Air spring test stand

A technology of air spring and test bench, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc. It can solve the problems of irregular shape and high weight, and achieve stability and safety. , The effect of simplifying the structure of the test bench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

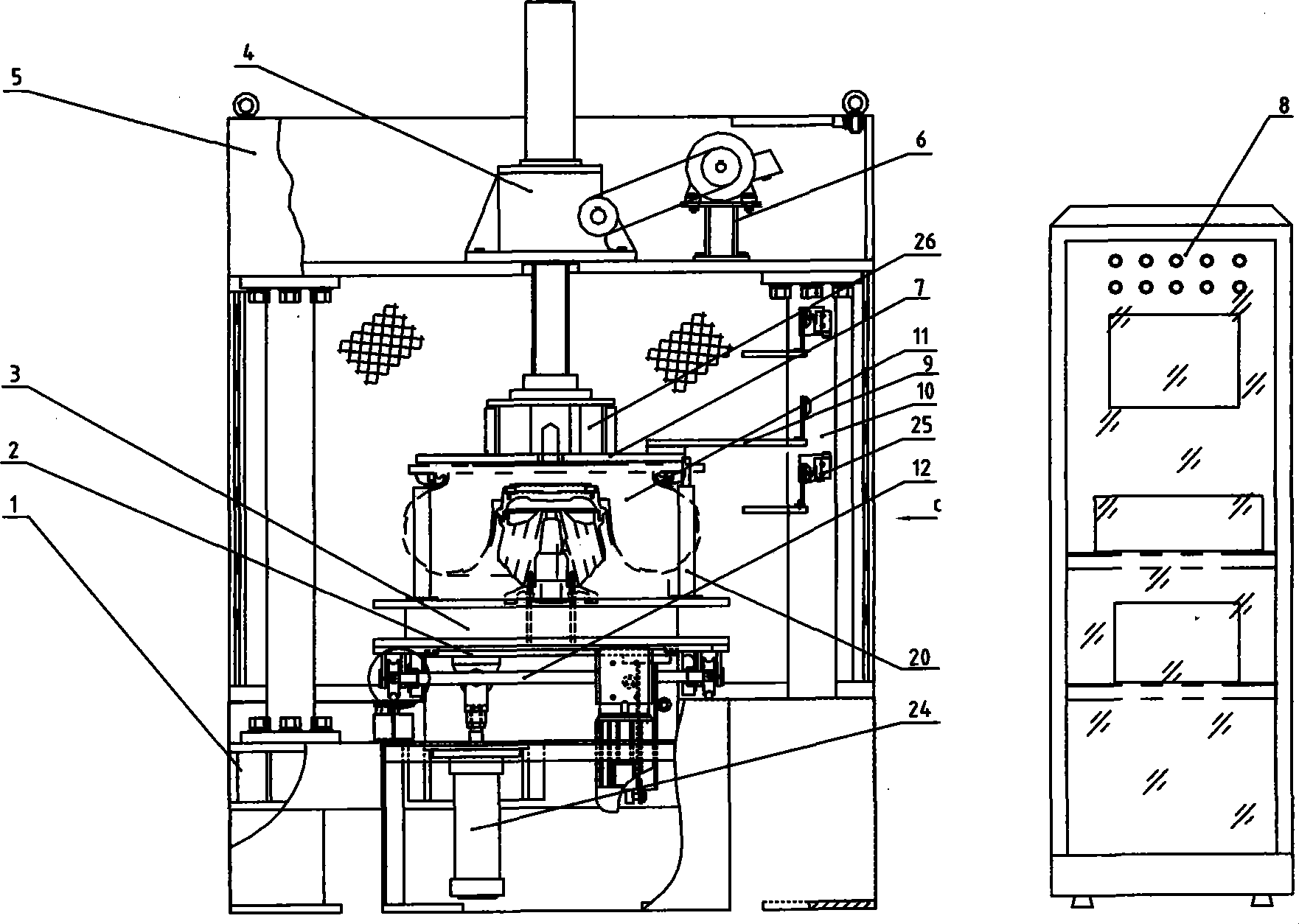

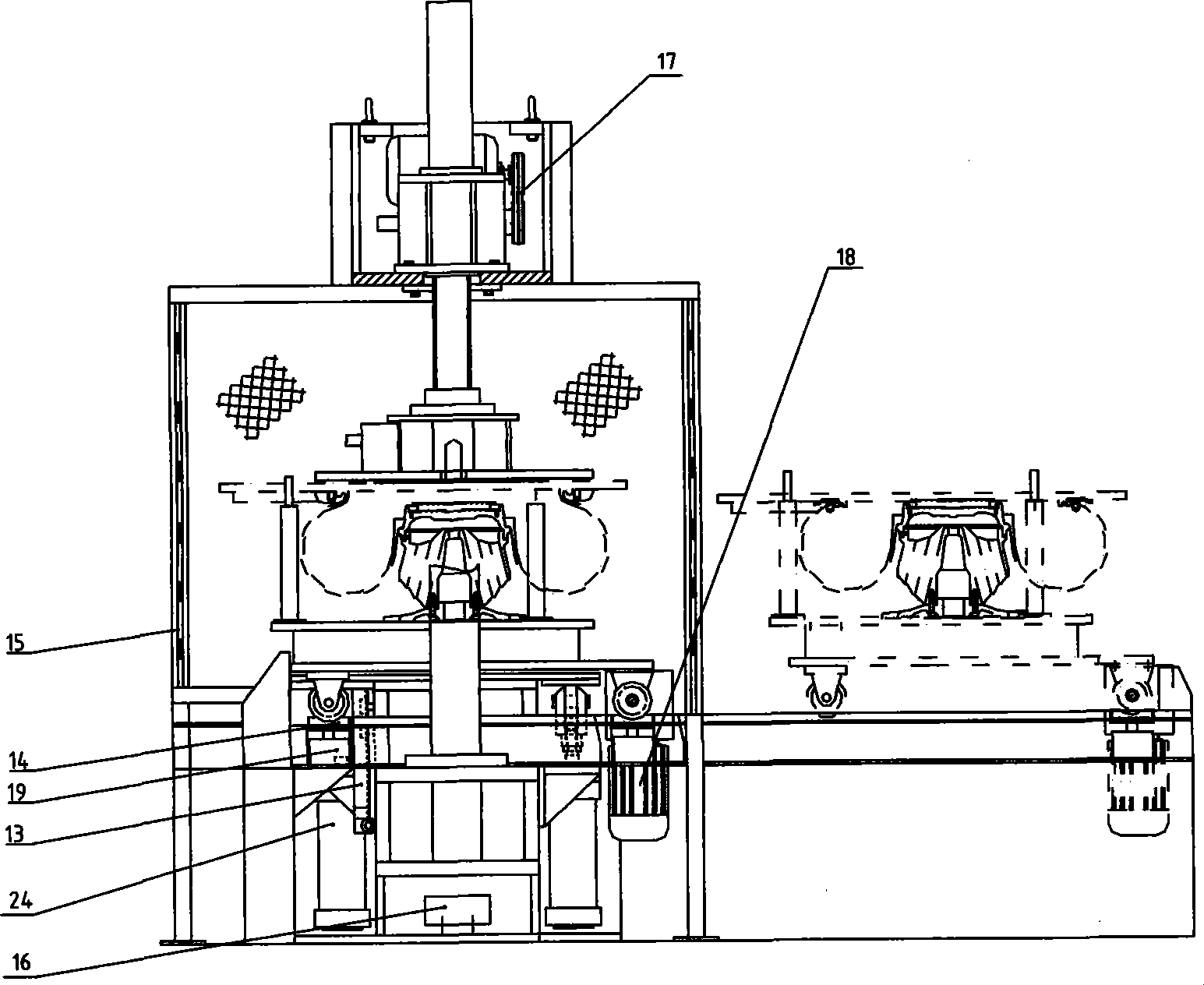

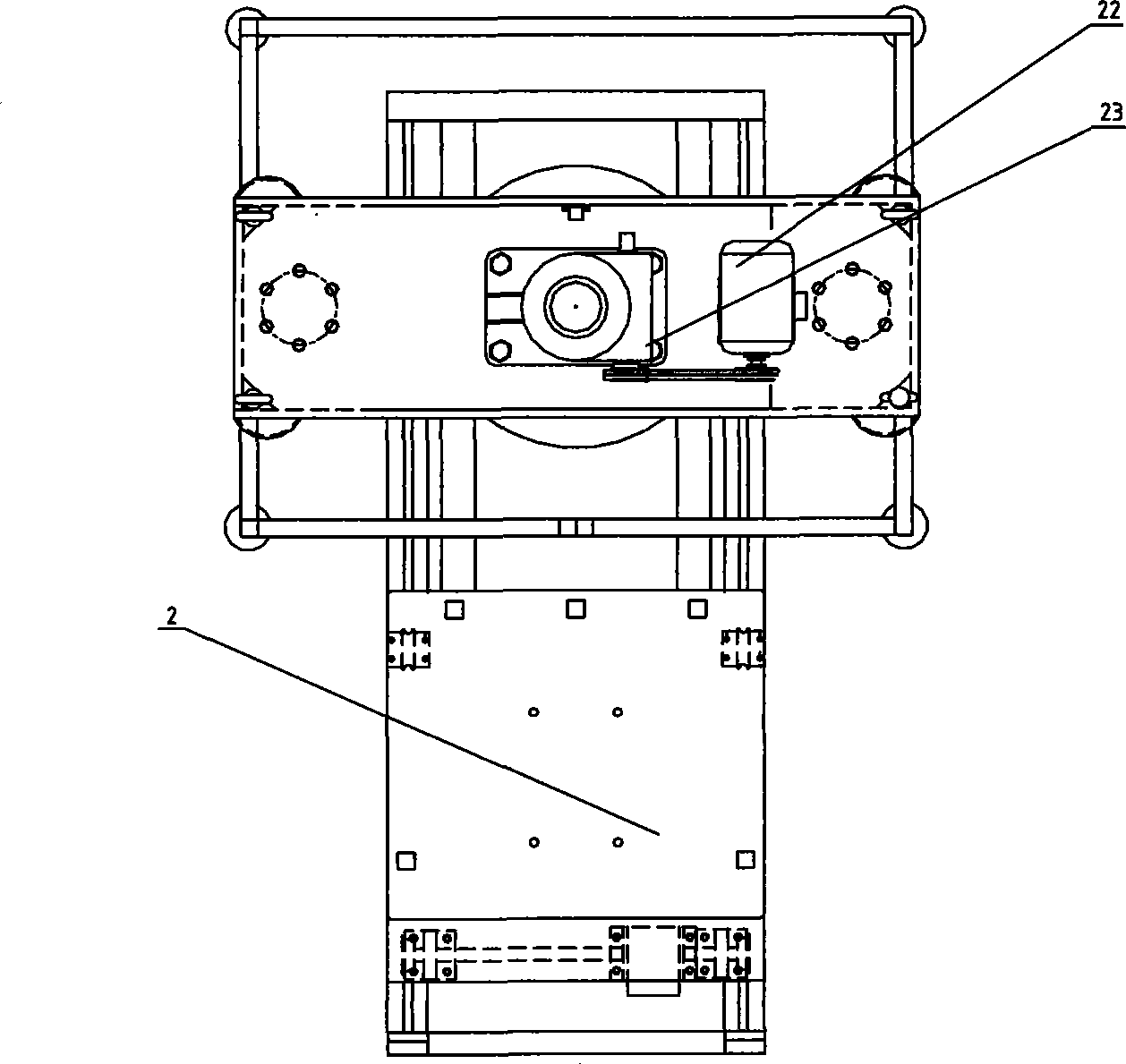

[0026] An air spring test bench, including a mechanical system, a pneumatic system, and an electrical measurement and control system, the electrical measurement and control system detects and controls the state of the mechanical system and the pneumatic system, the mechanical system includes a workbench, and a safety guardrail 15 is arranged on the workbench , The bottom of the workbench is provided with a lifting device 2, the lower beam composition 1 at the bottom is provided with a carrying device 3, and one side of the workbench column composition 10 is equipped with an air inflation mechanism. A loading screw mechanism 4 is installed on the beam 5 at the top of the workbench, and the loading screw mechanism 4 is located directly above the lifting device 2; wherein, a pressure sensor 31 is arranged in the air duct connecting the air inflation mechanism and the tested air spring 11, The column 10 is provided with a displacement sensor 21 for measuring the displacement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com