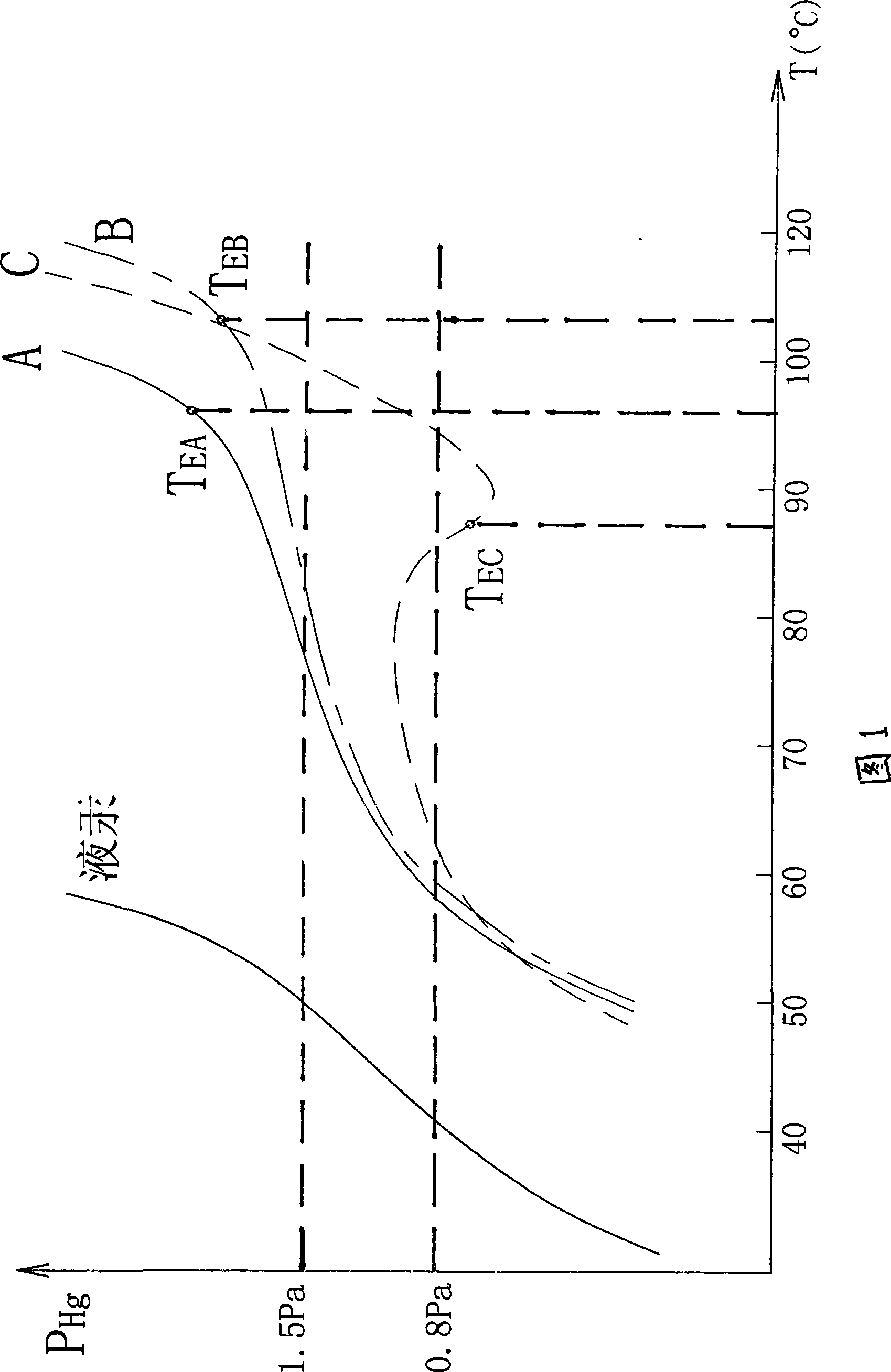

Bi-Pb-Ti-Hg alloy for low pressure Hg discharge lamp

A discharge lamp and low-pressure technology, applied in the field of bismuth-lead-tin amalgam, can solve the problems of reduced radiation efficiency, low luminous efficiency, large dispersion of optoelectronic parameters, etc., and achieve the effects of improving stability and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

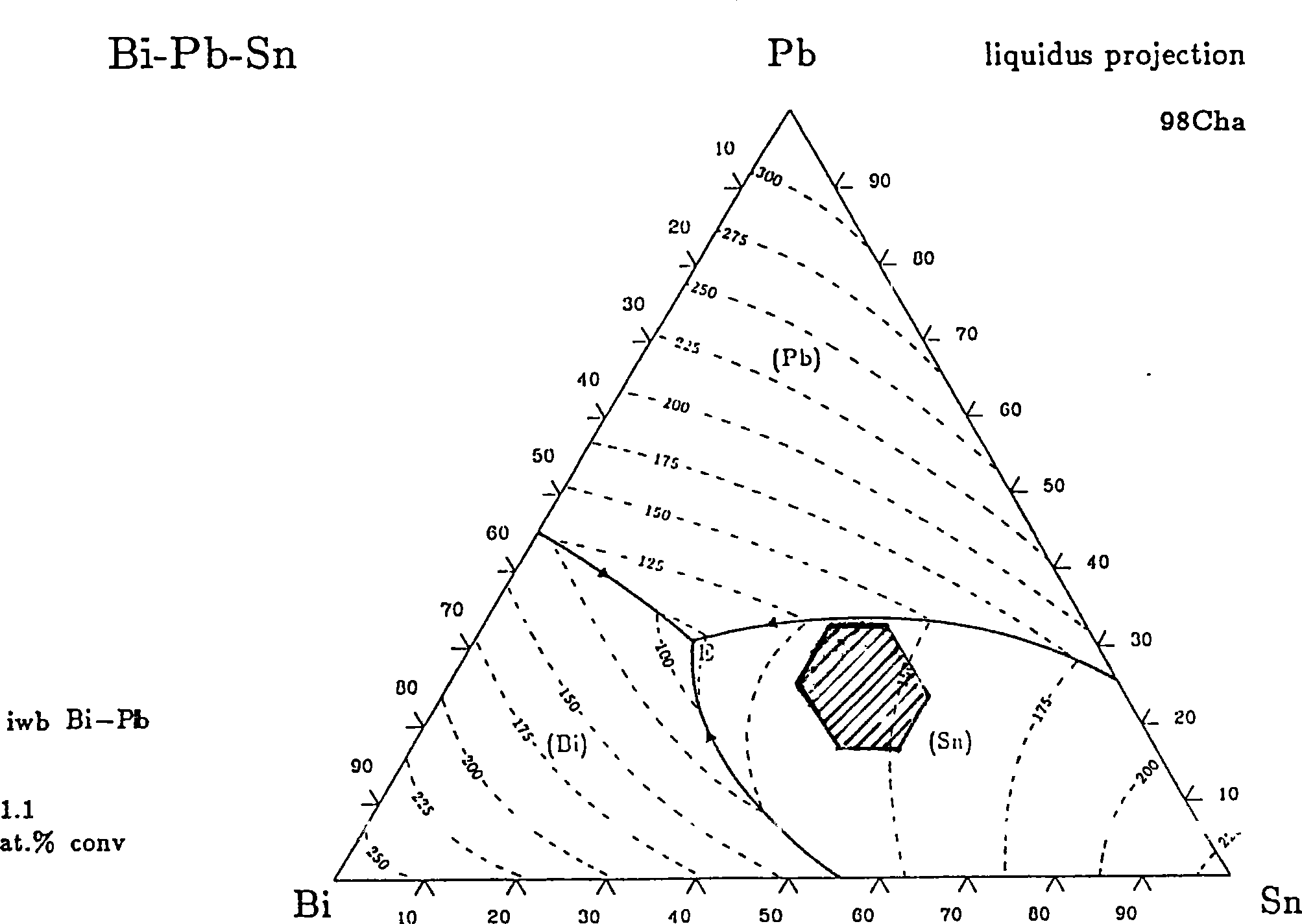

[0015] Example 1: The bismuth lead tin amalgam was melted and dropped into pellets by mass ratio (m / m): Bi:Pb:Sn:Hg=30:40:25:5. Among the 11w compact fluorescent lamps with outer bulb, the average luminous efficiency is high, and the light output of the lamp is stable and consistent.

Embodiment 2

[0016] Example 2: The bismuth lead tin amalgam was melted and dropped into pellets according to the mass ratio (m / m): Bi:Pb:Sn:Hg=45:22:30:3. Among the 13w compact fluorescent lamps with outer bulb, the average luminous efficiency is high, and the light output of the lamp is stable and consistent.

Embodiment 3

[0017] Example 3: Bismuth lead tin amalgam is made into pellets by mass ratio (m / m): Bi:Pb:Sn:Hg=32:27:40:1, which can be applied to pipe diameter φ10mm and power 9 -15w in compact fluorescent lamp with outer bulb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com