Inlet distortion and recovery control system

A control system, air entry technology, applied in the direction of charging system, aircraft control, engine control, etc., can solve the problems of inefficiency, complex aircraft weight and/or volume, unadjustable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

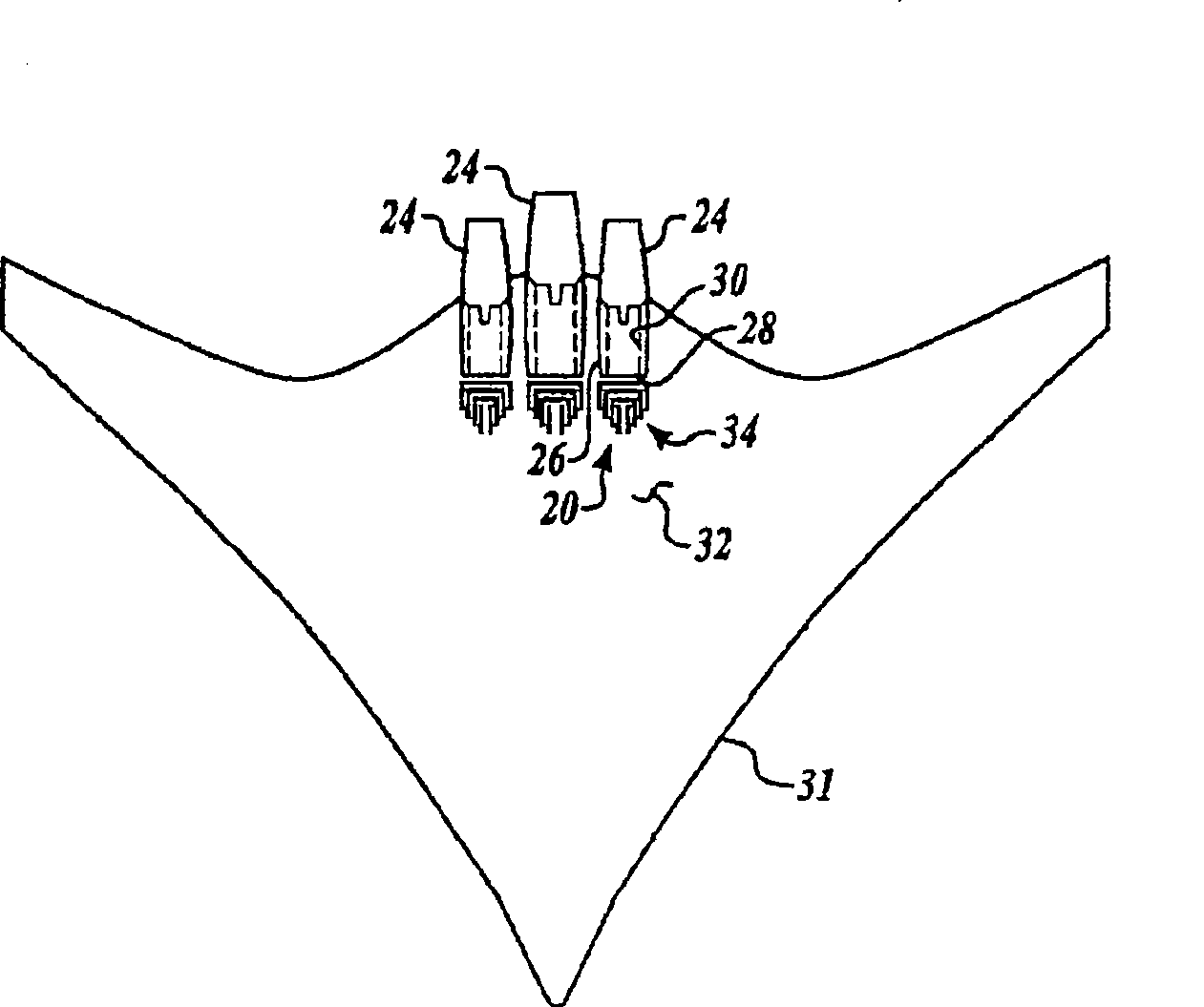

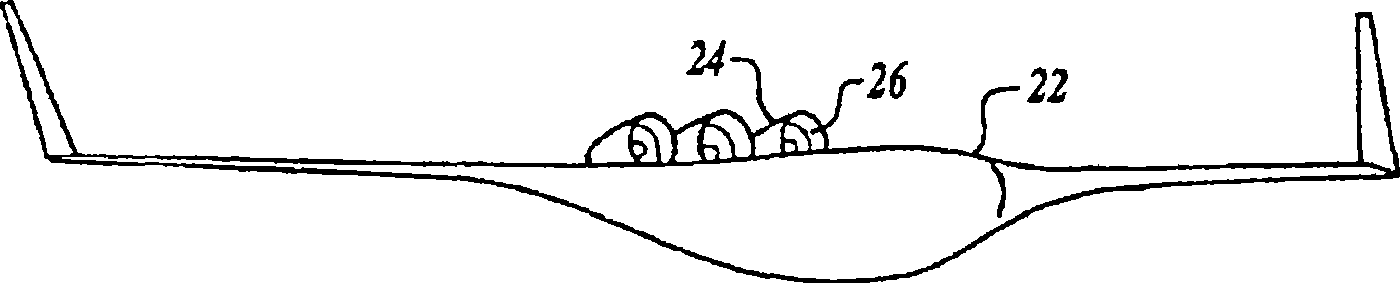

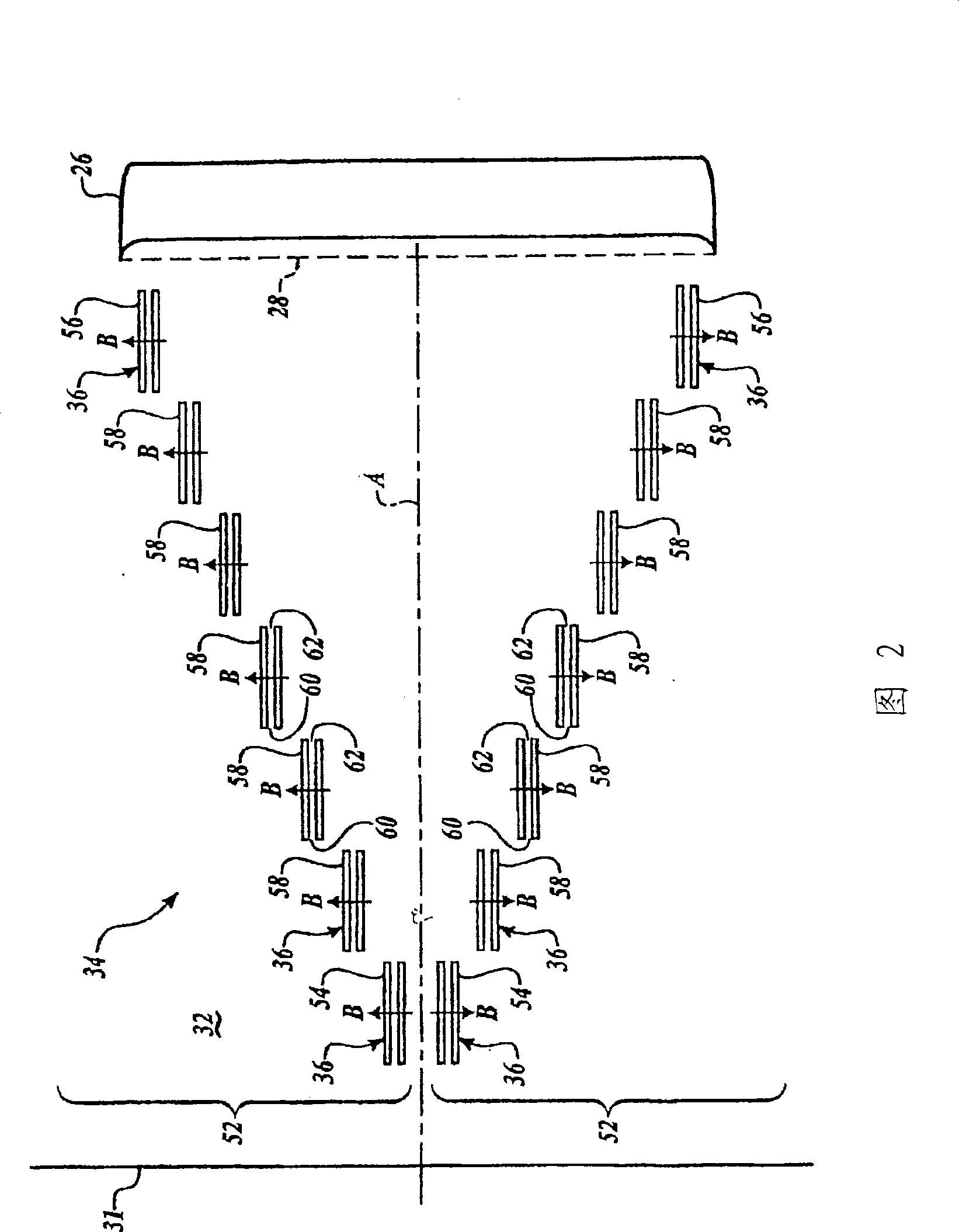

[0025] by reference Figure 1A and 1B And to describe generally, the exemplary air intake system 20 is installed on an aircraft 22 to minimize or, in some cases, eliminate boundary layers and thereby provide improved quality intake air to corresponding engines 24 . The system 20 can be tuned to meet propulsion and power demands across the entire aircraft hull more efficiently than prior art techniques at various speeds, altitudes, and angles of attack or sideslips. although Figure 1A and 1B While the aircraft 22 is shown as a hybrid wing-like body with the engine at the rear, it is understood that the system 20 may take the form of any machine capable of flying in the atmosphere, including but not limited to tubular and winged aircraft, commercial transport aircraft, private jets, missiles, rotorcraft or unnamed aircraft. The system 20 may be used for the inlet or inlet of any component, including not only the propulsion engine 24 but also an auxiliary power unit (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com