Radiation solidified rubberized adhesive/sealant

A technology of radiation curing and adhesives, which is applied in the direction of adhesives, non-polymer organic compound adhesives, sealing devices, etc., and can solve problems such as hindering light emission and high melting temperature of temperature-sensitive devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

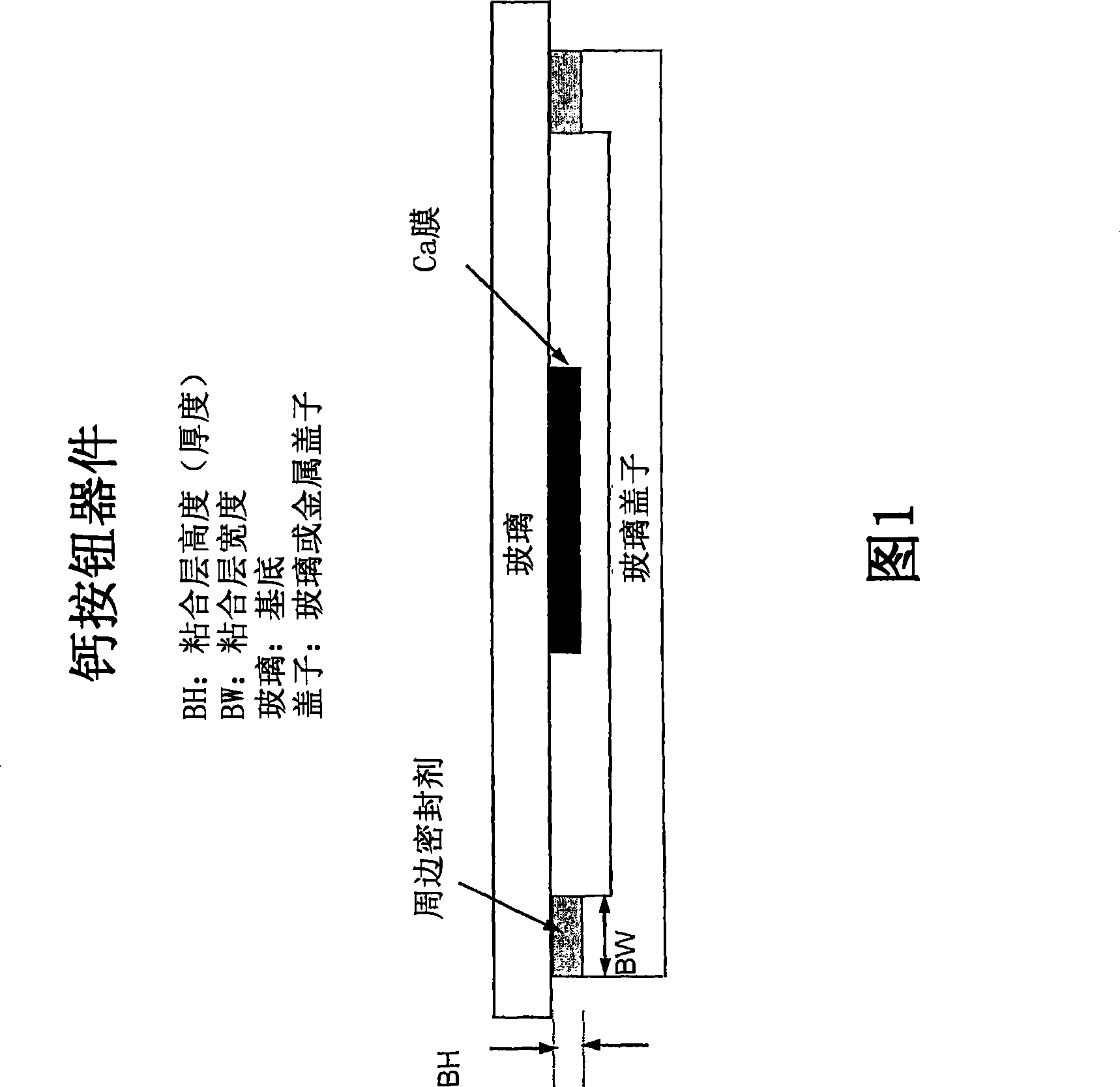

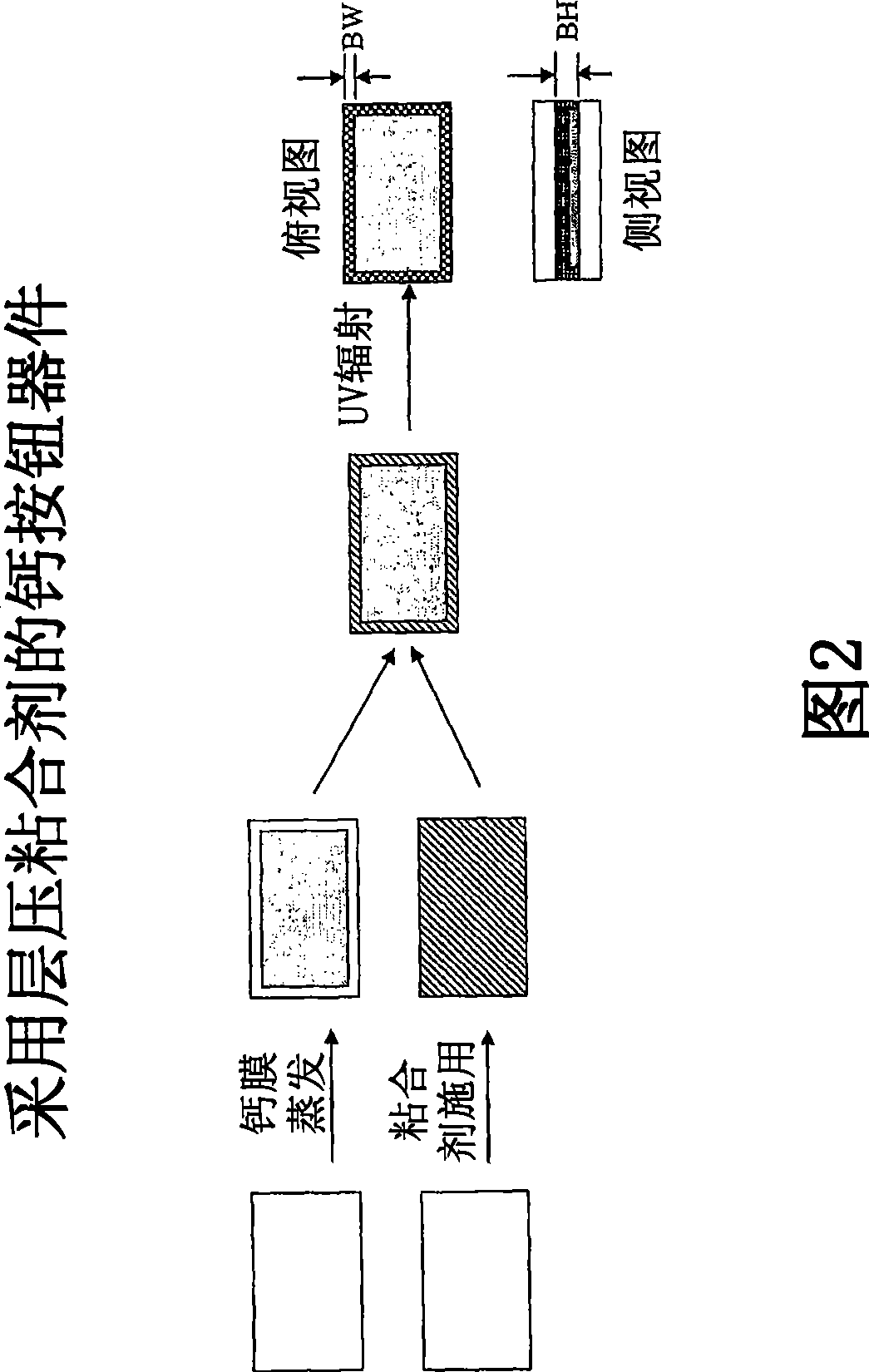

[0027] The moisture barrier performance of an encapsulant can be evaluated by a test known as the Ca-button test, in which the time required for a thin film of calcium metal sealed into a device to decay into a calcium salt by reacting with water is measured. The longer the lifetime of the calcium metal film before decay, the lower the penetration of moisture into the device and the better the sealant / adhesive protects the device.

[0028] The calcium-button device used in these examples is shown in Figure 1, where BH is the bondline height (thickness) of the perimeter sealant / adhesive; BW is the bondline width of the perimeter sealant / adhesive; The glass is the substrate on which the calcium metal film is placed; and the lid is the glass or metal lid used to seal the resulting device.

[0029] The device is filled with N 2 assembled in the glove box. Ca thin films were first evaporated by vapor deposition on glass substrates (26 mm x 15.5 mm x 1.1 mm) (L x W x H) with a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com