Heat pressing and sulfuration integrated method and device for natural fabric elastic material

A technology of natural fibers and elastic materials, used in fiber processing, textiles and papermaking, etc., can solve problems such as unsatisfactory use effects, and achieve the effects of reducing heat energy consumption, reducing shape deviation, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

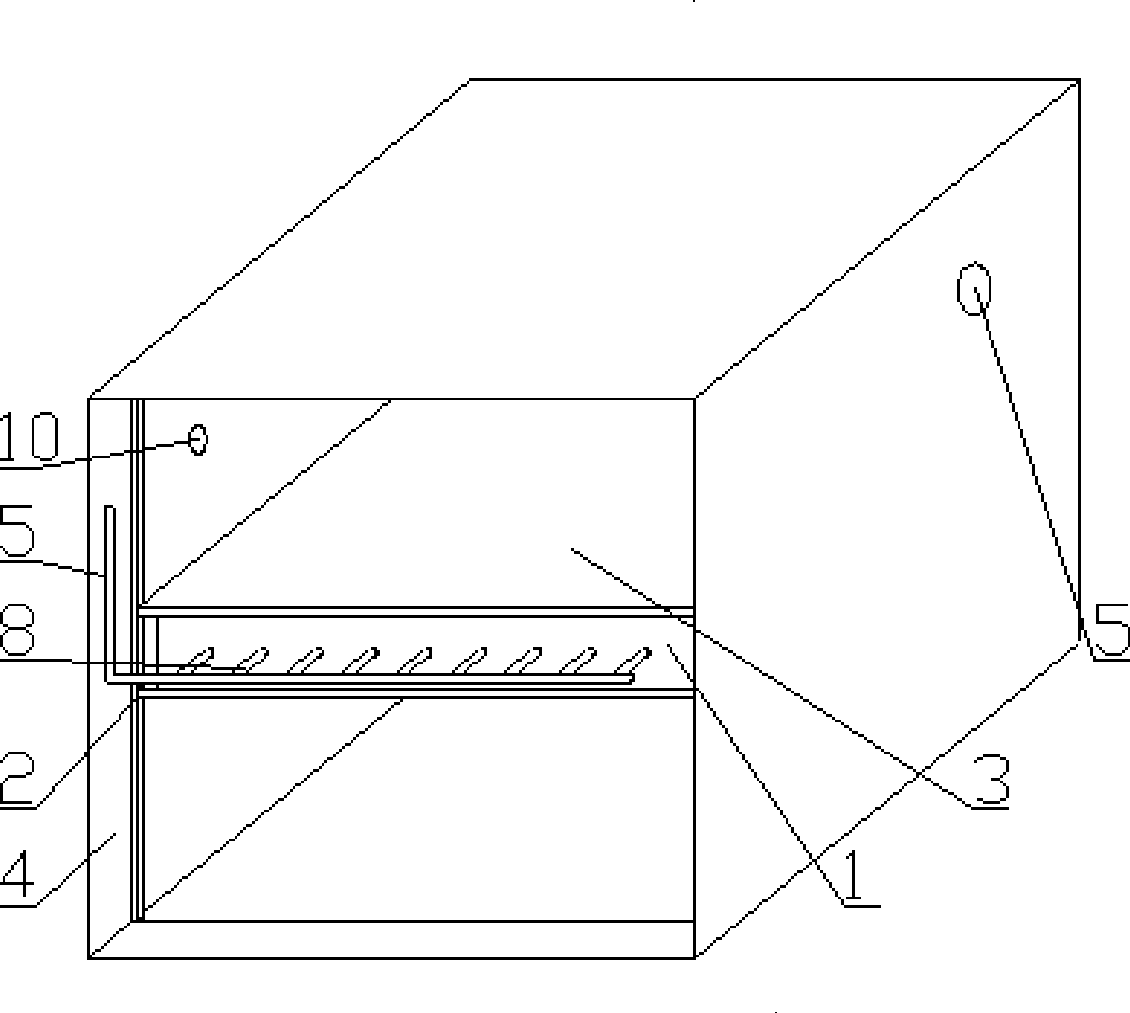

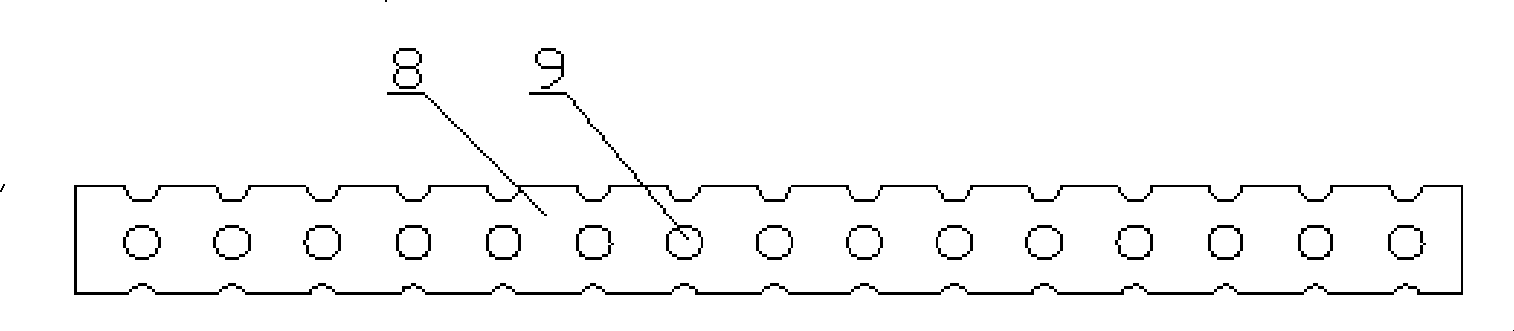

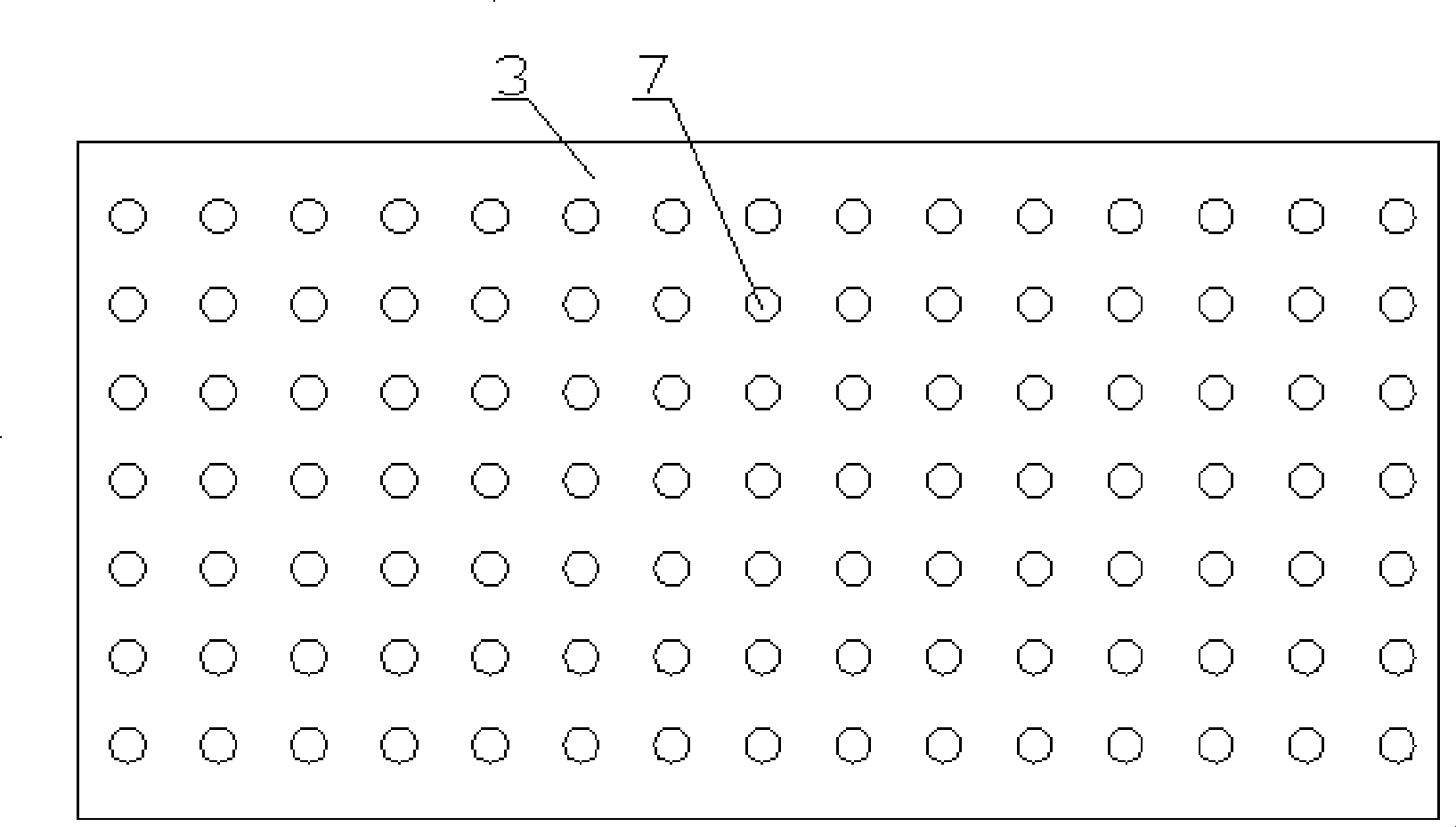

[0019] Embodiment of the present invention: can adopt existing heat-pressing rack structure, install hot-pressing plate 3 on hot-pressing rack 2, make heat preservation chamber 4 outside heat-pressing frame 2 then, heat-breathing chamber 4 is provided with hot-air duct 5 and exhaust Fan 6, hot air duct 5 blows hot air into for heating and vulcanization, and exhaust fan 6 discharges hot air after hot pressing and vulcanization. In order to improve heat conduction efficiency, holes 7 are provided in the heat press plate 3 . And in the middle of the natural fiber sheet 1, a ventilation pipe 8 is installed, the ventilation pipe 8 is connected with the hot air duct 5, micropores 9 are made on the ventilation pipe 8, and the ventilation pipe 8 provides heat to the inside of the natural fiber sheet 1, thereby improving thermal efficiency and vulcanization efficiency . A temperature sensor 10 is installed in the heat preservation chamber 4 for monitoring the temperature of the heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com