Spiral squeezing type sludge dewatering equipment

A technology of sludge dewatering machine and screw extrusion, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of easily clogging the gap between the static filter and the dynamic filter, reducing the service life of the device, and reducing the overall dehydration effect. , to achieve the effect of convenient mud discharge, less cleaning water and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

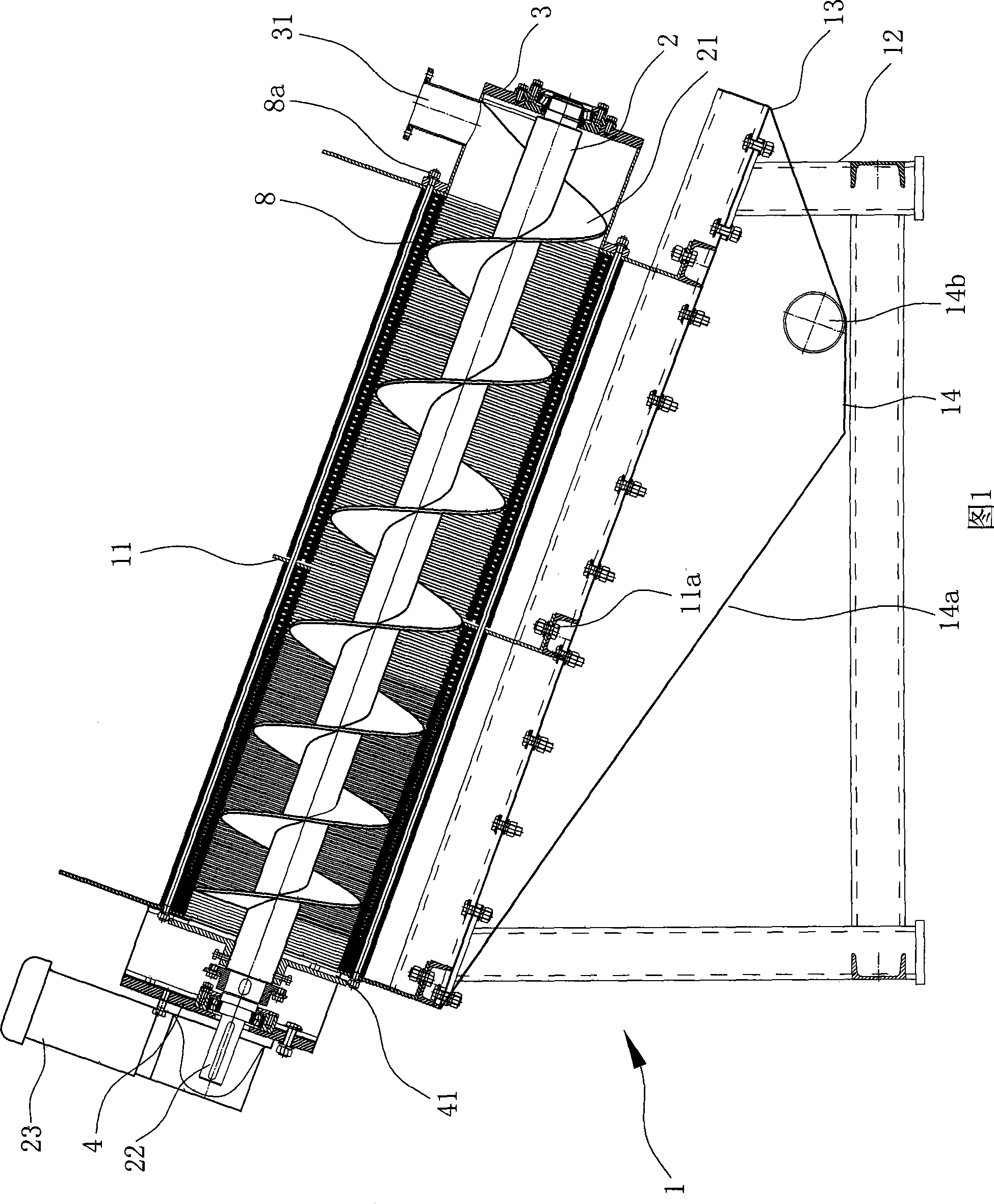

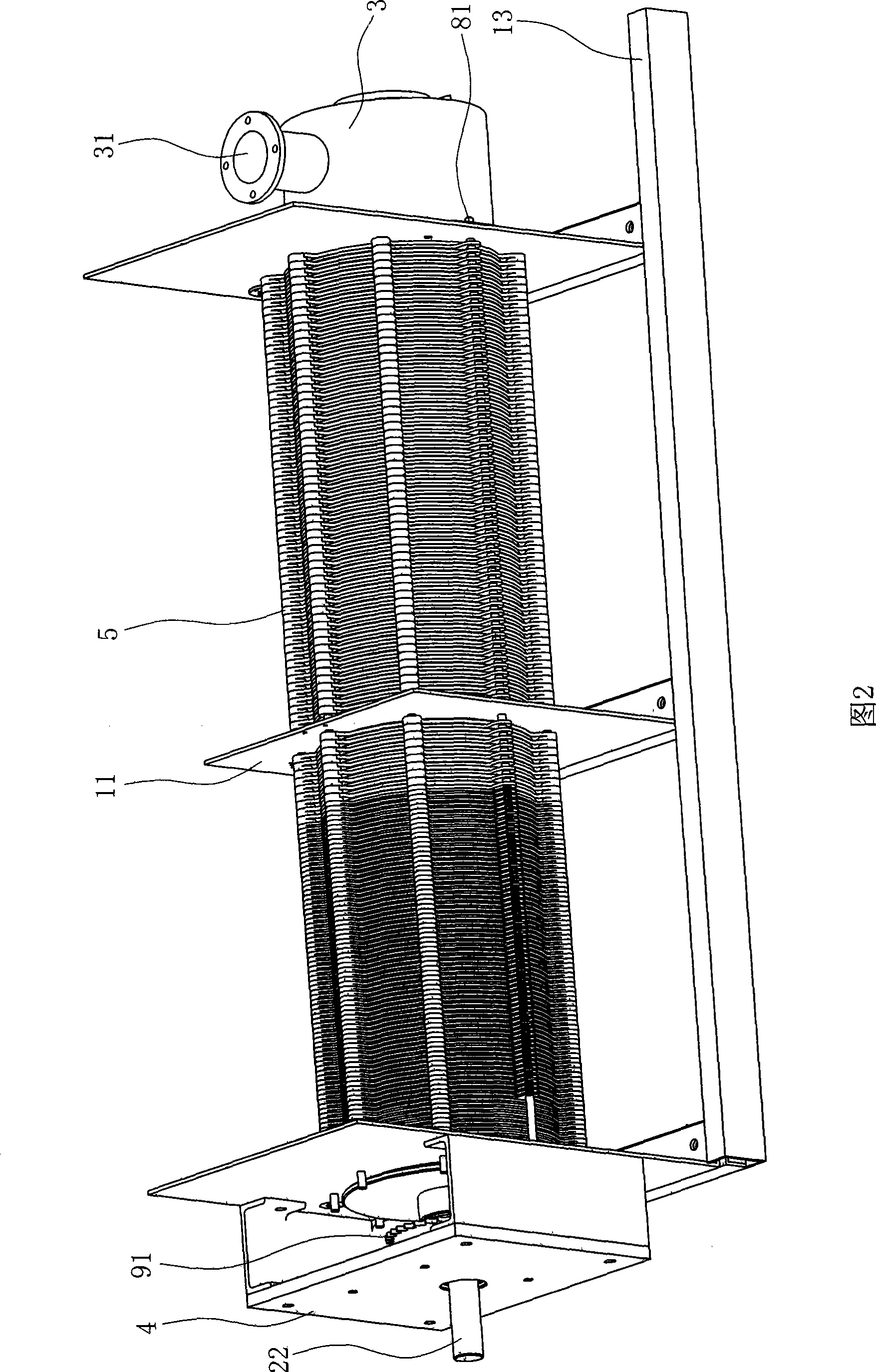

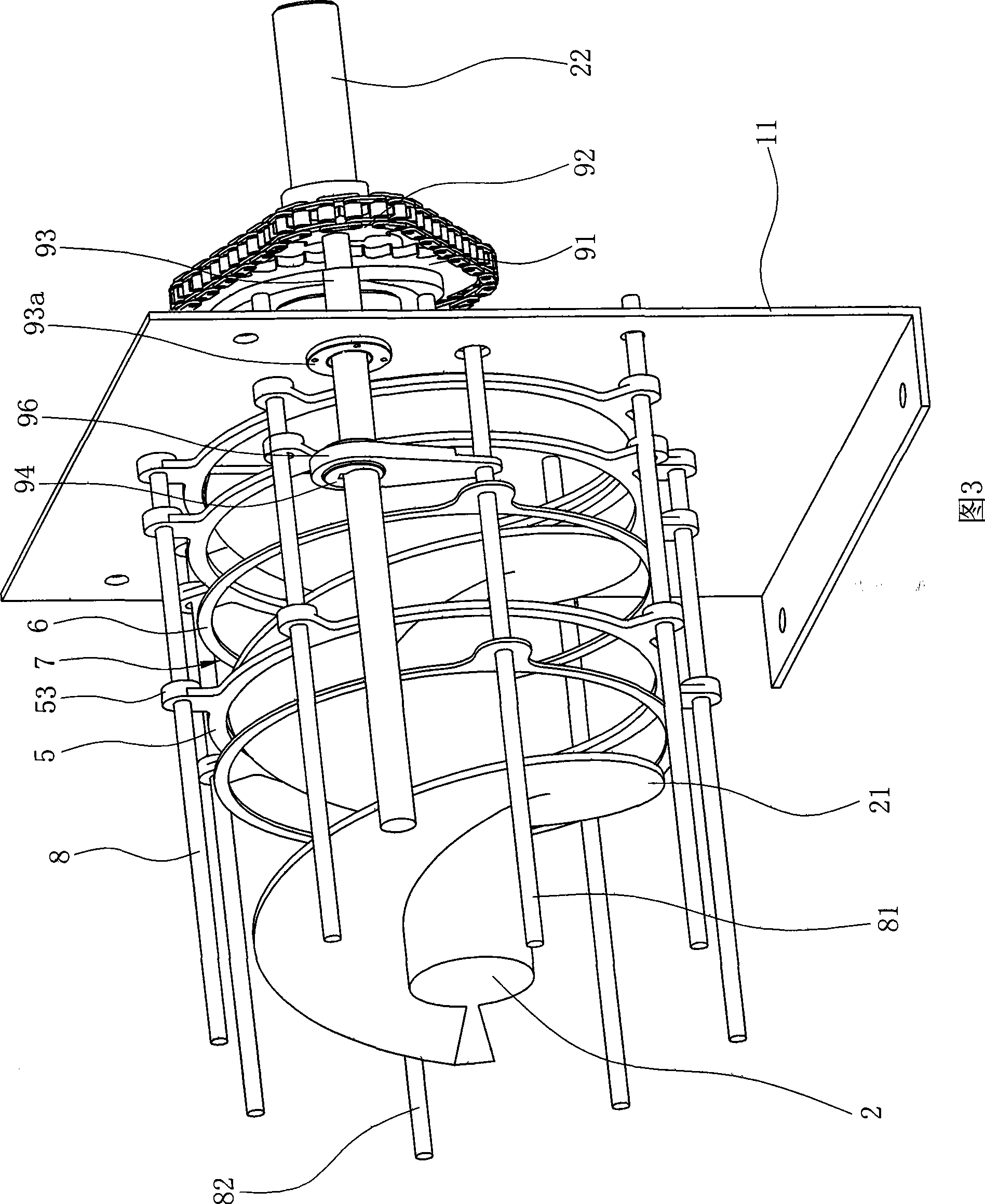

[0032] As shown in Figures 1 to 7, the screw extrusion sludge dewatering machine includes an organic base 1, a water inlet part, a mud outlet part 41, a water outlet part, and is installed inside the machine base 1 and has a helical blade 21 on the periphery. The screw shaft 2, the motor 23 that drives the screw shaft 2 to rotate, and the filter group formed by a plurality of annular static filter discs 5 and annular dynamic filter discs 6 that are set at the periphery of the screw shaft 2 at intervals;

[0033] Wherein, the base 1 includes a bracket and a plurality of parallel supporting plates 11 fixed on the bracket. In this embodiment, three supporting plates 11 are provided, and the bracket includes legs 12 and a 12 The fixed frame 13 whose top and rear ends are inclined downwards, and each support plate 11 is fixedly connected with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com