Method for the continuous production of unsaturated carboxylic acid anhydrides

An unsaturated, carboxylic acid anhydride technology, applied in the direction of carboxylic acid anhydride preparation, chemical instruments and methods, carboxylate preparation, etc., can solve the problem that by-products cannot be completely removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

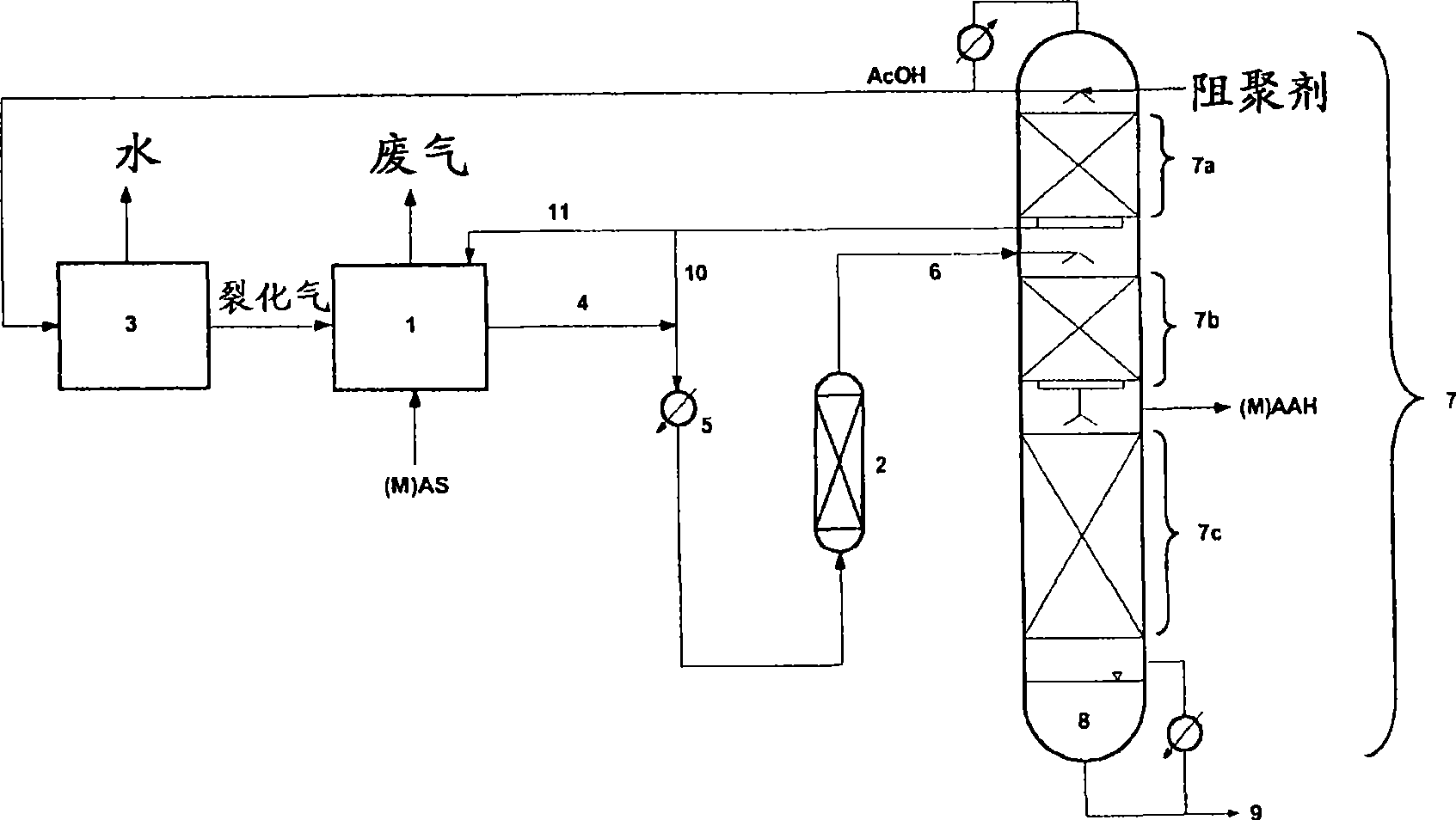

[0059] The preparation of ketene (3) is carried out according to a conventional method. A detailed description of the preparation of ketene is contained, for example, in H. Held, A. Rengstl and D. Mayer, Acetic anhydride and mixed fatty acid anhydrides, Ullmann's Encyclopedia of Industrial Chemistry, 6th edition, Wiley VCH, Weinheim, 2003, pp. 184-185 Page.

[0060] The following reaction of ketene with (meth)acrylic acid (=(M)AS) in reaction zone (1) is likewise carried out according to conventional methods (see also H. Held et al., p. 185ff.). At this point the crude anhydride mixture (4) is fed into a further reaction zone (2). The temperature of reactant can be adjusted through heat exchanger (5) during adding.

[0061] Reactor (2) is preferably a flow tube reactor containing a fixed bed catalyst. As fixed-bed catalysts, preference is given to using acidic ion exchangers.

[0062] The reactor waste stream (6) is fed into a rectification column (7), preferably in the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com