Tower rack type combined transmission oil pumping machine

A technology of combined transmission and pumping unit, which is applied in the direction of transmission, mechanical equipment, mining fluid, etc., can solve the problems of large meshing noise between gears, difficult manufacturing, oil leakage of reducer, etc., and achieves fewer failure points and low cost , good flood control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

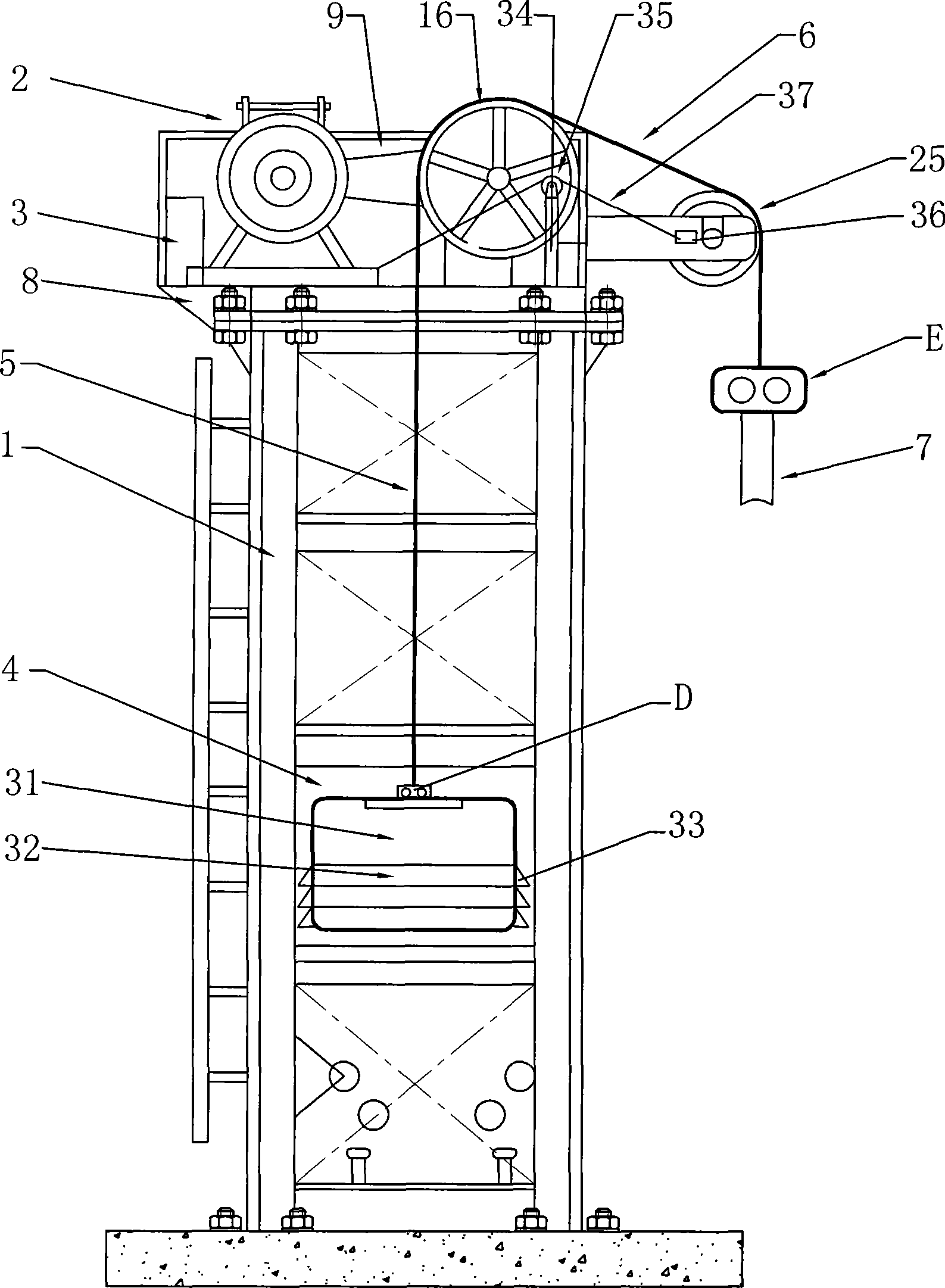

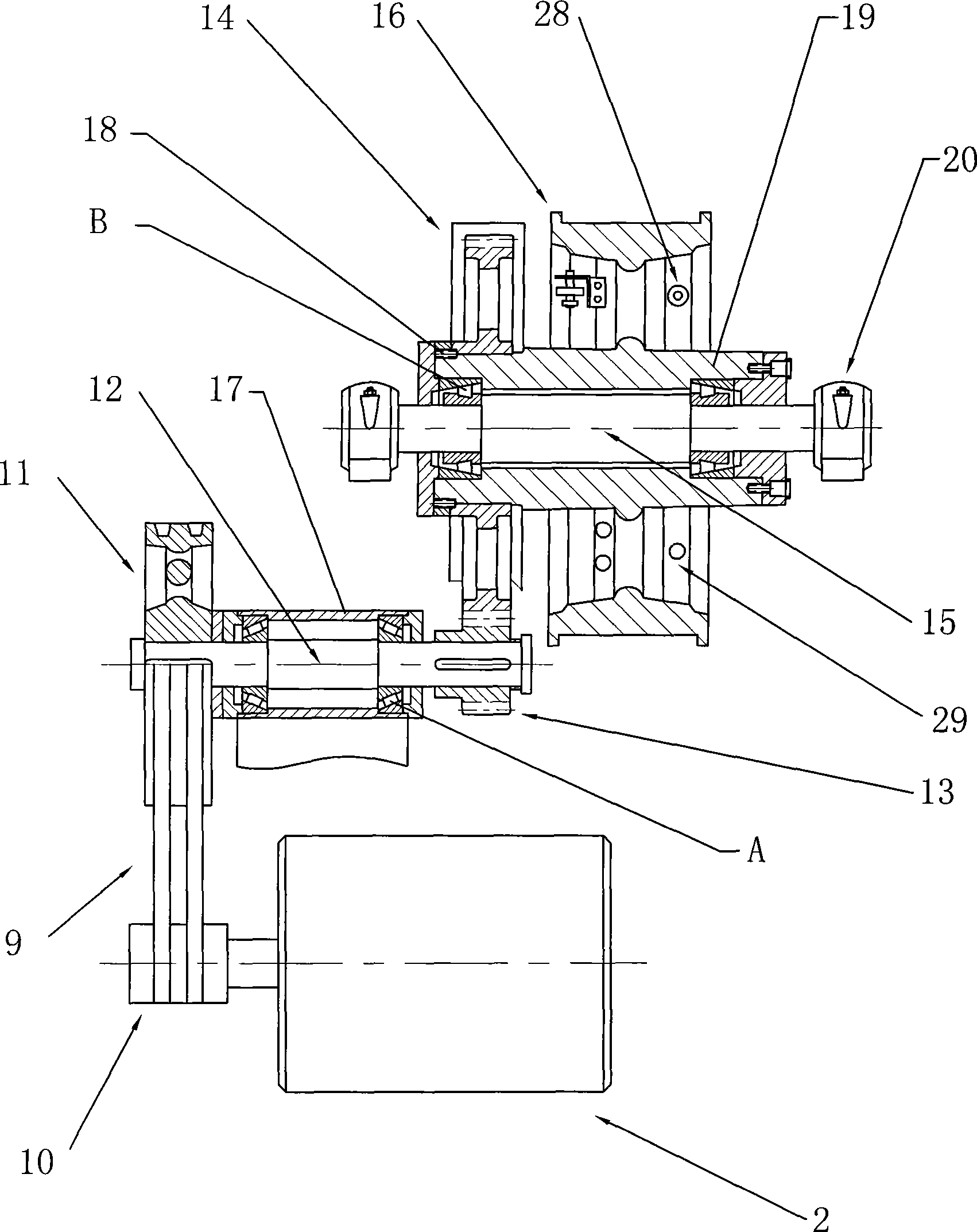

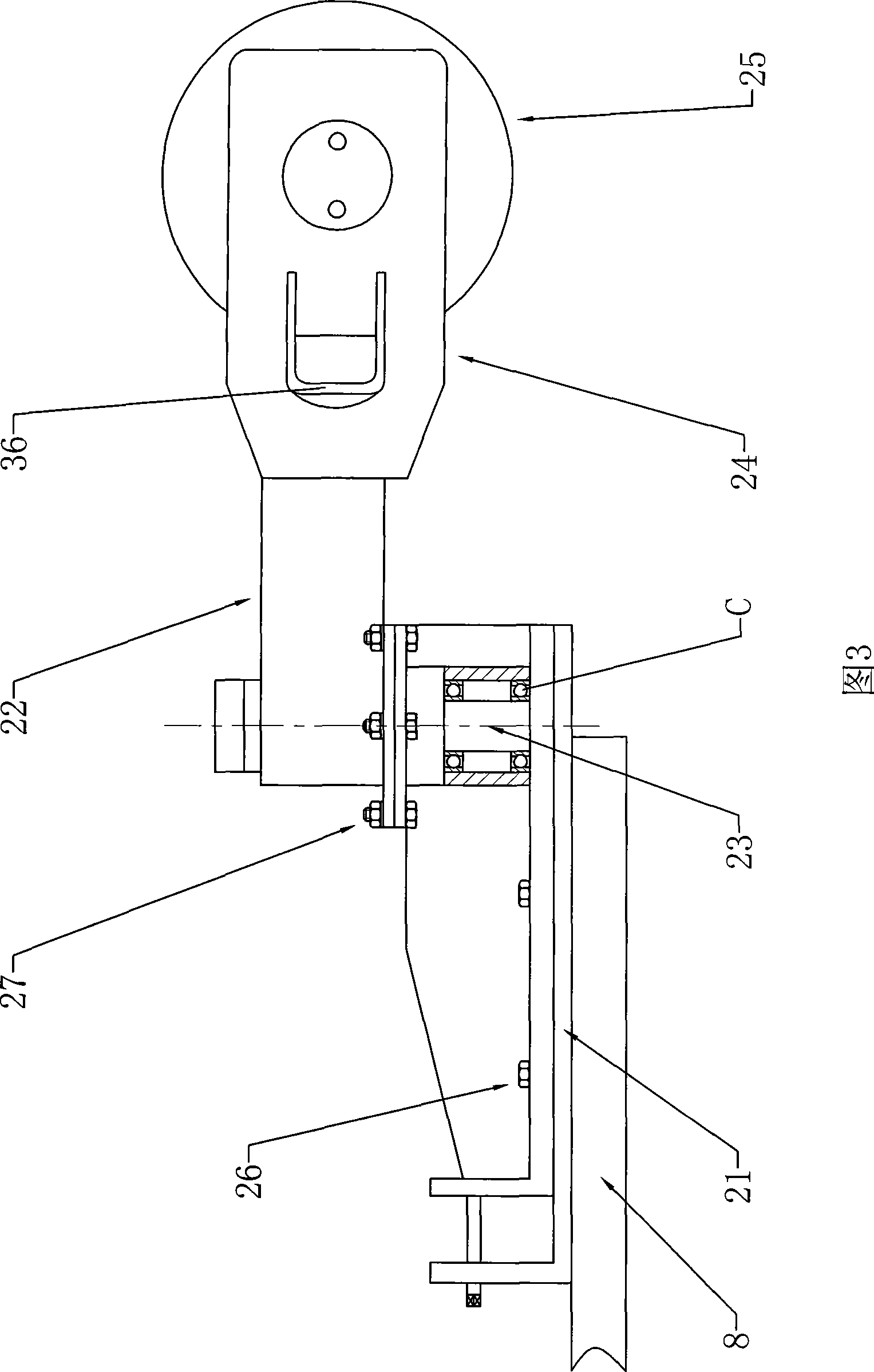

[0016] Such as figure 1 The tower type combined transmission pumping unit shown includes a tower 1, a power system 2, a transmission system, a control system 3, a balance counterweight box 4, a counterweight traction rope 5, a driving rope 6 and a rope hanger, wherein the power system 2. The transmission system and control system 3 are installed on the operating platform 8 at the top of the tower 1, and the staff can control the entire tower-type combined transmission pumping unit under the tower 1 through the wireless or wired controller of the control system 3. Control operation, balance counterweight box 4 is provided with main counterweight box 31 and auxiliary counterweight 32, and auxiliary counterweight 32 is articulated on main counterweight box 31 through the hook 33 that is installed on main counterweight box 31 both sides, main counterweight box 31 and auxiliary counterweight box 31 The inside of the counterweight 32 is filled with cement, sand and iron. The staff c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com