Technique and process for renovating life-terminating carbon / carbon aviation brake disc

A brake disc, aviation technology, applied in the direction of friction linings, mechanical equipment, etc., can solve problems such as damage and environmental pollution, and achieve the effects of simple process, reduced equipment, and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention provides a kind of refurbishment of a carbon / carbon aviation brake disc and its technology after the end of life, and the specific implementation steps are as follows:

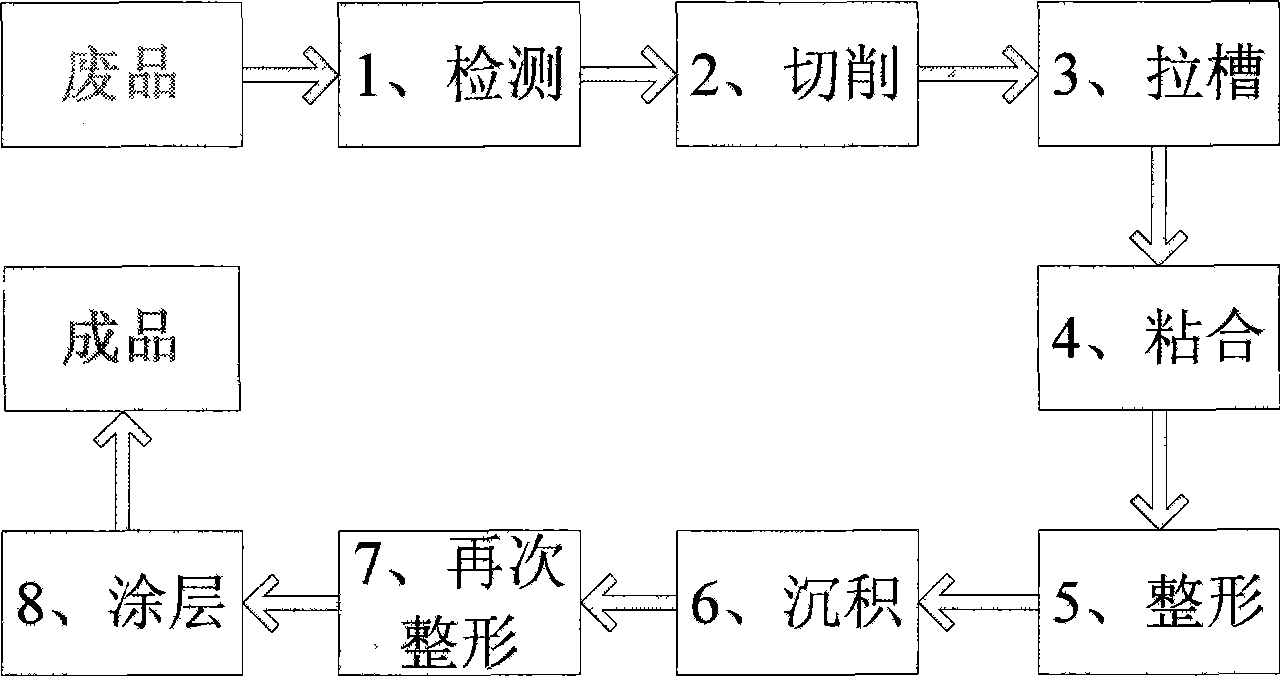

[0023] Such as figure 1 As shown, the technical process of the present invention includes 8 processes, including: 1. Detection process, 2. Cutting process, 3. Grooving process, 4. Bonding process, 5. Shaping process, 6. Deposition process, 7. Again Shaping process, 8, coating process and other components.

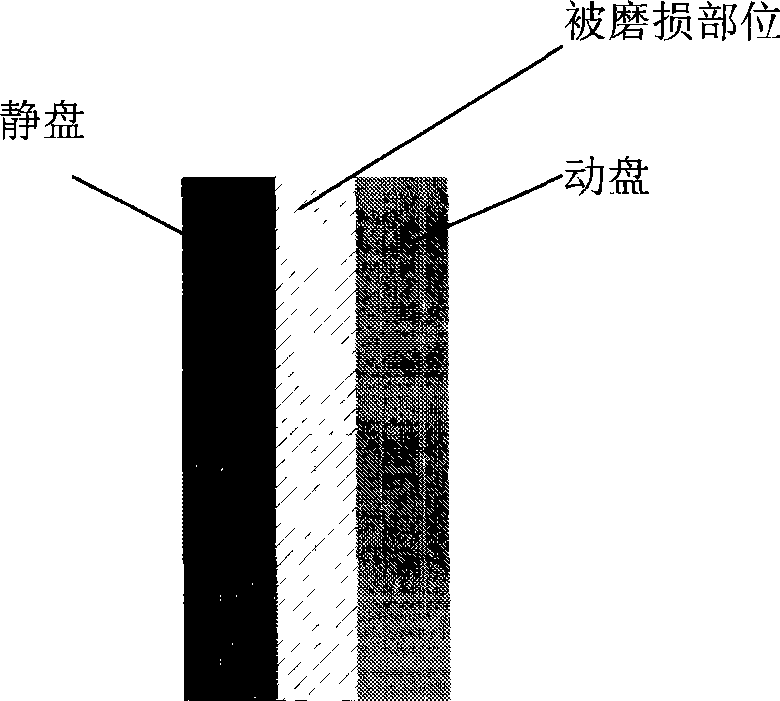

[0024] 1. Inspection process. First of all, check the appearance of the brake disc after the end of life, observe the degree of wear on the surface of the brake disc, and whether there are other damages, such as cracks, etc.; Density, strength and other indicators determine whether the repair is possible or not, and the correction index is set, that is, the cutting thickness.

[0025] 2. Cutting process. According to the correction index set in the inspection process, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com