Quantum dot light emitting devices

A technology of electroluminescent element and manufacturing method, which is applied to the manufacturing of electroluminescent light sources, electrical components, semiconductor/solid-state devices, etc. Life characteristics, effect of improving light emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

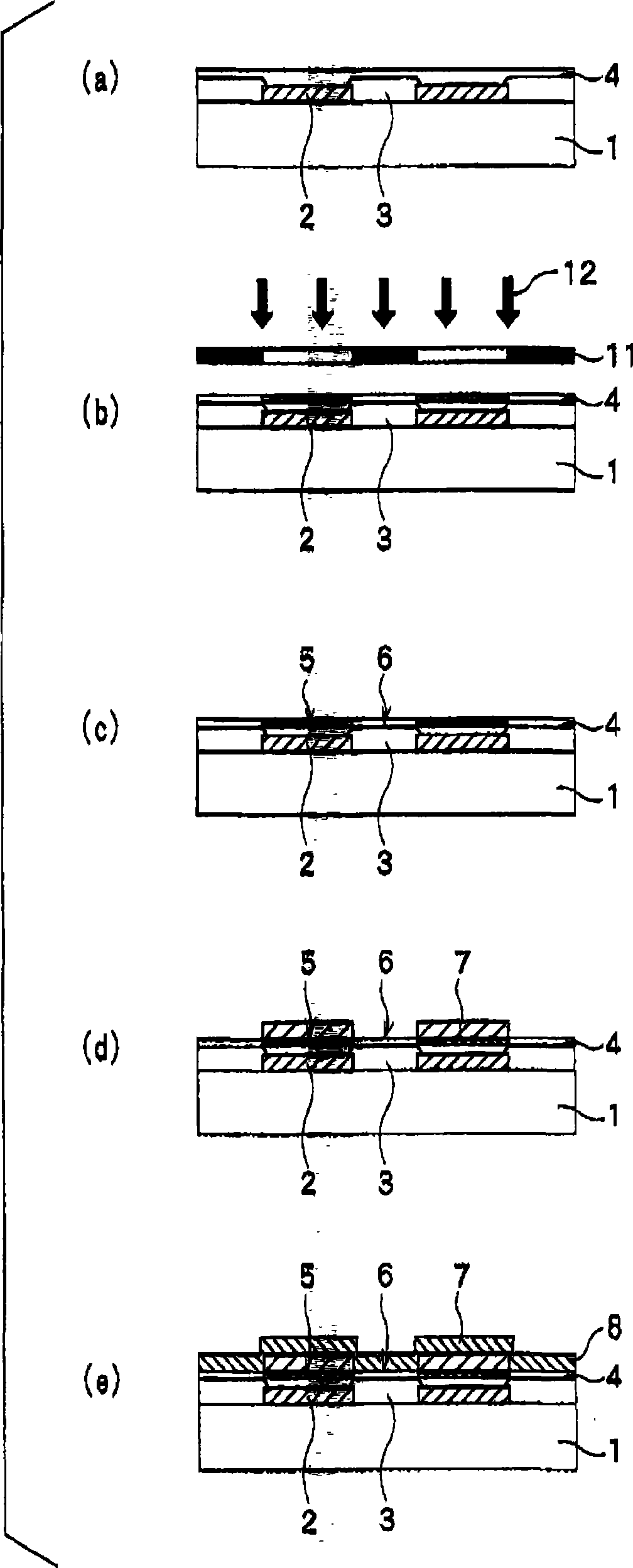

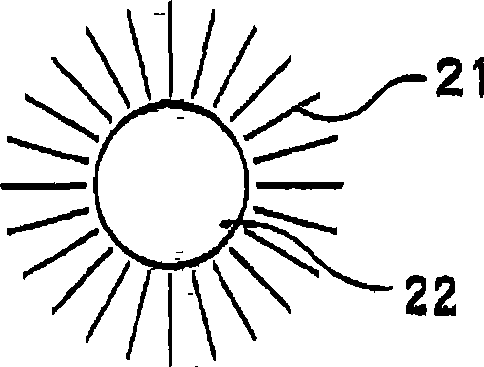

[0055] The first embodiment of the manufacturing method of the EL element of the present invention is characterized in that it includes the following steps: a wettability changing layer forming step of forming a wettability layer containing a photocatalyst on the substrate on which the first electrode layer is formed. The wettability changing layer whose properties are changed by the action of the photocatalyst accompanied by energy irradiation; the wettability changing pattern forming step, by irradiating the above wettability changing layer in a pattern shape, the above wettability changing layer A wettability change pattern consisting of a lyophilic region and a liquid-repellent region is formed on the surface; a light-emitting layer forming step is to apply a coating for forming a light-emitting layer containing quantum dots with ligands arranged around it on the above-mentioned lyophilic region. Distribute the liquid to form a luminescent layer.

[0056] A method of manuf...

no. 2 Embodiment approach

[0334] The second embodiment of the manufacturing method of the EL element of the present invention is characterized in that it includes the step of forming a wettability variable layer on the substrate on which the first electrode layer is formed, forming a wettability factor accompanying energy irradiation. The wettability changing layer changed by the action of the photocatalyst; the wettability changing pattern forming process, relative to the above wettability changing layer, vacates the gap that can be affected by the action of the catalyst accompanying energy irradiation, and arranges it on the substrate. A photocatalyst treatment layer substrate having a photocatalyst treatment layer containing at least a photocatalyst is formed, and then, by irradiating energy in a pattern, a wettability region consisting of a lyophilic region and a liquid repellent region is formed on the surface of the wettability changing layer. Moisture change pattern; light emitting layer forming ...

Embodiment 1

[0482] (Formation of transparent electrodes)

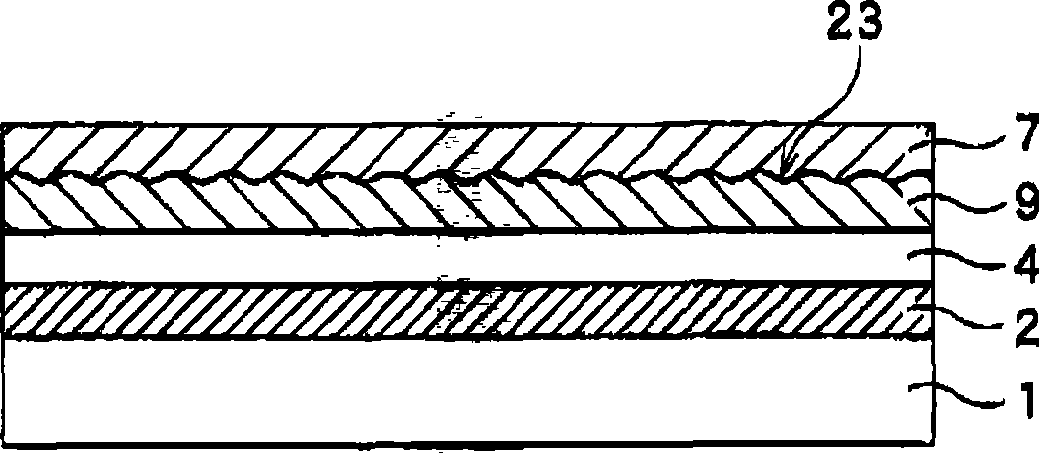

[0483] On the cleaned glass substrate, use sputtering method to 1500 The film thickness forms an ITO film as a transparent electrode. Then, the ITO film was patterned with a line width of 300 μm and a space of 100 μm by photolithography.

[0484] (Formation of insulating layer)

[0485] A negative resist (manufactured by Nippon Steel Chemical Co., Ltd., V259PA) was applied by spin coating to a dry film thickness of 1 μm on the substrate on which the ITO film was patterned, and then baked at 120° C. for 1 hour. Then, a 365-nm UV light was exposed at an exposure amount of 500 mJ through a photomask with a width of 100 μm centering on the space portion without the ITO film. At this time, exposure was performed with a gap of 1 mm between the photomask and the substrate. This was developed for 40 seconds using an organic alkali developer (manufactured by Nippon Steel Chemical Co., Ltd., V259OD), and then baked at 160° C. for 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com