Cotton feeding roller component for rotor spinning machine

A technology of rotor spinning machine and components, applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problem of deterioration of yarn evenness, uneven transfer amount, and wear of cotton feeding board. and other problems, to achieve the effect of sufficient carding, improving the efficiency of impurity removal, and uniform transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

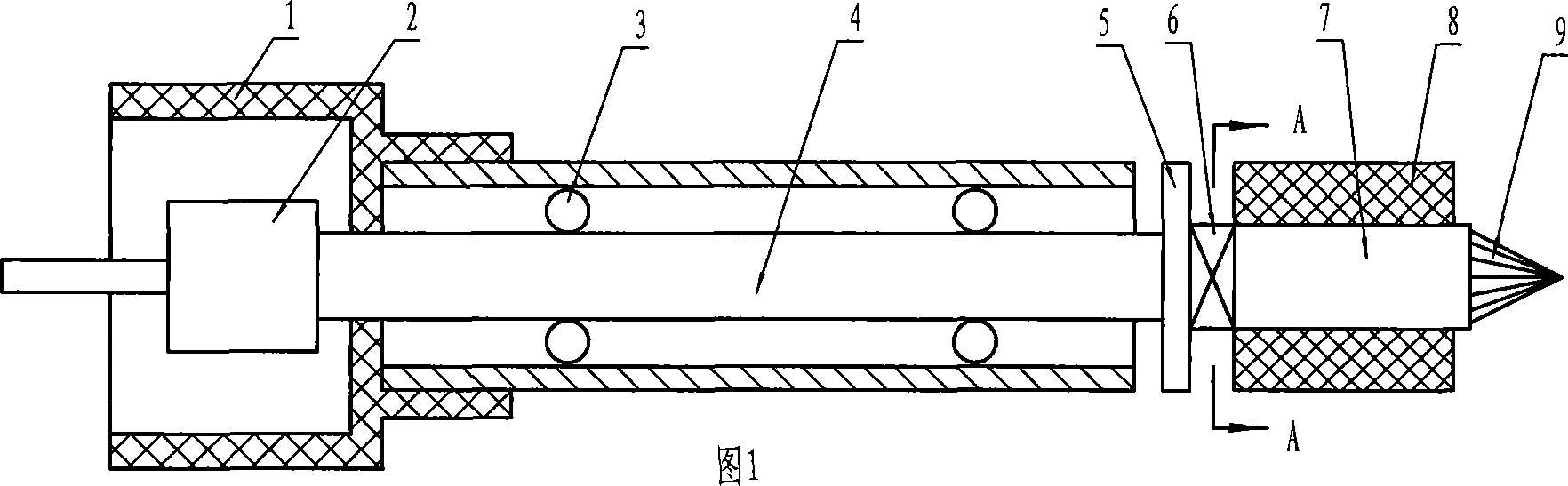

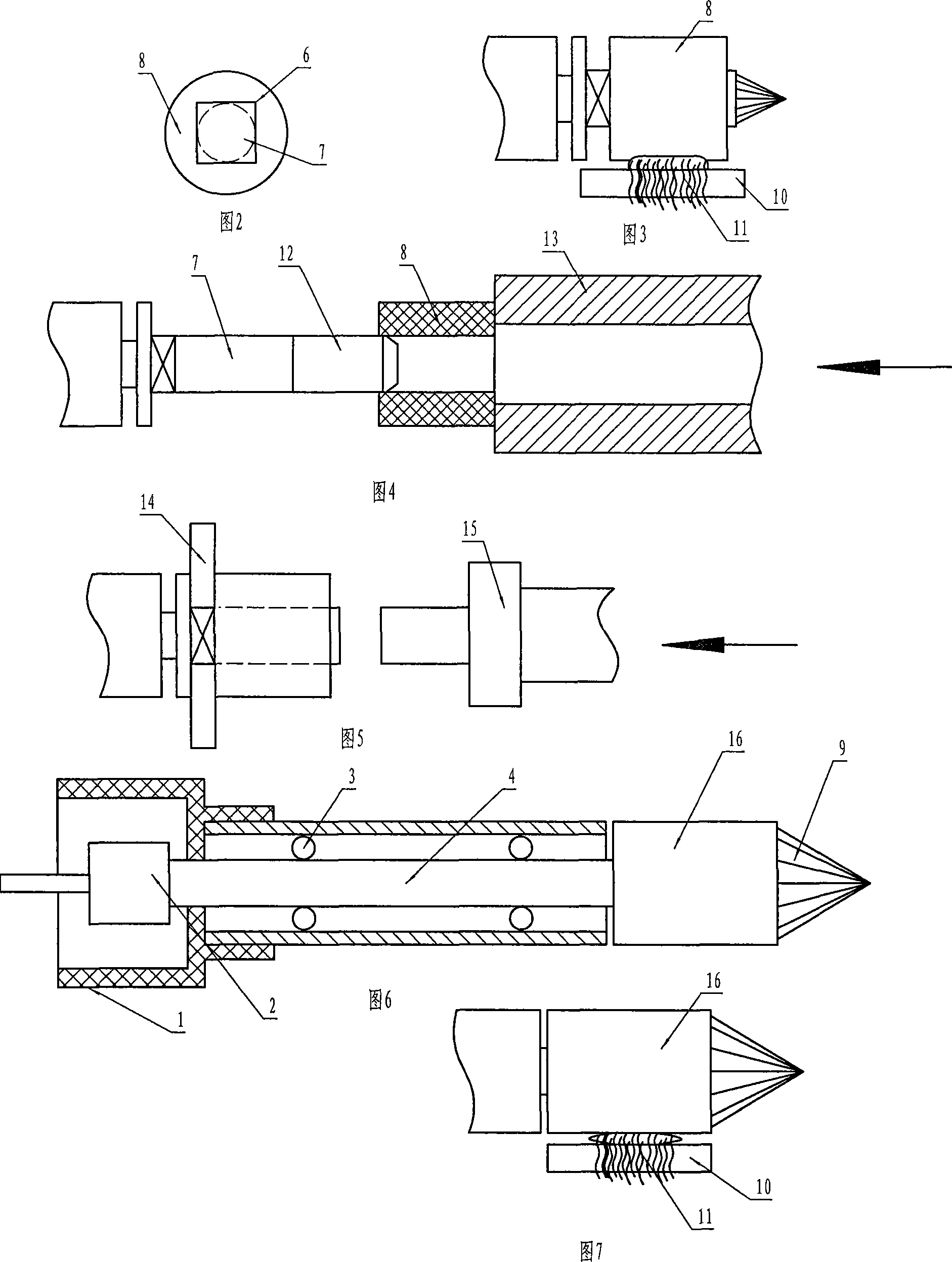

[0018] Referring to Fig. 1, the present invention comprises an electromagnetic clutch 2, a dust cover 1, a cotton feeding roller bearing 3, a manual button 9 and a cotton feeding roller, the cotton feeding roller is composed of a roller shaft 4 and a cotton feeding position, and the roller shaft is supported by a roller bearing , the manual button is located at one end of the roller shaft. The main improvement of the present invention is that the roller shaft 4 and the cotton feeding part are designed as separate assembly structures, and the cotton feeding part adopts an elastic rubber roller 8 made of polyurethane material, and a rubber roller is installed beside the manual button of the roller shaft. Section 7, the rubber roller is set in the rubber roller installation section and closely cooperates with it. As shown in Figure 3, after the cotton feeding part of the present invention adopts rubber rollers, elastic jaws are formed between it and the cotton feeding plate 10, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com