High-strength low-chromium anti-corrosion petroleum pipe special for low CO2 environment

A special oil pipe and high-strength technology, which is applied in the field of high-strength, low-chromium, anti-corrosion oil special pipes, can solve the problems of increasing smelting cost and difficulty, and achieve the effect of reducing strength and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

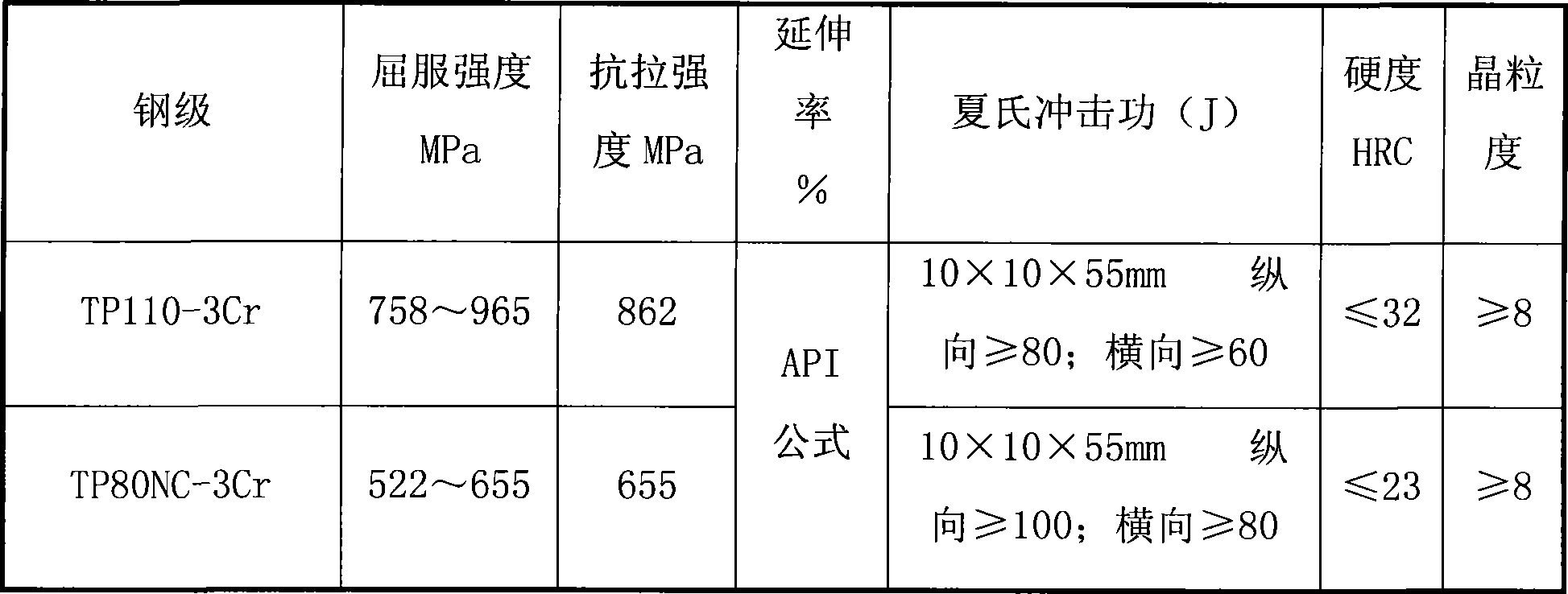

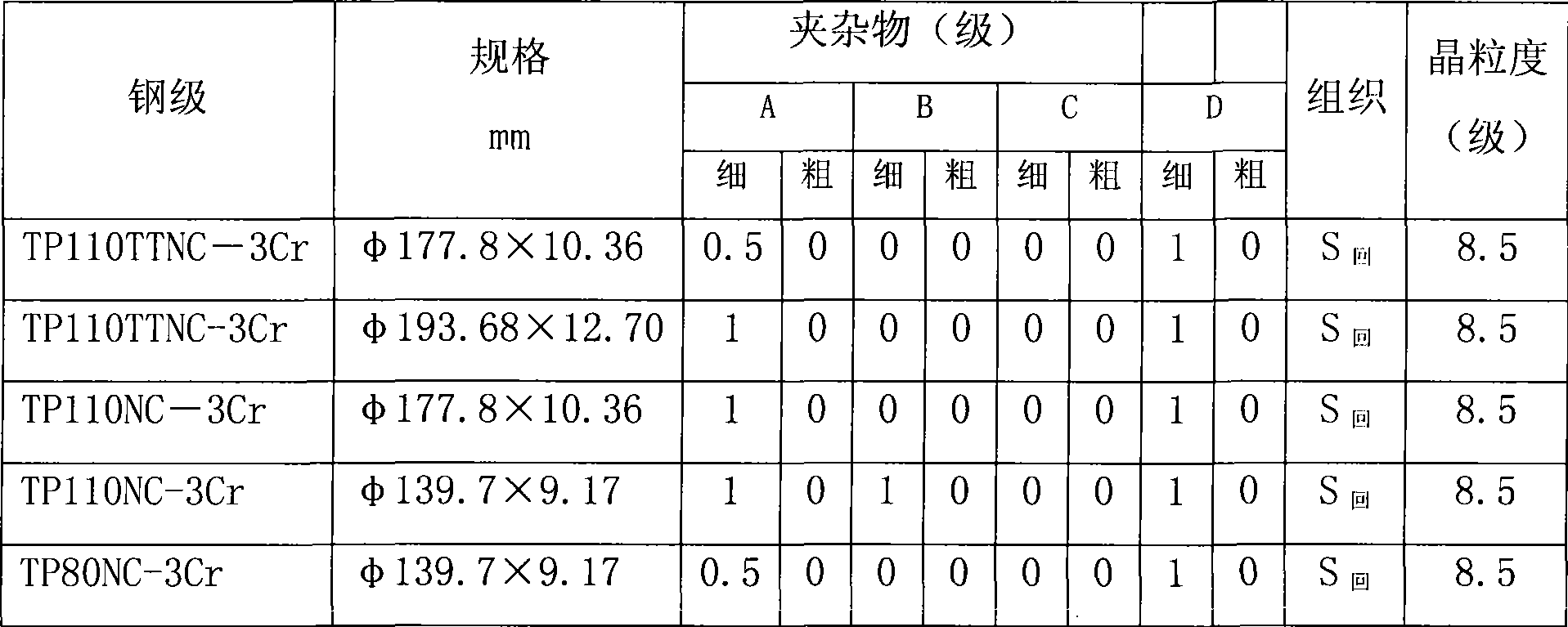

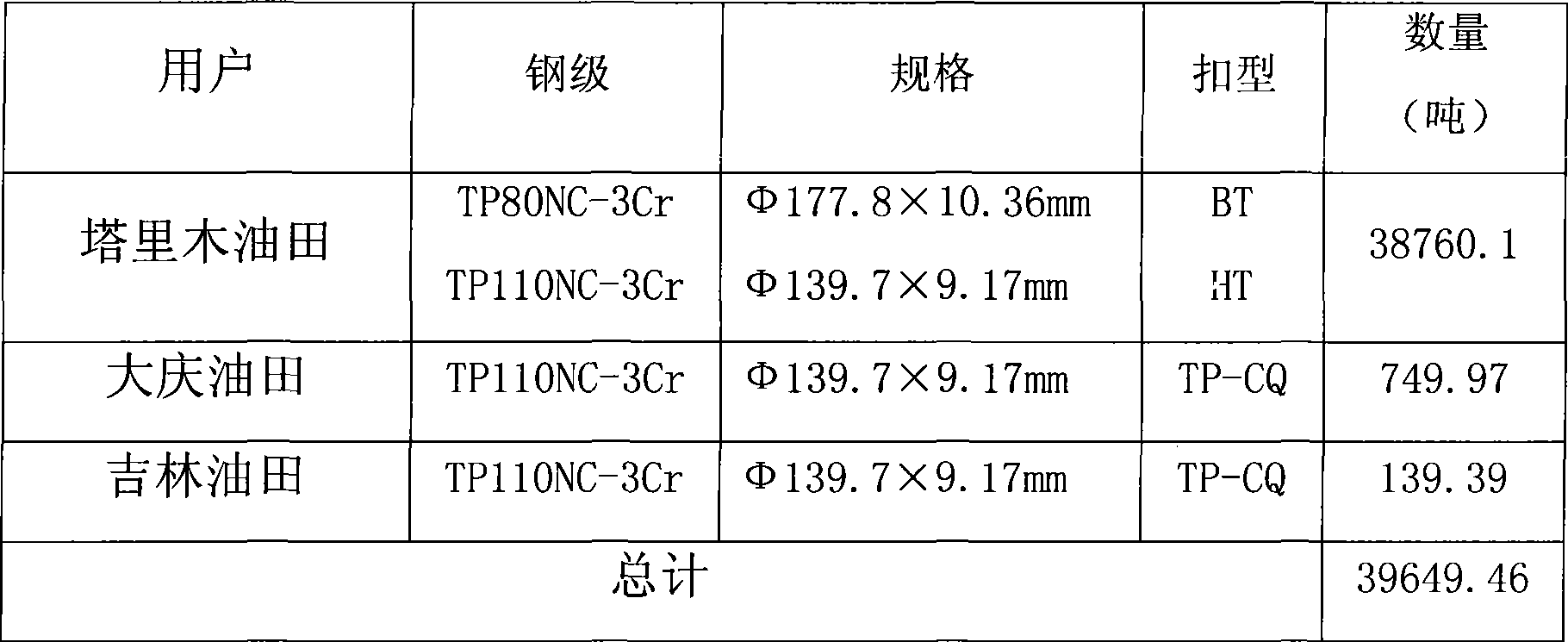

Examples

Embodiment Construction

[0010] In conjunction with embodiment low CO of the present invention 2 The environment is described with high-strength low-chromium corrosion-resistant special pipes.

[0011] Theoretical description of the chemical composition design of the low-chromium anti-corrosion special pipe of the present invention:

[0012] C: The amount of C added and the ratio of C to Cr and Mo will affect the carbide form of Cr and Mo, thereby affecting the sulfide stress cracking resistance of the steel pipe. In addition, the influence of carbon content on the strength and toughness of steel should also be considered Influence, comprehensive consideration, control the C content between 0.10% and 0.20%.

[0013] Si: Si is an element necessary for deoxidation and can also increase the strength of steel, but adding a large amount of silicon will reduce toughness and corrosion resistance, so its content is limited within the range of 0.15 to 0.45%.

[0014] Mn: Mn is a necessary element in steelmak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com