Brake discs excellent in resistance to temper softening and toughness

A brake disc, excellent technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of high cost, reduced hardness, expensive manufacturing cost of brake discs, etc., and achieve high temper softening resistance, Excellent temper softening resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

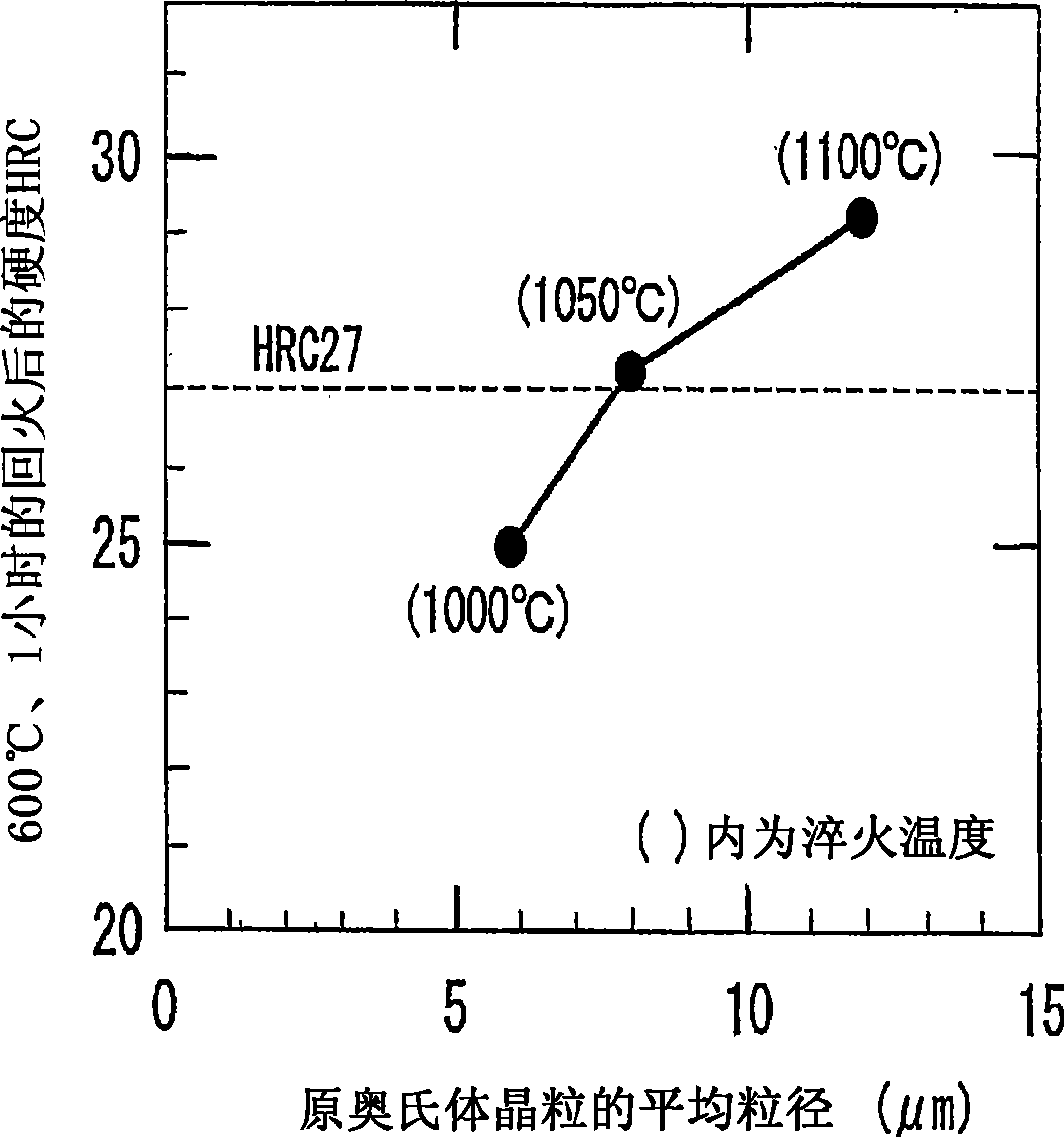

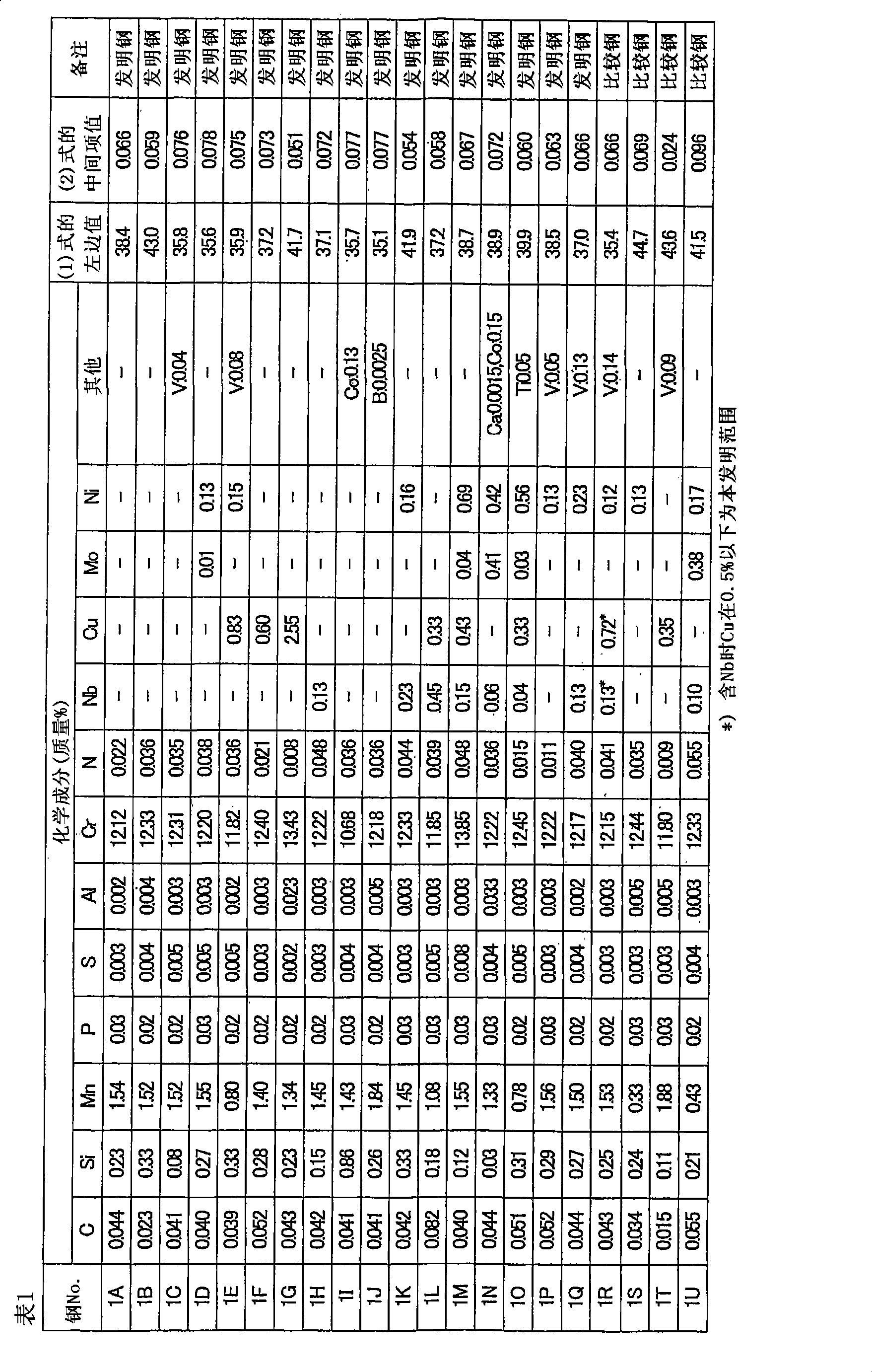

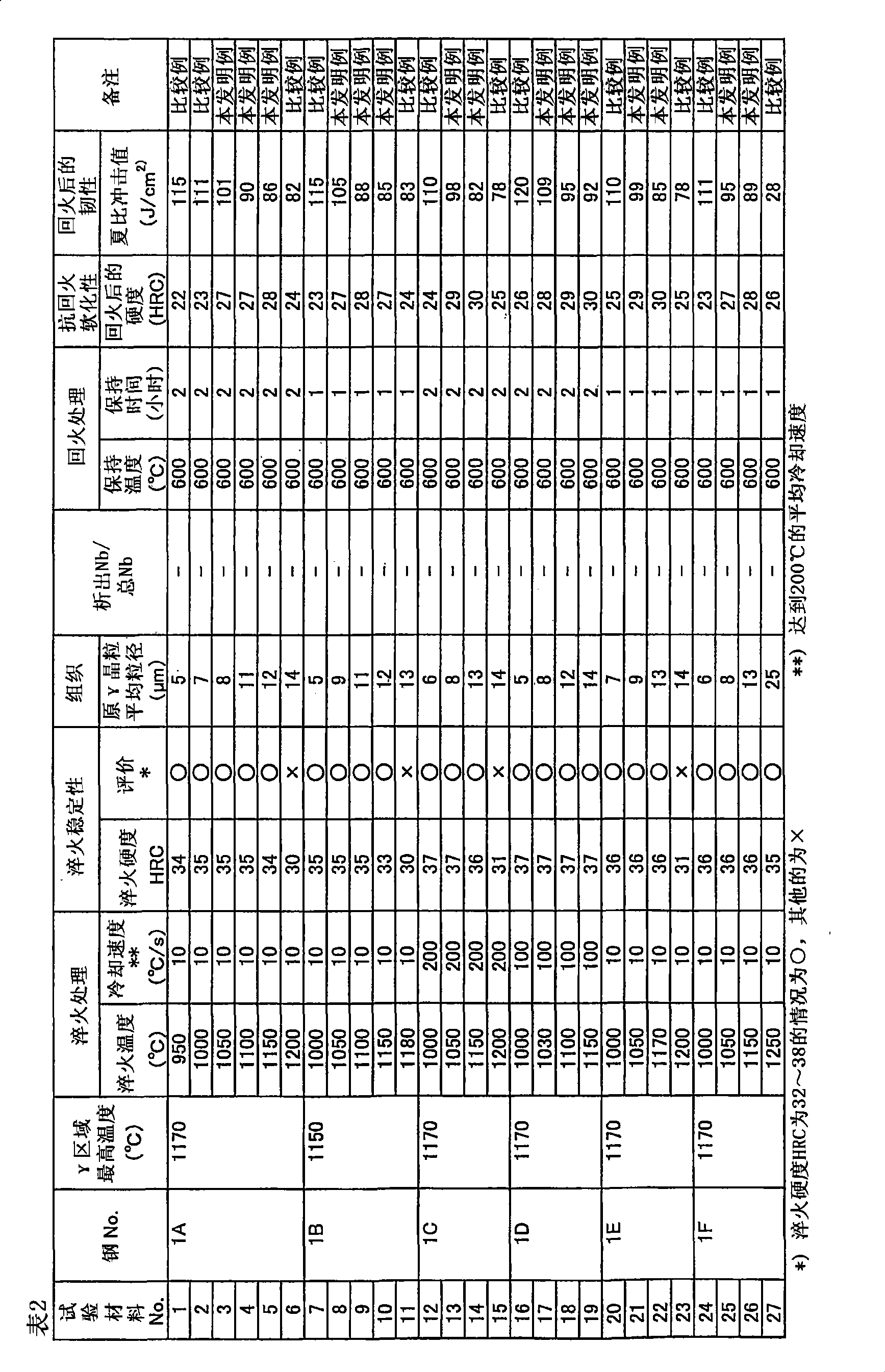

[0105] Molten steel with the composition shown in Table 1 was melted in a high frequency melting furnace (high frequency melting furnace), and cast into steel raw materials. Next, these steel raw materials were made into a hot-rolled steel plate (plate thickness: 5 mm) by normal hot rolling. Further, these hot-rolled steel sheets were subjected to hot-rolled sheet annealing at 800° C. for 8 hours (reducing gas (reducing gas) atmosphere, heating followed by gradual cooling). Next, these hot-rolled steel sheets are subjected to pickling treatment to remove scale on the surface, thereby producing raw materials for brake discs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com