Single transplanted magnet steel permanent magnet synchronous motor

A permanent magnet synchronous, single-planted magnetic steel technology, applied in the field of electric motors, can solve the problems of poor demagnetization resistance, increased cost, increased amount of magnetic steel, etc., and achieves obvious advantages in energy saving, self-starting, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

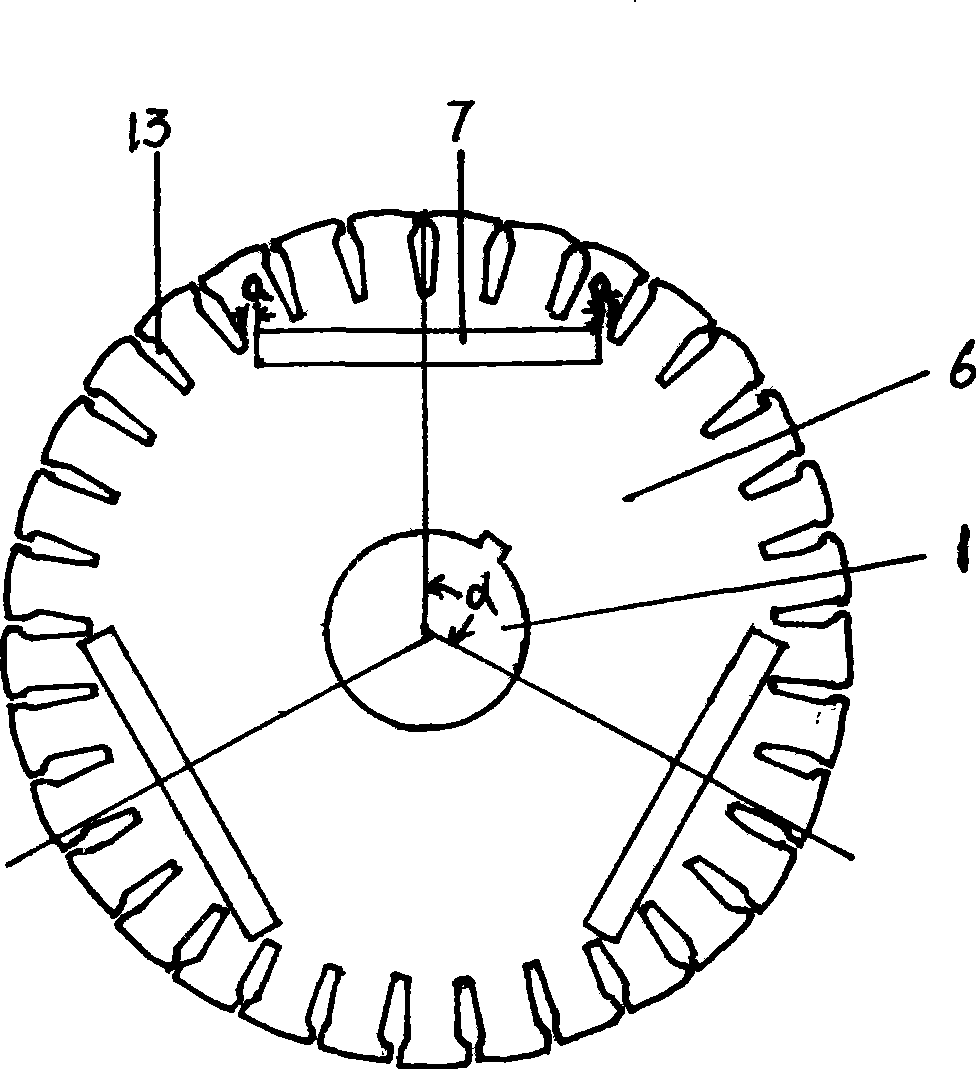

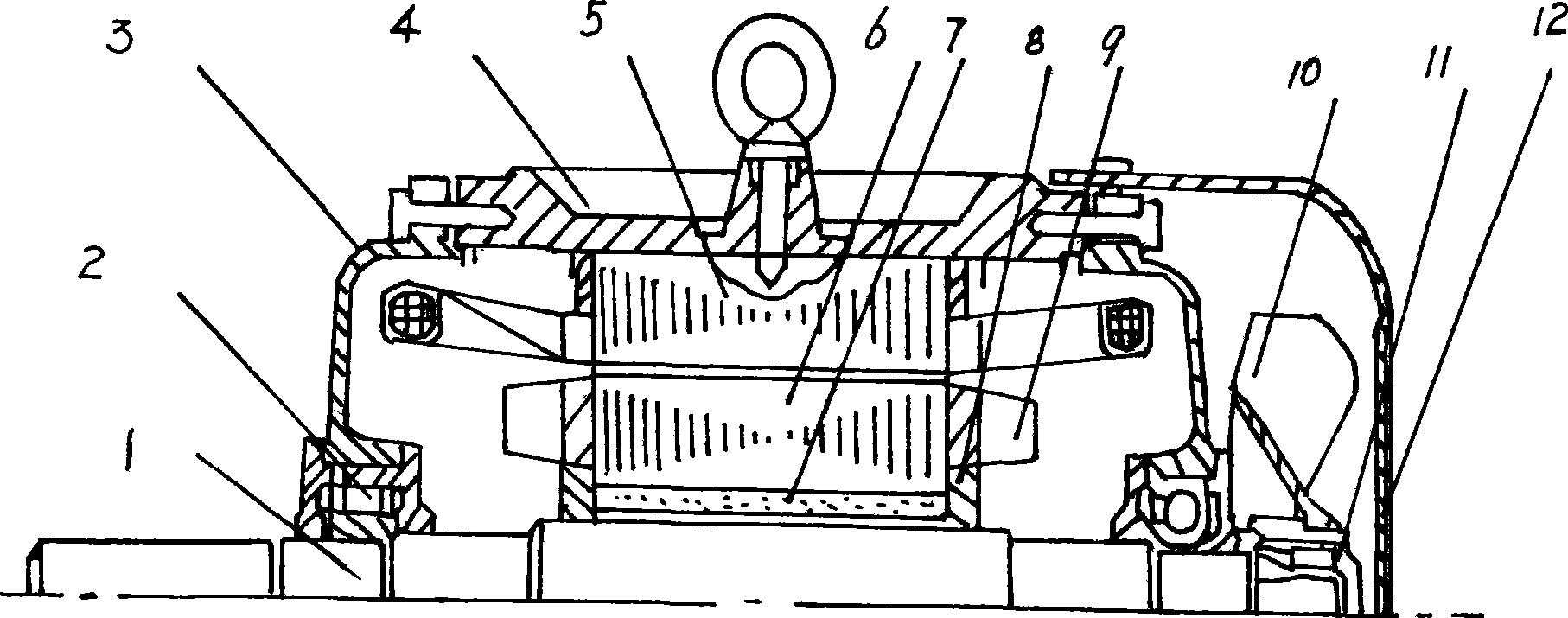

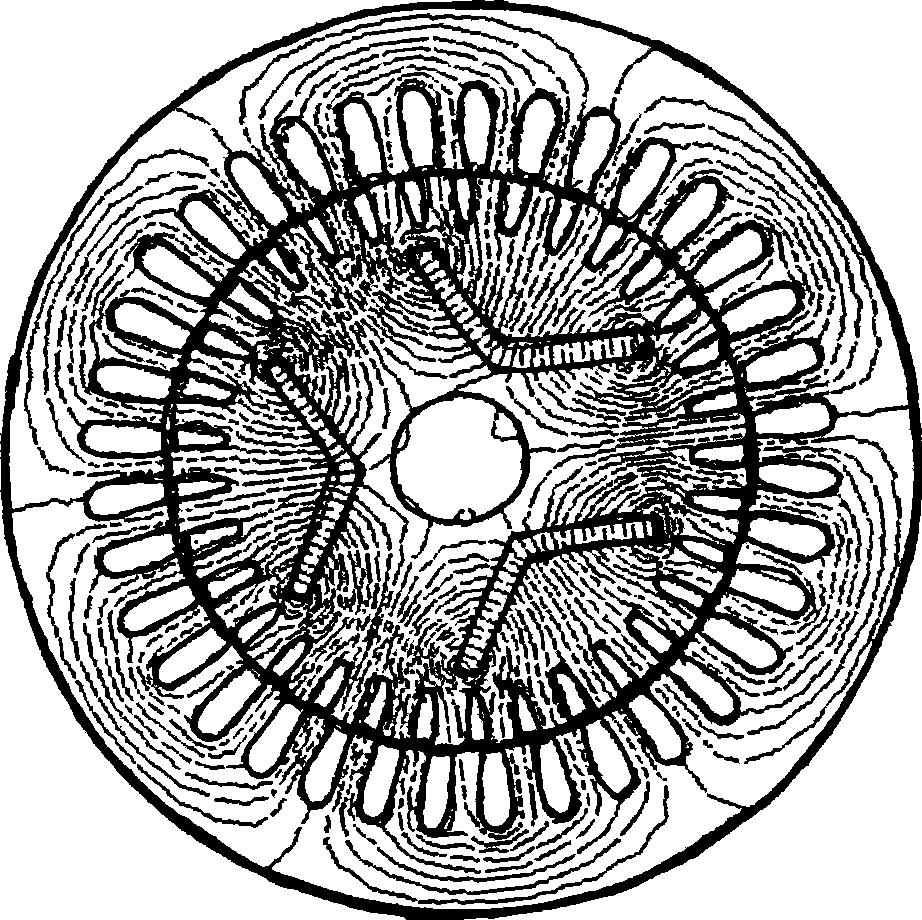

[0017] A permanent magnet synchronous motor with a single-planted magnet includes a rotating shaft 1, a bearing 2, an end cover 3, a stator core 5, and a rotor core 6 coupled with the rotating shaft 1; : A slot space 7 is opened on the rotor core 6; permanent magnets of the same polarity are placed in the slot space 7; the number of the permanent magnets is equal to the number of pole pairs of the motor. The space included angle between the slot spaces 7 is α=360 / p degrees, and p is the number of pole pairs of the motor. A rotor slot 13 is provided on the rotor core 6; aluminum and / or copper connected to the end ring 9 are cast into the rotor slot 13. There is a magnetic bridge a between the slot space 7 and the rotor slot 13; the magnetic bridge a is between 1.5 and 2.0 mm; the slot space 7 is a straight slot, an arc slot, a V-shaped slot, a U-shaped slot or a W -Shaped slot; the pole arc coefficient of the permanent magnet steel is between 0.95 and 1.0. A cooling fan 10 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com