Friction energy-dissipating type close rib composite wall board

A technology of composite wall panels and dense ribs, which is applied to walls, building components, and earthquake resistance, can solve the problems of filling materials that cannot meet the selection requirements of building materials, structural damage and damage, and insufficient consideration of changes in structural seismic performance, etc., to achieve the goal of making raw materials The effect of diversification, improvement of functions, and improvement of the overall earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

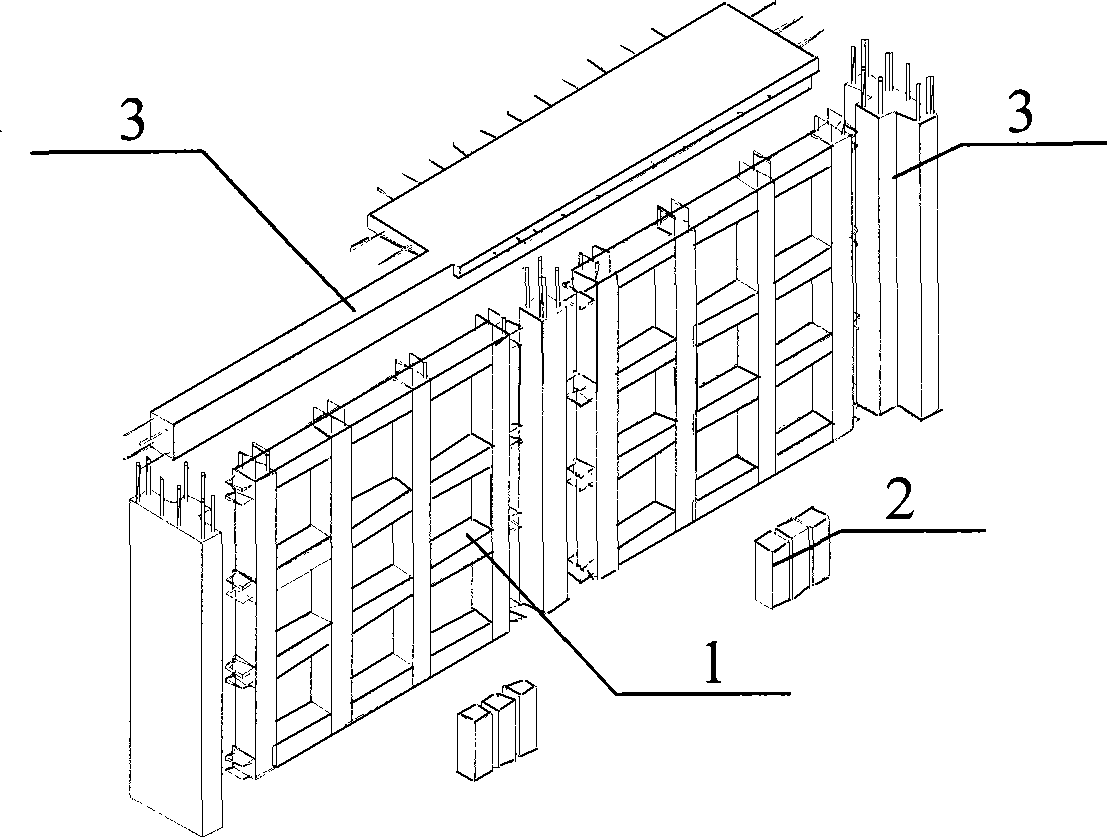

[0027] Embodiments of the invention will be described in further detail below in conjunction with the accompanying drawings.

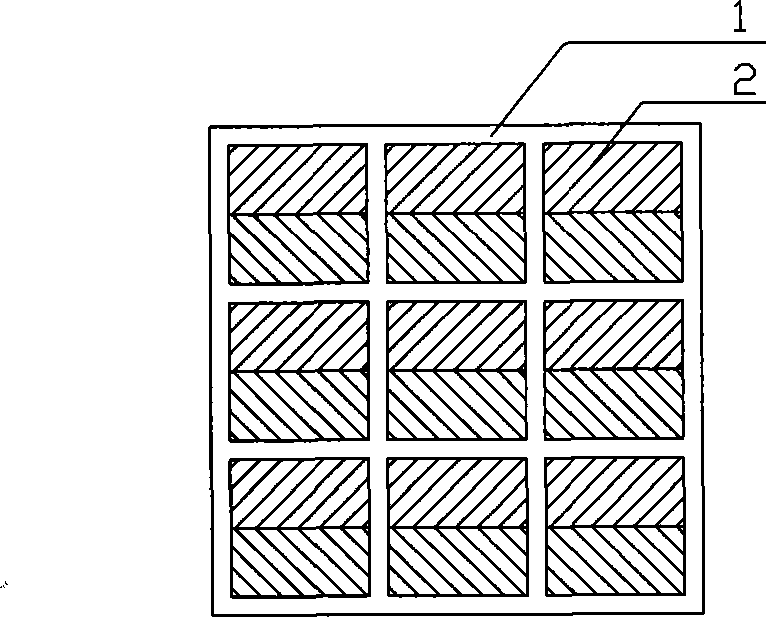

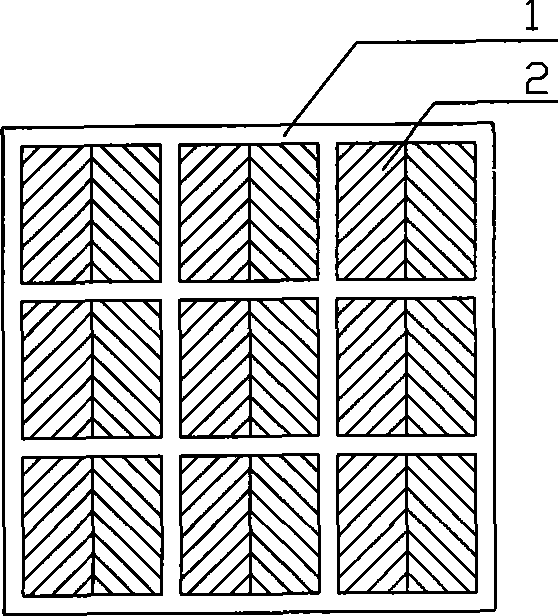

[0028] A densely ribbed composite wall panel used in a densely ribbed structure system, including a frame 3 composed of reinforced concrete beams and columns, the frame 3 is a grid cavity 1, according to the bearing capacity of the reinforced concrete beams, columns in the grid cavity Cavity 1 is correspondingly filled with more than two prefabricated blocks 2. The prefabricated blocks 2 are regular block energy-consuming parts made of industrial slag, fly ash, cement perlite, quartz sand particles, etc., and prefabricated The size of the blocks 2 is suitable for the size of the grid cavity 1 and there is a gap that allows the prefabricated blocks 2 to move between each other. In a uniform and sequential manner, the contact surfaces between adjacent prefabricated blocks 2 can overcome friction and relatively move.

[0029] Figure 2-7 shows different...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com