Polymer producing method and apparatus and polymer degassing method and apparatus

A manufacturing method and a technology of polymers, which are applied in the field of polymer manufacturing, can solve problems such as poor devolatilization performance, lowered performance, and methods and devices that do not record the monomer removal process, and achieve the goal of suppressing coloring and suppressing residence time increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings, but the scope of the present invention is not limited thereto.

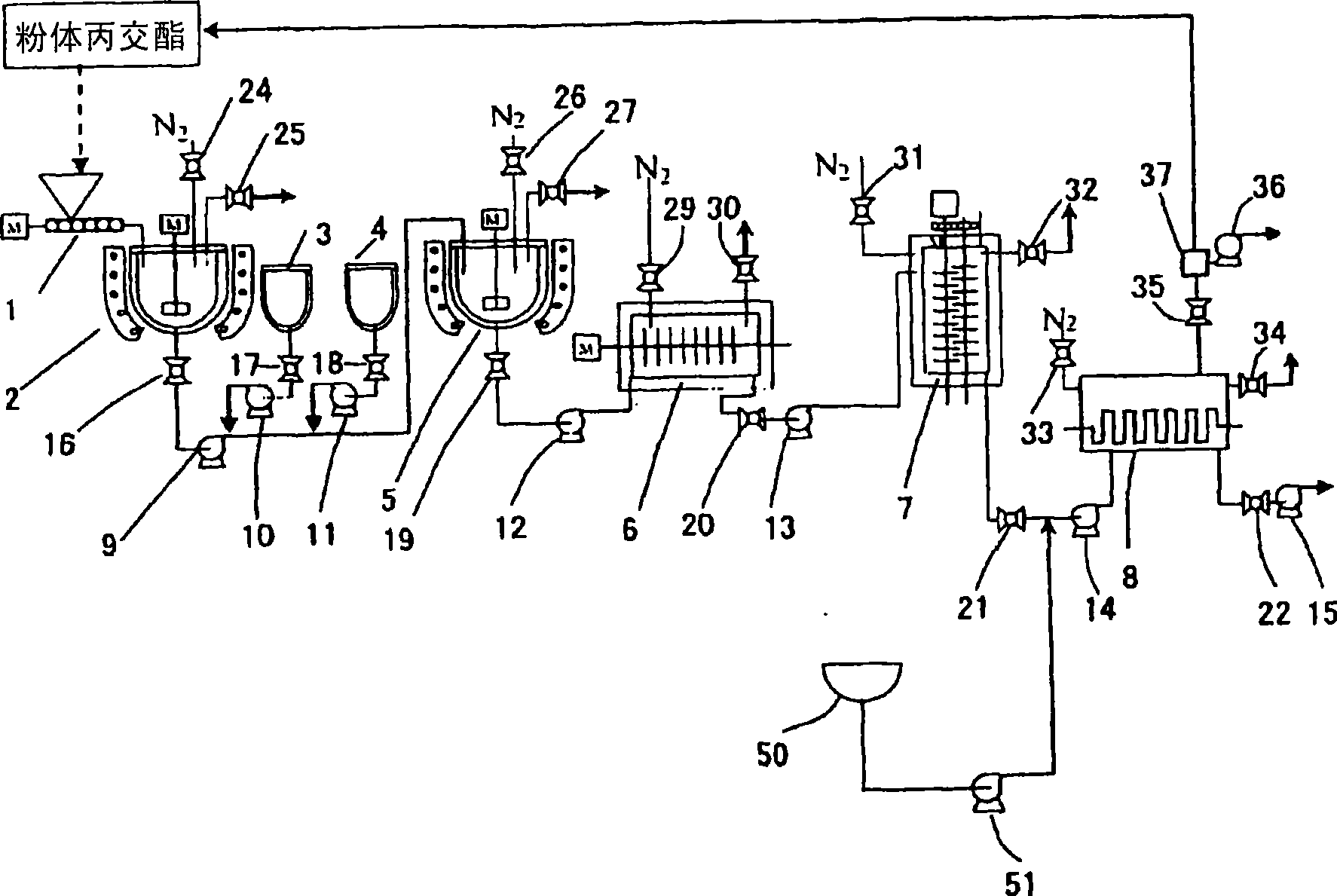

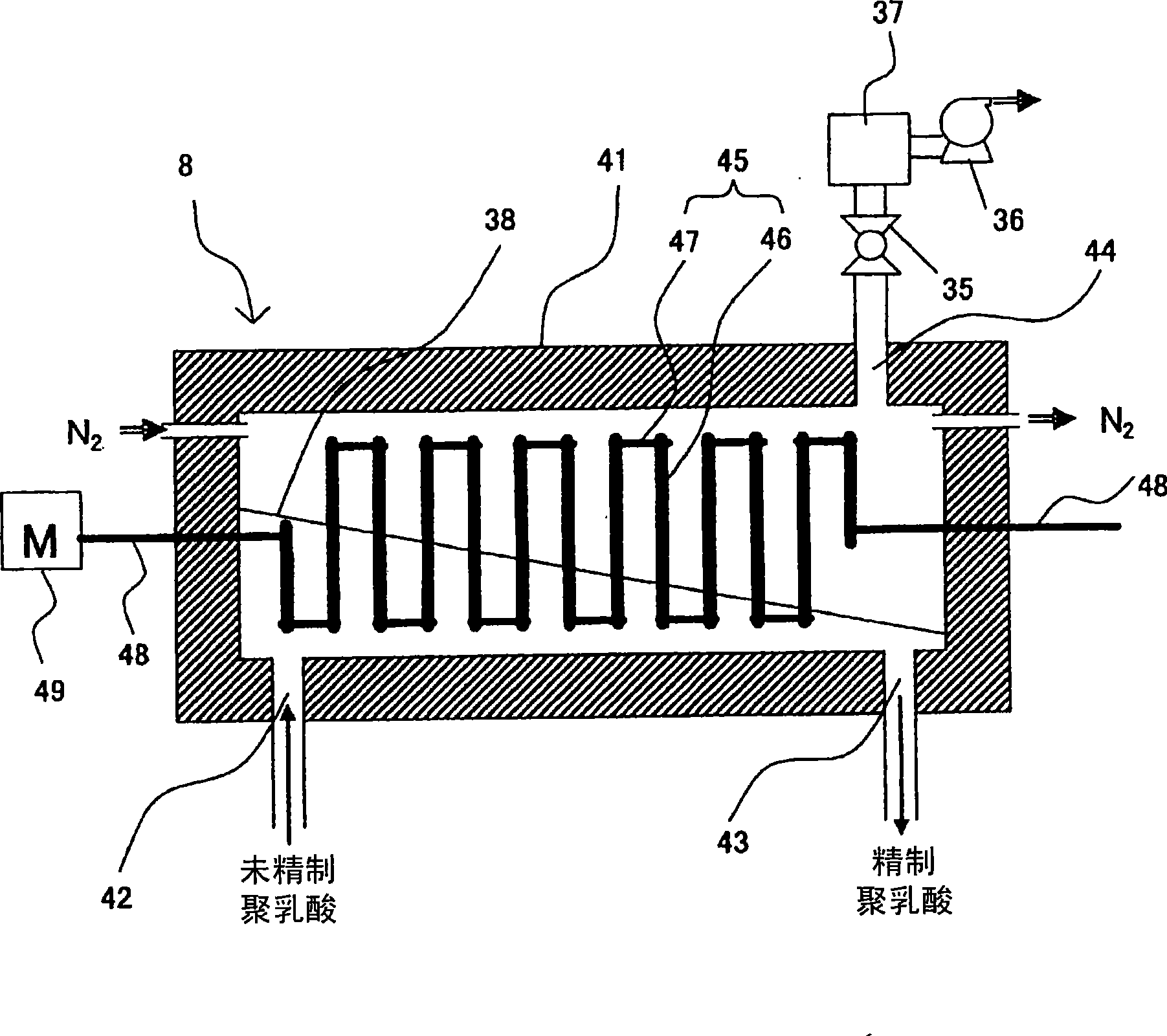

[0105] figure 1 It is an overall view explaining the production process of polylactic acid to which the present invention is applied. figure 2 It is a cross-sectional view of a devolatilization device to which polylactic acid of the present invention is applied.

[0106]The manufacturing process of the present example includes a reaction step of polymerizing polylactic acid to produce it, and a devolatilization step of subjecting polylactic acid polymerized by the reaction step to a devolatilization treatment. In the reaction process, a lactide supply device 1, a lactide melting device 2, a catalyst supply device 3, a polymerization initiator supply device 4, a lactide supply device 5, a horizontal reaction tank 6, and a vertical reaction tank are used. Polylactic acid was polymerized with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com