Quick energy-saving automatic aligning cutting-off device

A cutting machine and automatic technology, which is applied in the field of automatic straightening and cutting machines, can solve the problems of production cost and electric energy waste, user troubles, oil pump start-up in advance, etc., to reduce processing and production costs, low manufacturing and production costs, and reduce multi-section variable speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

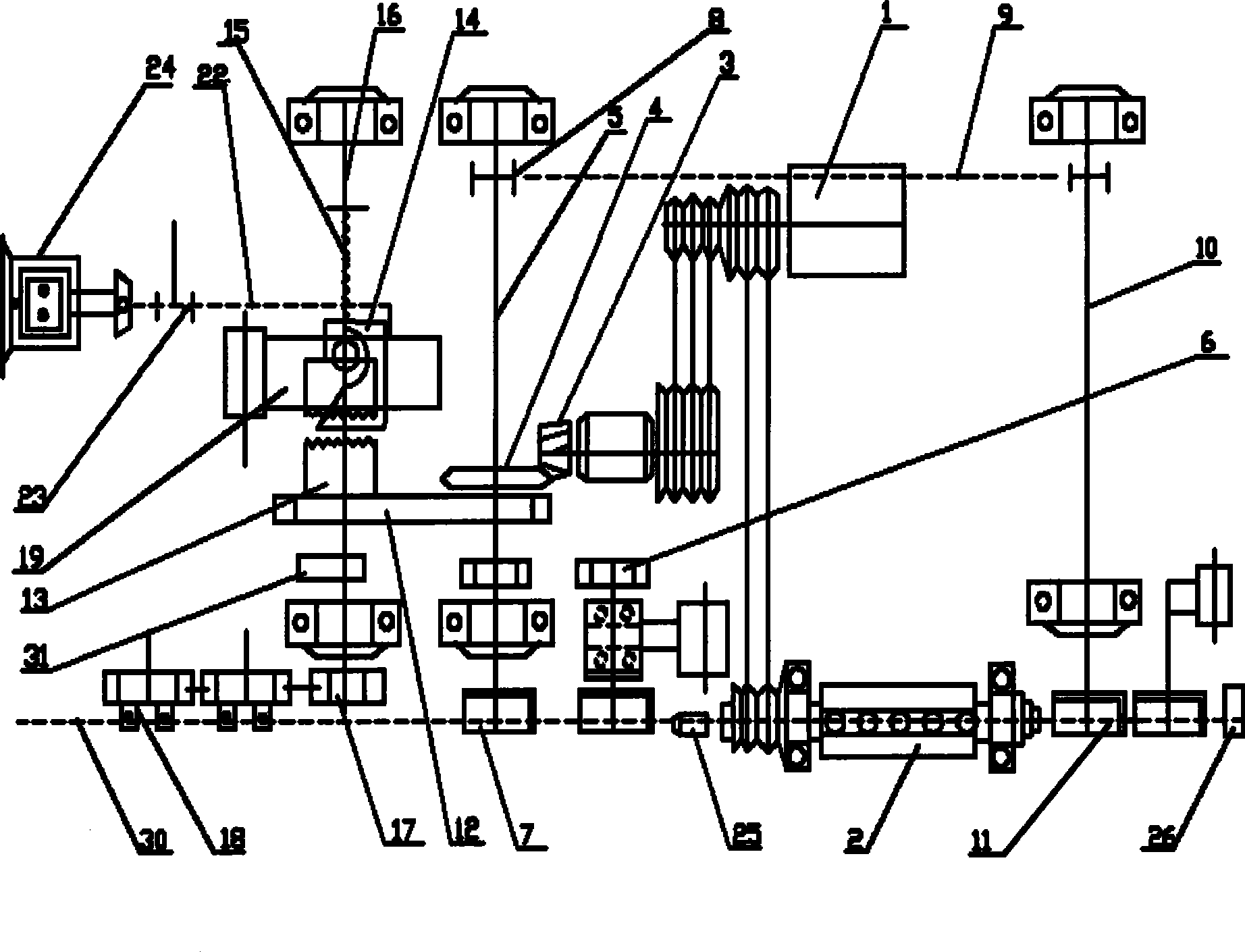

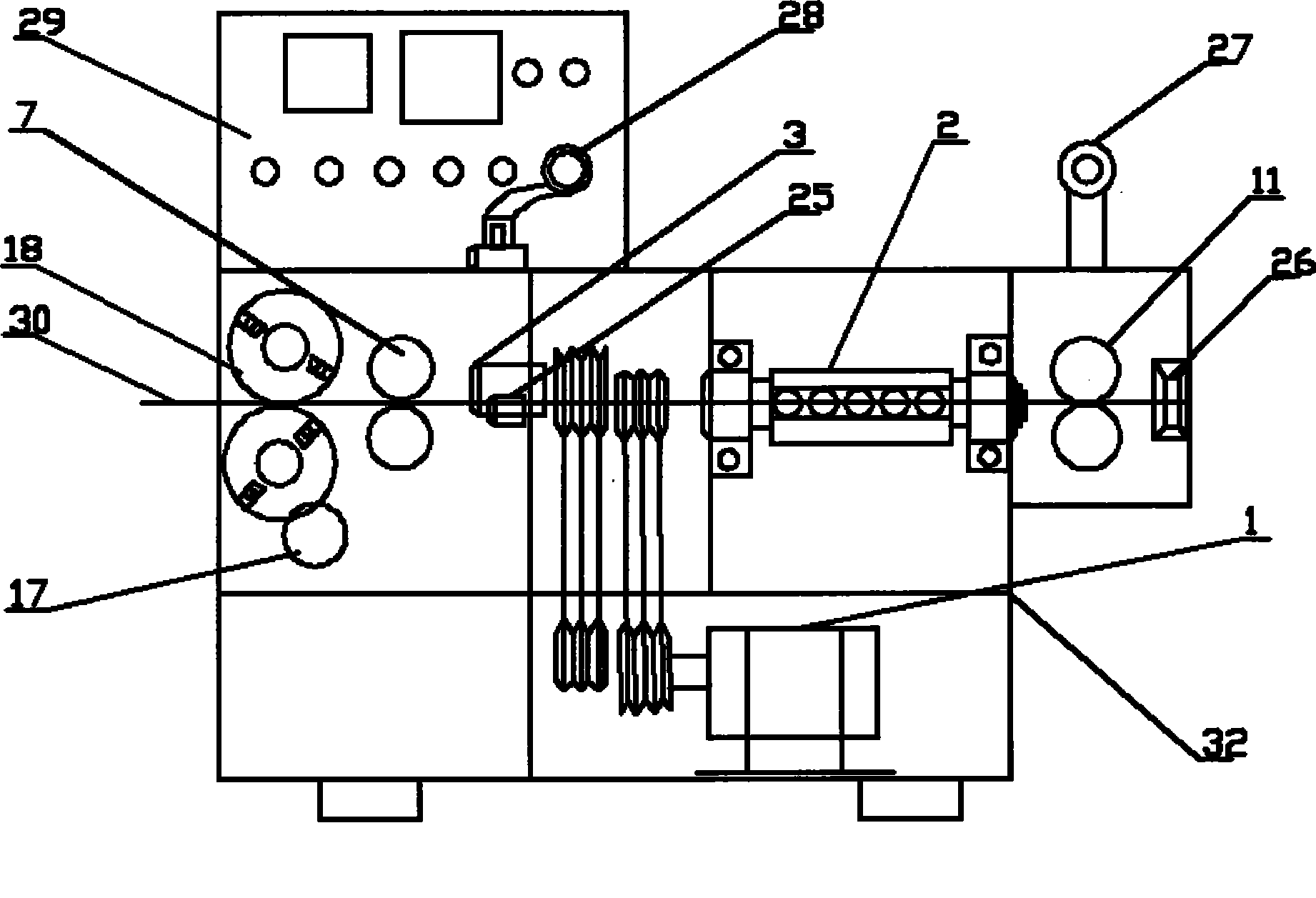

[0033] Embodiment 1, fast and energy-saving automatic straightening and cutting machine, wherein: the motor 1 drives the straightening cylinder 2 through one belt; the motor 1 drives the angled pulley, the rear axle angle gear 3, and the disc gear 4 in sequence through another belt at the same time , Front feeding main shaft 5; Front feeding main shaft 5 drives feeding assembly and traction assembly; Disk gear 4 drives shearing assembly.

Embodiment 2

[0034] Embodiment 2, fast and energy-saving automatic straightening and cutting machine, wherein: the feeding assembly includes front sprocket 8, front chain 9, rear feeding main shaft 10 to drive feeding roller 11; traction assembly includes front material shaft gear 6, driving traction Roller 7; front feed main shaft 5 one ends drive traction roller 7 through front material shaft gear 6; All the other are with embodiment 1.

Embodiment 3

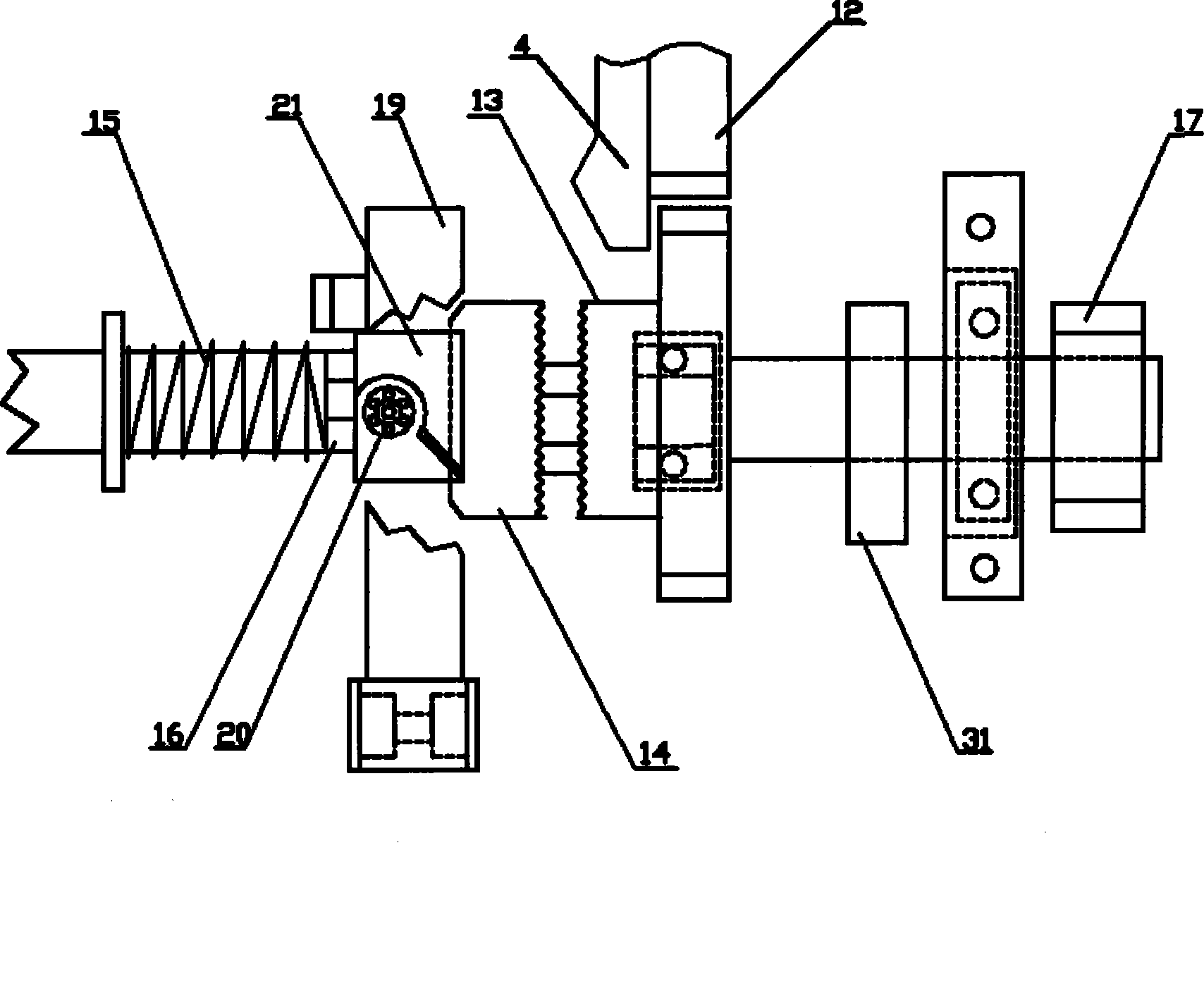

[0035] Embodiment 3, a fast and energy-saving automatic straightening and cutting machine, wherein: the shearing assembly includes a spur gear 12, a clutch assembly, a pinion 17, and a shearing gear 18; the disc gear 4 passes through the spur gear 12 and the clutch assembly in sequence 1. The pinion gear 17 drives the shearing gear 18; the shearing gear 18 drives the shearing knife that can cut off the wire. All the other are with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com