Method for welding rocking arc narrow clearance melting electrode with gas protection and welding torch

A technology of molten electrode gas and shielded welding, which is applied in the direction of arc welding equipment, welding equipment, electrode support devices, etc., can solve the problems of increased welding cost, large wear of the contact tip, and low service life, and achieves reduced welding cost and high welding quality , long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

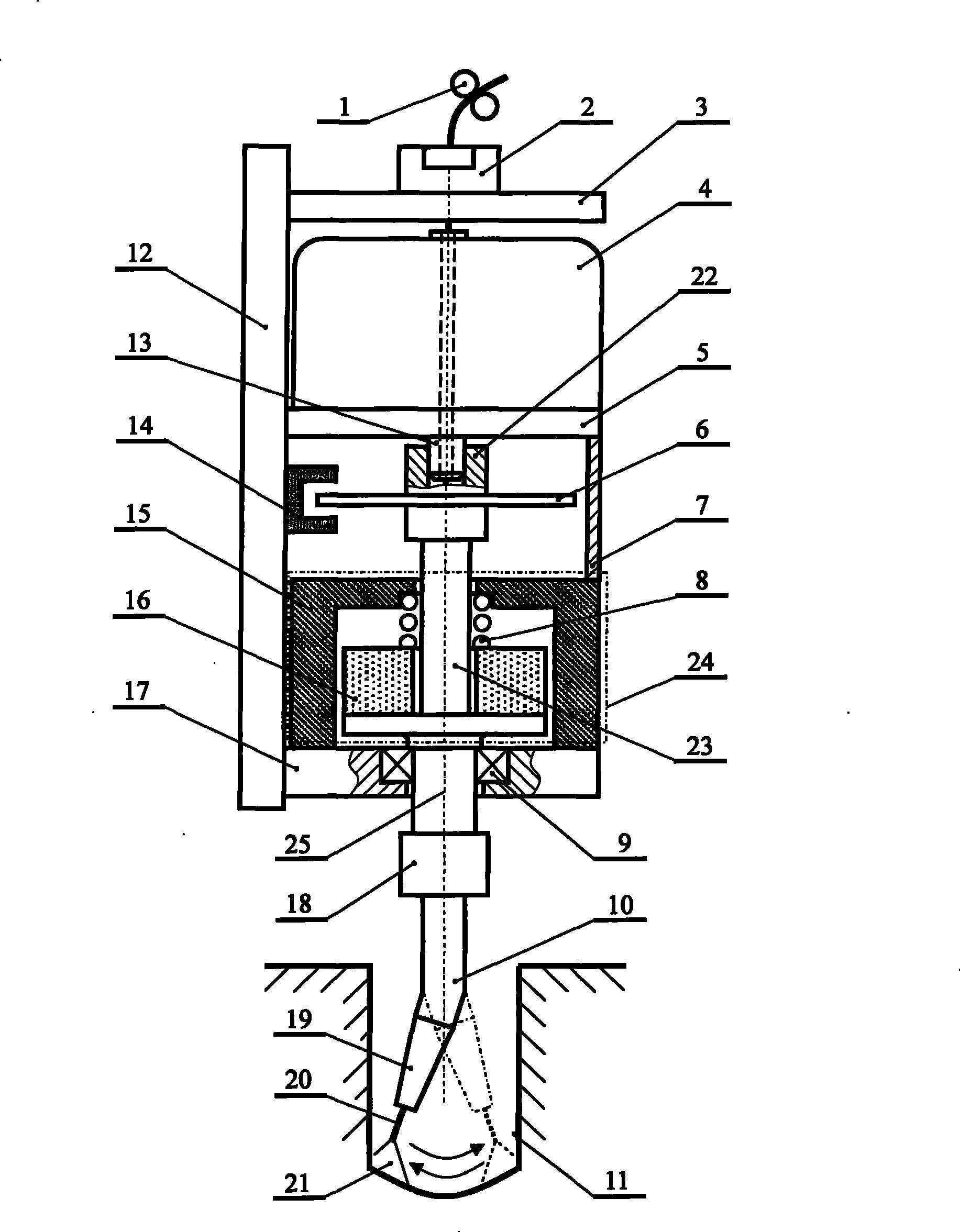

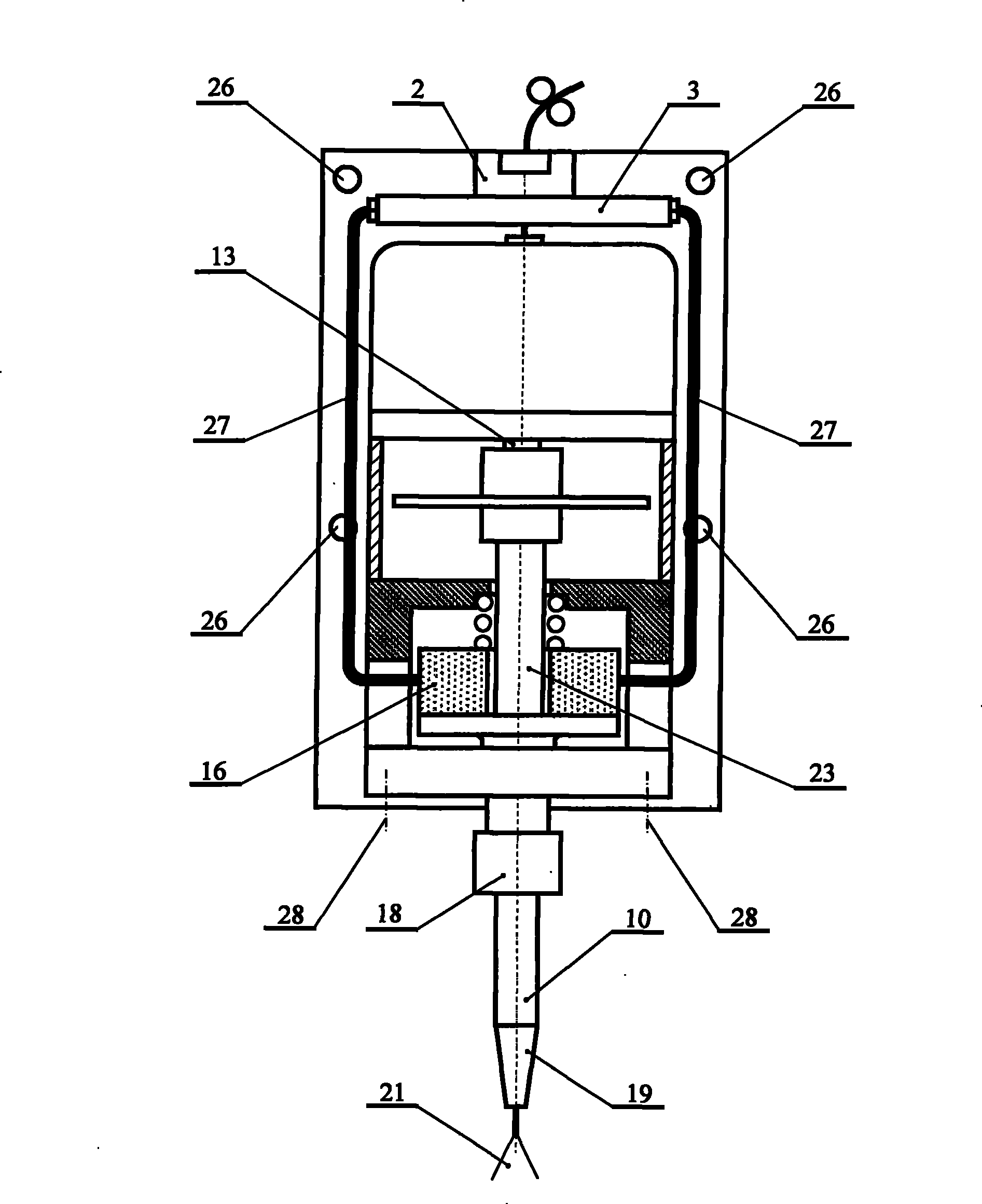

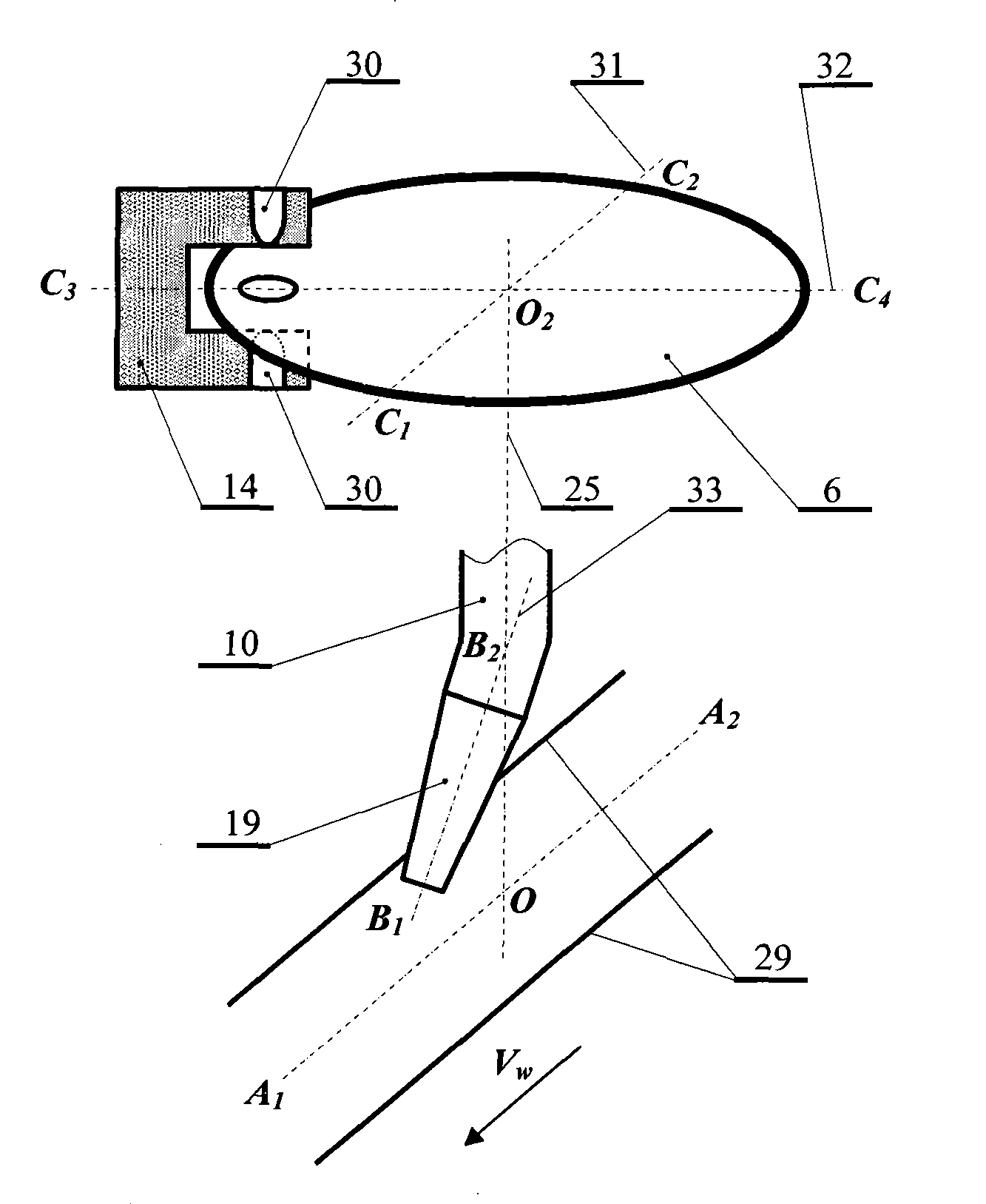

[0022] Such as figure 1 , 2 As shown, the welding wire 20 sent by the wire feed roller 1 penetrates through the central hole of the coupling head 2, passes through the central hole of the coupling head support 3, the hollow shaft of the motor 13, the coupling 22, the straight conductive rod 23, and the connecting piece 18. After the central hole of the slightly bent conductive rod 10 , pass through the central hole of the conductive tip 19 to generate a welding arc 21 at the groove 11 of the workpiece. It adopts the general-purpose gas shielded welding machine cable connection head 2, so that the welding torch can be conveniently connected with the feeder cable of the general-purpose welding machine. The hollow shaft motor 4 is installed on the motor support 5 , and the lower end of the motor hollow shaft 13 passes through the motor support 5 and is connected with the coupling 22 . The connecting cable 27 is fixedly connected to the brush mechanism 24 and the coupling head 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com