Method for increasing extraction rate of pea separation protein

A technology of pea protein isolation and extraction rate, which is applied in plant protein processing, food preparation, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

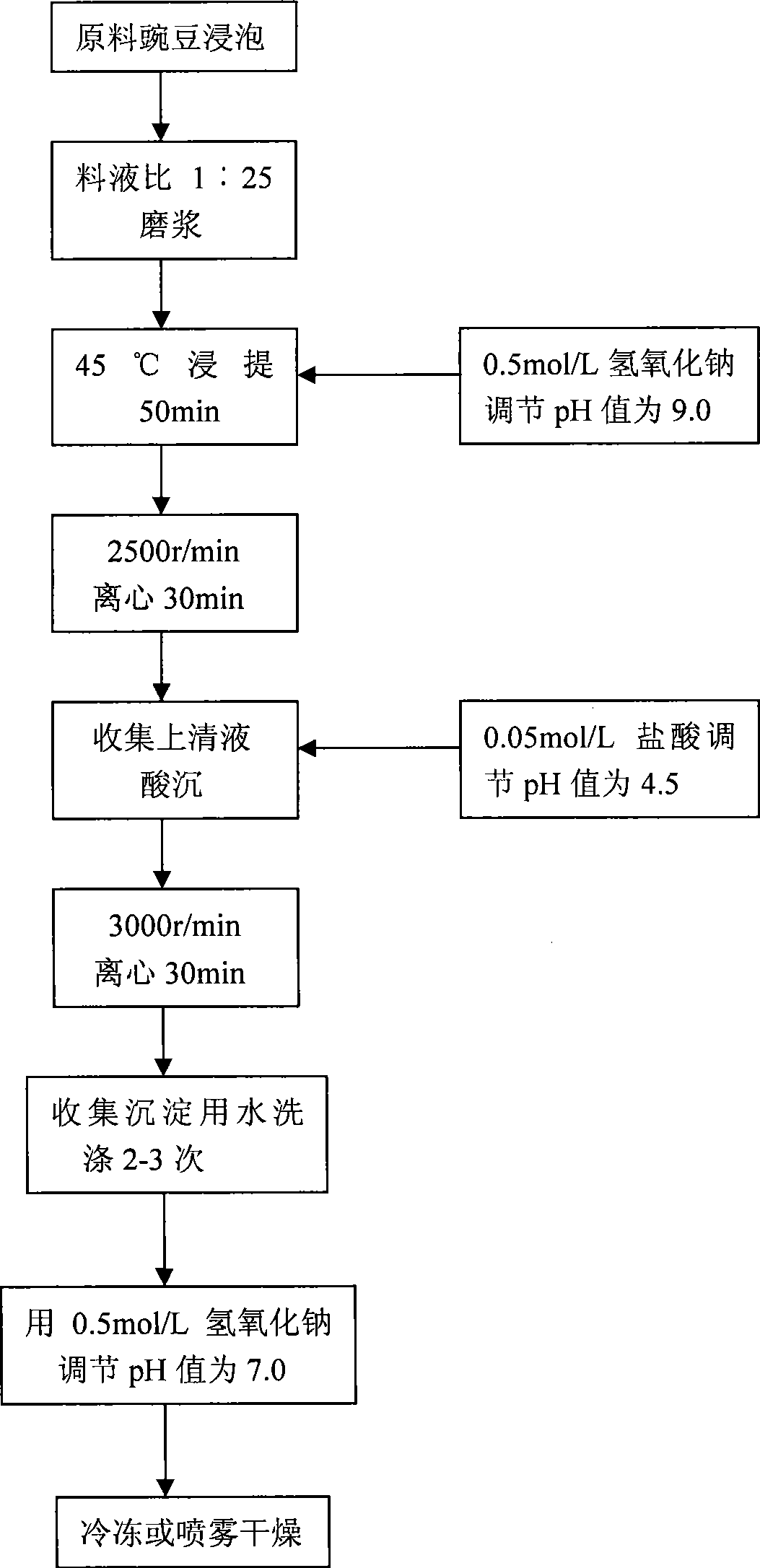

[0023] Embodiment 1: adopt single alkali-soluble acid precipitation process: take 2000 grams of peas, soak them in clear water for 6-7 hours, peel them, grind them with 1:25 water, adjust their pH value with 0.5mol / L sodium hydroxide 9.0, keep it in a water bath at 45°C for 50 minutes, and keep stirring. Then take out the feed liquid, centrifuge at 2500r / min for 30min, keep the supernatant, adjust the pH value to 4.5 with 0.05mol / L hydrochloric acid for acid precipitation. Then centrifuge at 3000r / min for 30min to obtain a precipitate, wash with water 2-3 times, and finally adjust its pH value to 7.0 with 0.5mol / L sodium hydroxide. Then freeze-dry to obtain pea protein isolate. Its protein extraction rate is 81.82% after testing, and the purity of the obtained pea protein isolate is 91.1%.

Embodiment 2

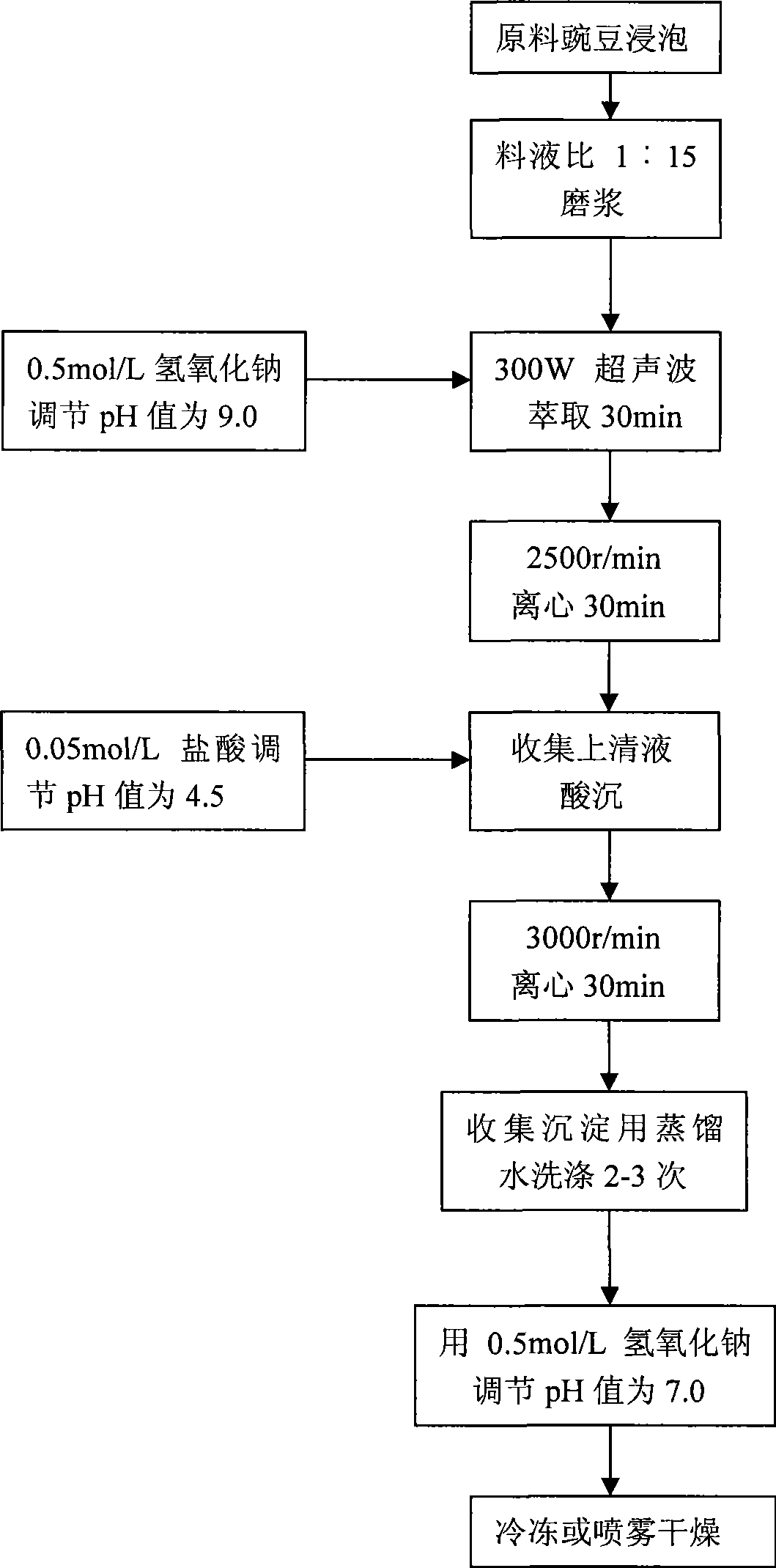

[0024] Embodiment 2: Ultrasonic-assisted alkali-dissolving acid precipitation process: Weigh 2000 grams of peas, soak them in water for 6-7 hours, peel them, grind them with 1:15 water, and adjust their pH with 0.5mol / L sodium hydroxide The value is 9.0, and the extraction is assisted under 300W ultrasonic conditions for 30min. Then take out the feed liquid, centrifuge at 2500r / min for 30min, keep the supernatant, adjust the pH value to 4.5 with 0.05mol / L hydrochloric acid for acid precipitation. Then centrifuge at 3000r / min for 30min to obtain a precipitate, wash with water 2-3 times, and finally adjust its pH value to 7.0 with 0.5mol / L sodium hydroxide. Then spray drying to obtain pea protein isolate. Its protein extraction rate was detected to be 83.50%, and the obtained pea protein isolate had a purity of 91.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com