Counter weight control construction method for large span un-symmetric segment stayed-cable bridge

A construction method and technology for cable-stayed bridges, applied in cable-stayed bridges, bridges, bridge forms, etc., can solve problems such as tower top offset, inability to better control beam alignment, etc., so as to correct tower offset and reduce construction. effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

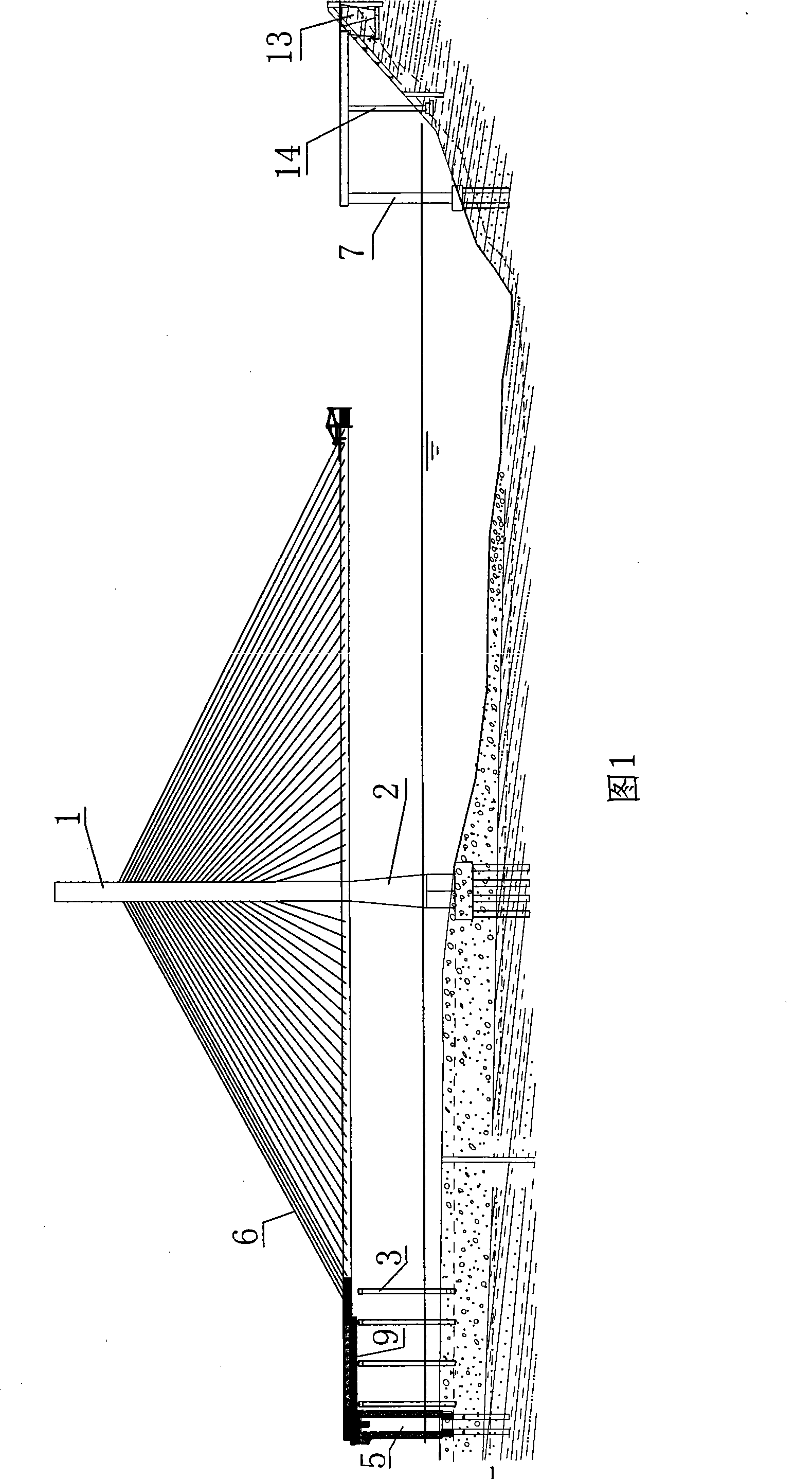

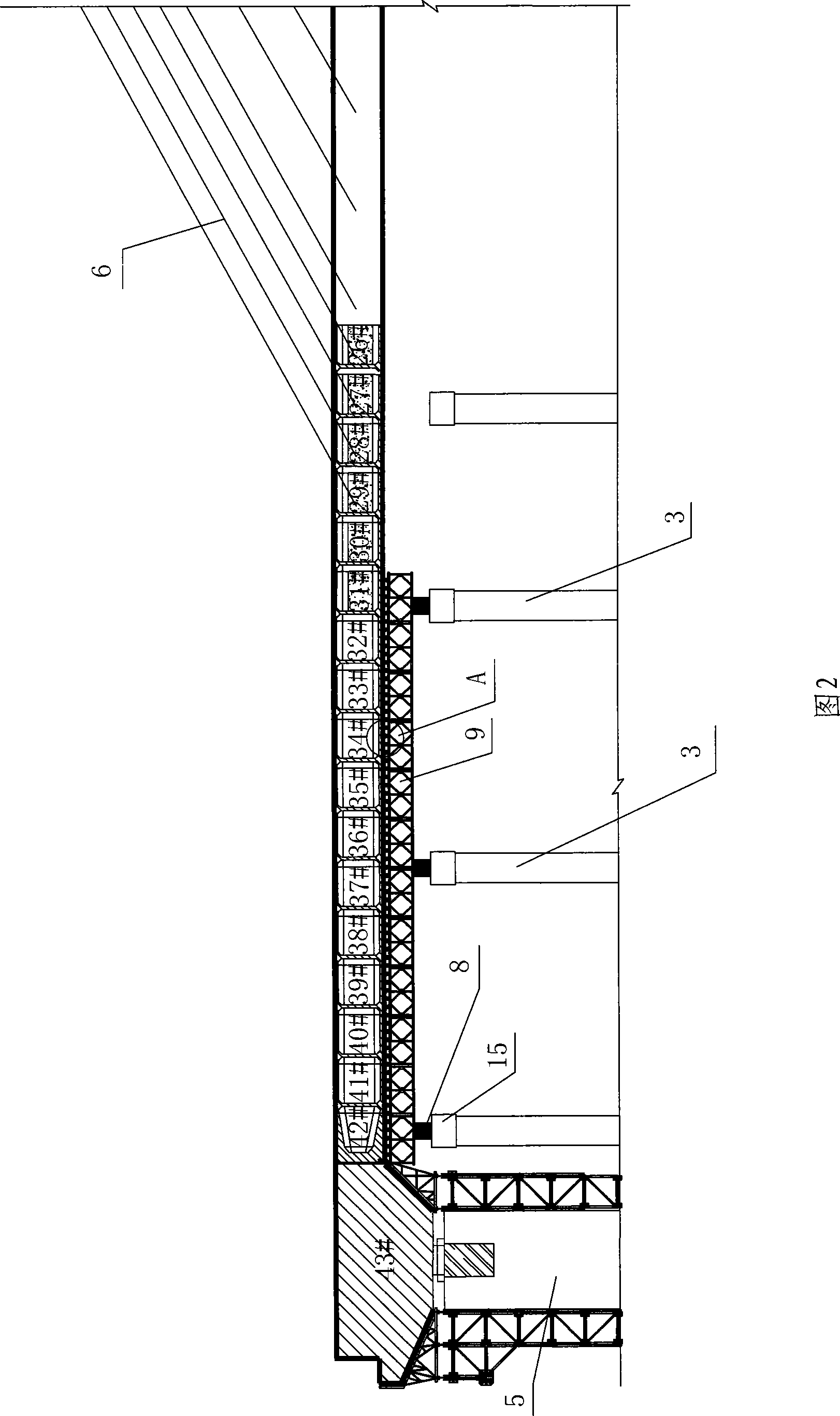

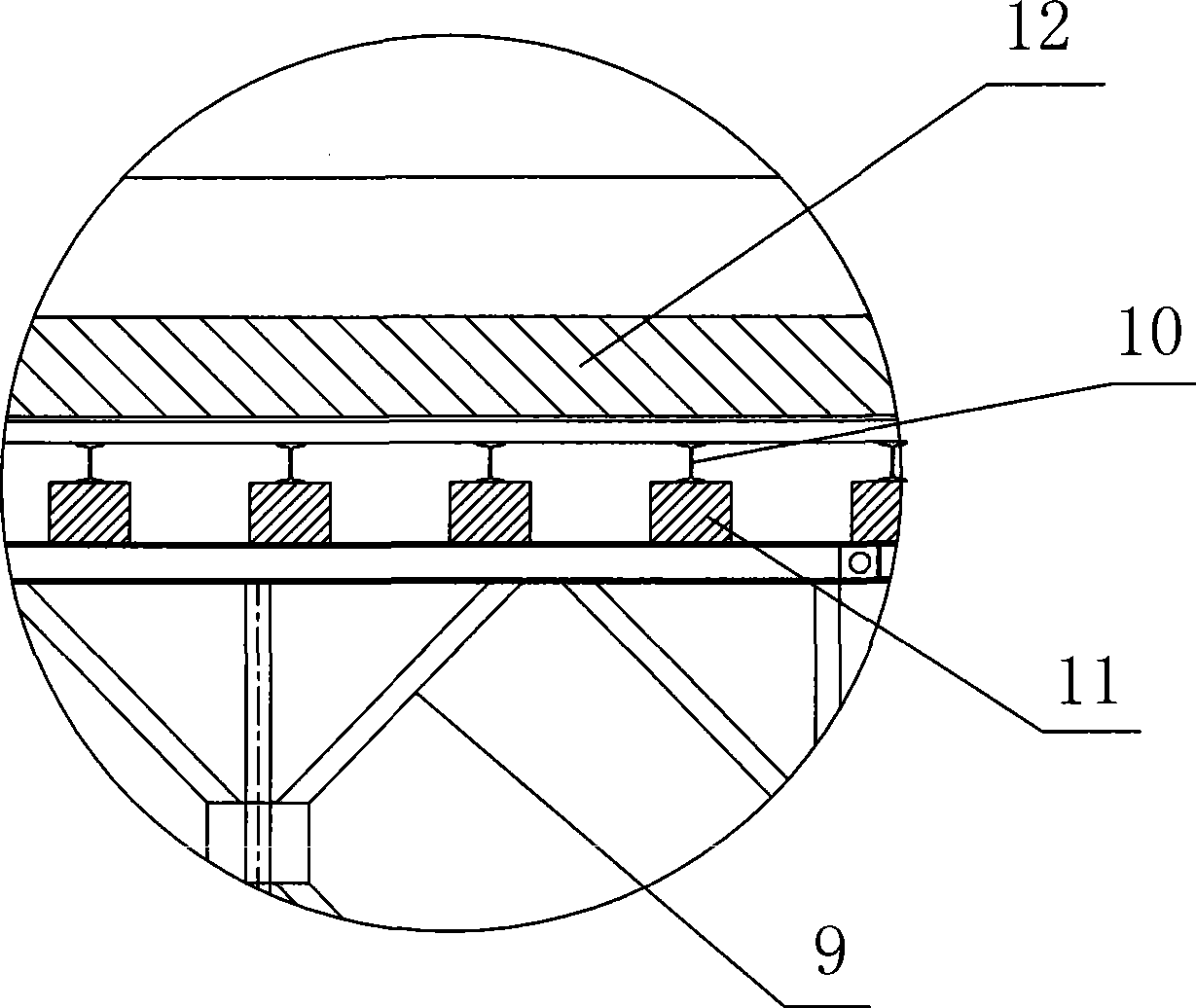

[0033] As shown in Figure 1 and Figure 2, the large-span asymmetric section cable-stayed bridge constructed by the present invention is a single-tower double-cable-plane asymmetric reinforced concrete cable-stayed bridge, and the hole-span arrangement position of this cable-stayed bridge is 208m+270m+35m +30m and its main span is 270m. That is to say, the distance between the cable tower 1 arranged on the side span pier and the left side span side pier 5 is 208m, and the distance between the cable tower 1 and the right main span side pier 7 is 270m. The distance between the main span side pier 7 and the abutment 13 on the right side is 35m+30m, and a pier 14 is also arranged between the main span side pier 7 and the abutment 13, between the main span side pier 7 and the abutment 14 The distance between the pier 14 and the abutment 13 is 30m. The main span beam section that has been constructed has been erected between the main span side pier 7 and the abutment 13, and the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com