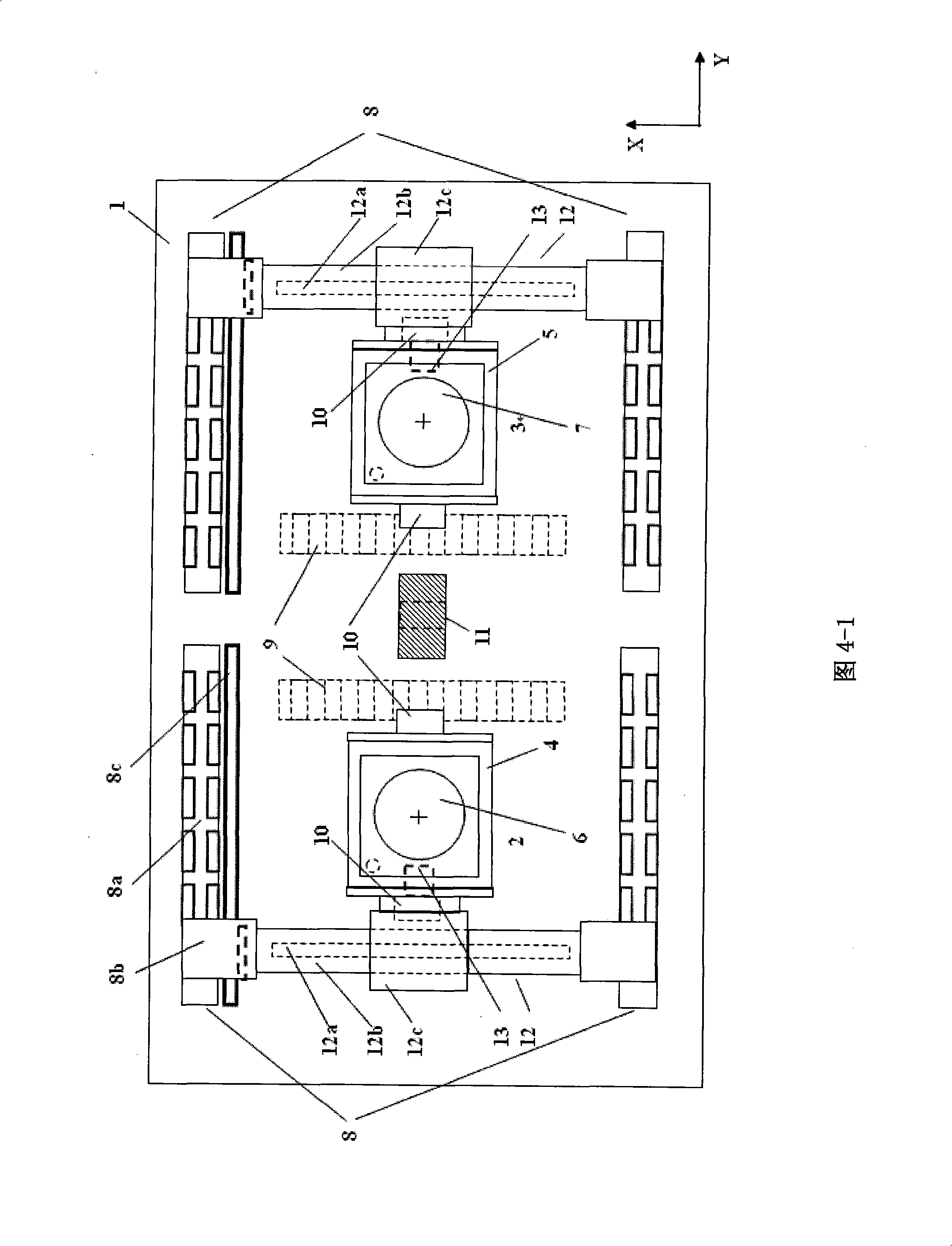

[0023] As shown in Figure 1, an embedded two-dimensional balanced dual-drive dual-workpiece positioning system with a common base includes a base 1, a workpiece A4, a workpiece B5, a wafer A6, a wafer B7, and a U-shaped groove. Two pairs of Y-direction double-sided synchronous linear motor units 8 composed of linear motor 8a, air bearing guide rail bushing 8b, and Y-direction guide surface 8c, two X-direction single-plate linear motor movers 10, cross-shaped positioning lap mechanism 11, Two X-direction single-side linear motor units 12 composed of U-shaped groove linear motor 12a, air-floating guide rail 12b, and air-floating bushing 12c, telescopic guide rod 13, workpiece table positioning notch A14, and workpiece table positioning notch B15 , the workpiece table positioning notch C16, the workpiece table positioning notch D17 and the air bearing 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com