Intelligent duplicate power supply conversion switch

A dual-power conversion and dual-power switching technology is applied to electric switches, high-voltage/high-current switches, and power devices inside switches. Effects of cost reduction and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

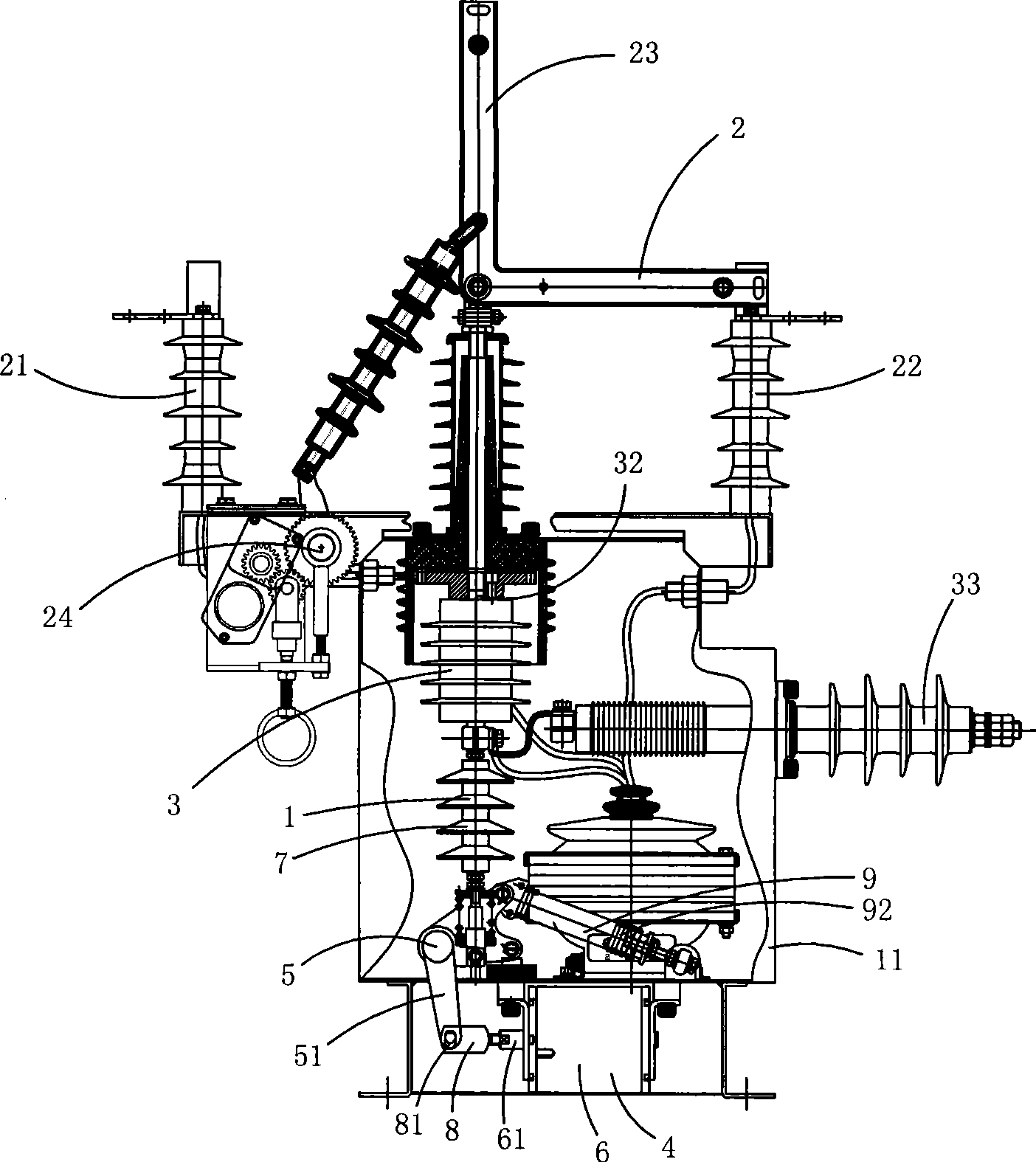

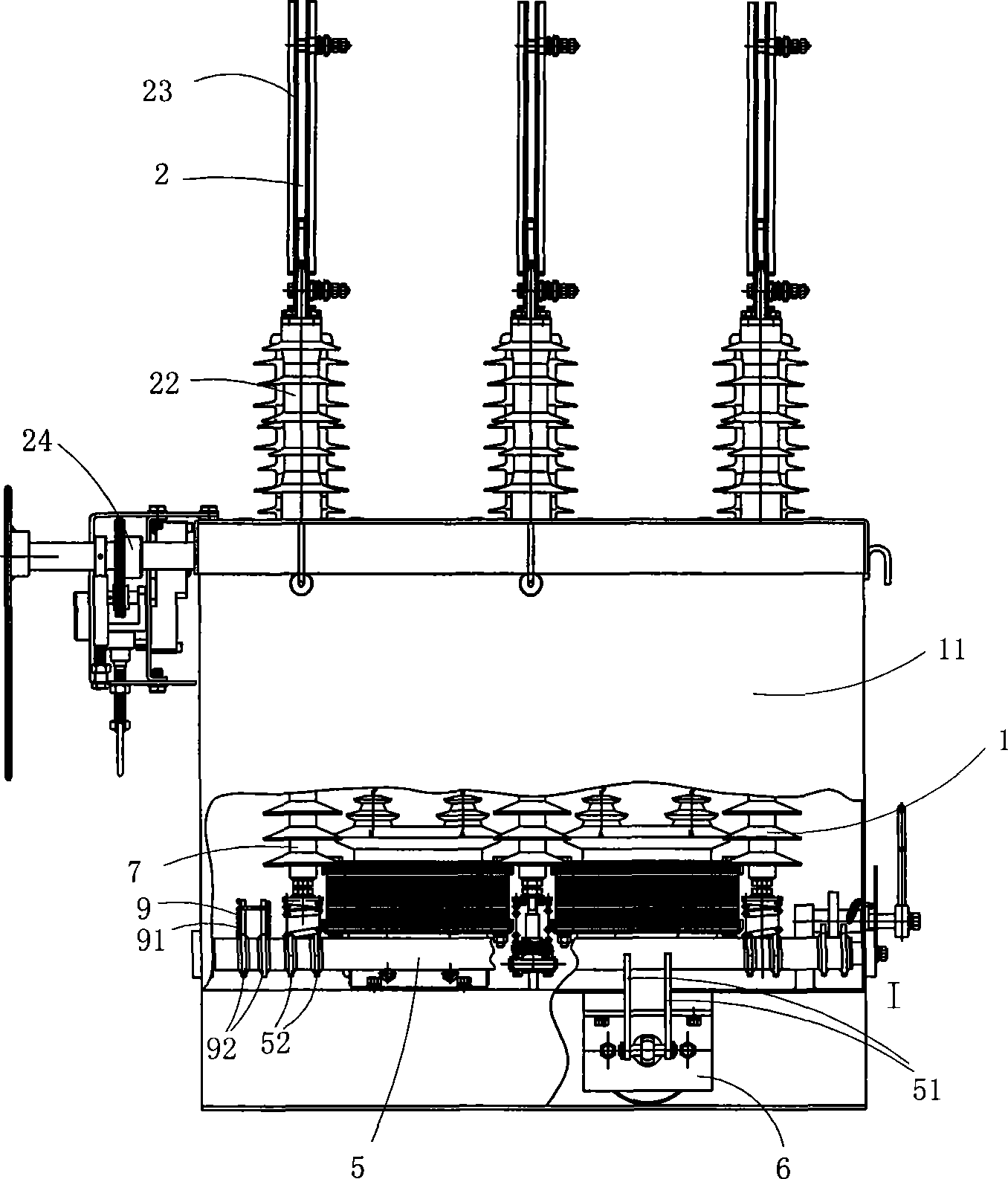

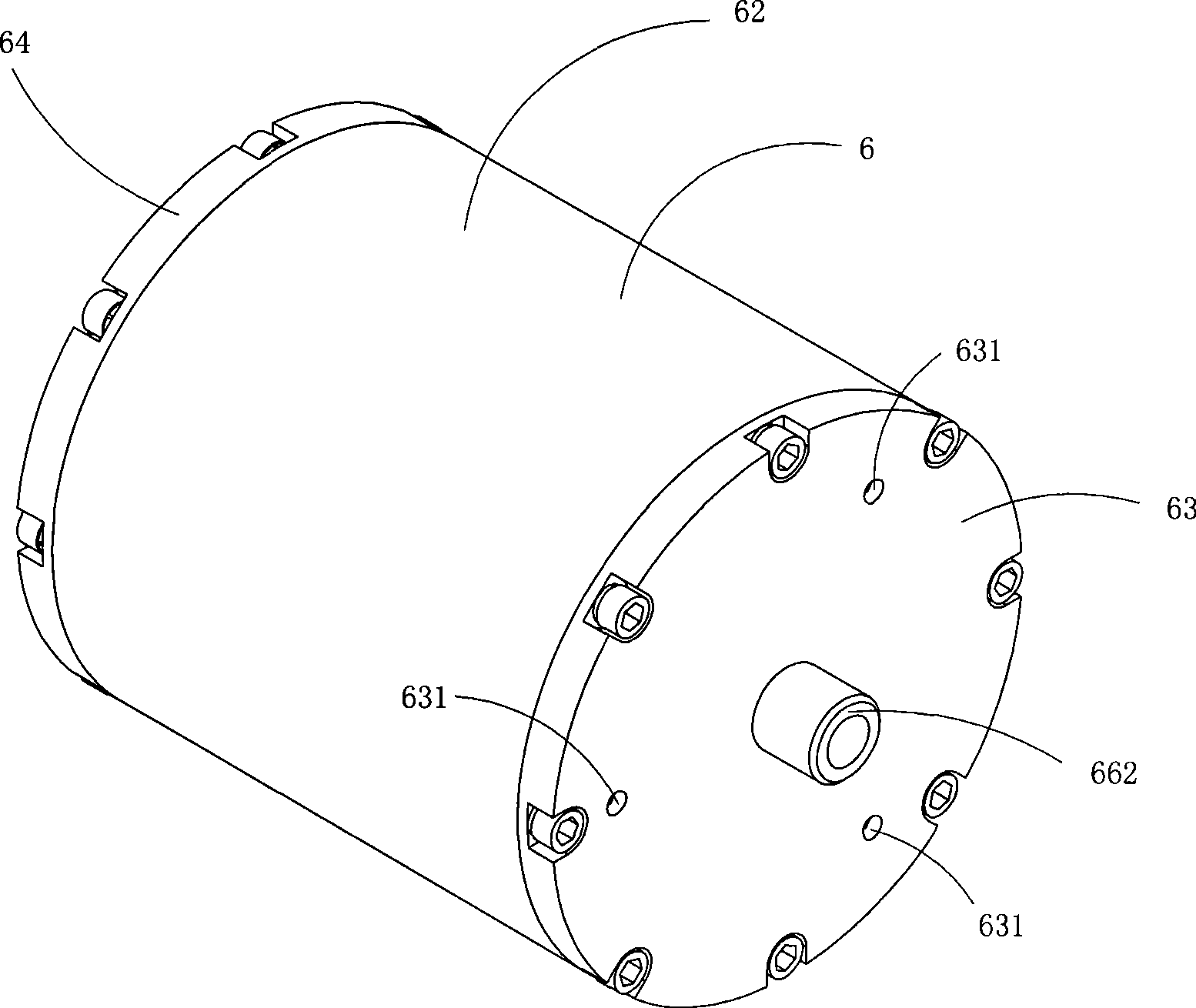

[0035] Figure 1 to Figure 7 A first embodiment of the invention is shown in which, figure 1 is a structural schematic diagram of the first structure of the present invention; figure 2 Yes figure 1 The structural diagram of the intelligent dual power transfer switch shown when viewed from another angle; image 3 Yes figure 1 A schematic diagram of a three-dimensional structure of the permanent magnet drive mechanism in the intelligent dual power transfer switch shown; Figure 4 Yes image 3 The schematic diagram of the structure of the permanent magnet drive mechanism when viewed from the direction of the front cover; Figure 5 Yes Figure 4 Sectional view along line A-A; Image 6 Yes image 3 A schematic diagram of a three-dimensional structure of the permanent magnet drive mechanism shown after removing the front cover; Figure 7 Yes image 3 A schematic diagram of a half-section structure of the permanent magnet drive mechanism shown after removing the permanent ...

Embodiment 2

[0047] Figure 8 It is a half-sectional structural schematic diagram of the permanent magnet drive mechanism used in the second structure of the present invention after the permanent magnet is removed, showing the second embodiment of the present invention.

[0048] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 8 , the arrangement of the permanent magnets is different. In this embodiment, the inner wall of the housing 62 is provided with an annular groove 100 for limiting the permanent magnet 67 , and the permanent magnet 67 is disposed in the groove 100 . This structure enables the adjusting bolt to limit the yoke ring and at the same time limit the permanent magnet to avoid loosening and displacement due to vibration.

Embodiment 3

[0050] Figure 9 It is a schematic diagram of the half-section structure of the permanent magnet drive mechanism used in the third structure of the present invention after removing the permanent magnet, showing the third embodiment of the present invention.

[0051] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 9 , the arrangement of the permanent magnets is different. In this embodiment, the outer wall of the yoke ring 68 is provided with an annular groove 100 for limiting the permanent magnet 67 , and the permanent magnet 67 is disposed in the groove 100 . This structure enables the adjusting bolt to limit the yoke ring and at the same time limit the permanent magnet to avoid loosening and displacement due to vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com