Mixing roll for treating fecal of livestock and poultry

A technology of livestock and poultry manure and mixing machines, applied in the field of mixing machinery, can solve the problems of polluting the environment, not being easy to clean, and not being able to effectively deal with the adhesion and agglomeration of mixtures, and achieve the effect of not polluting the environment and being easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

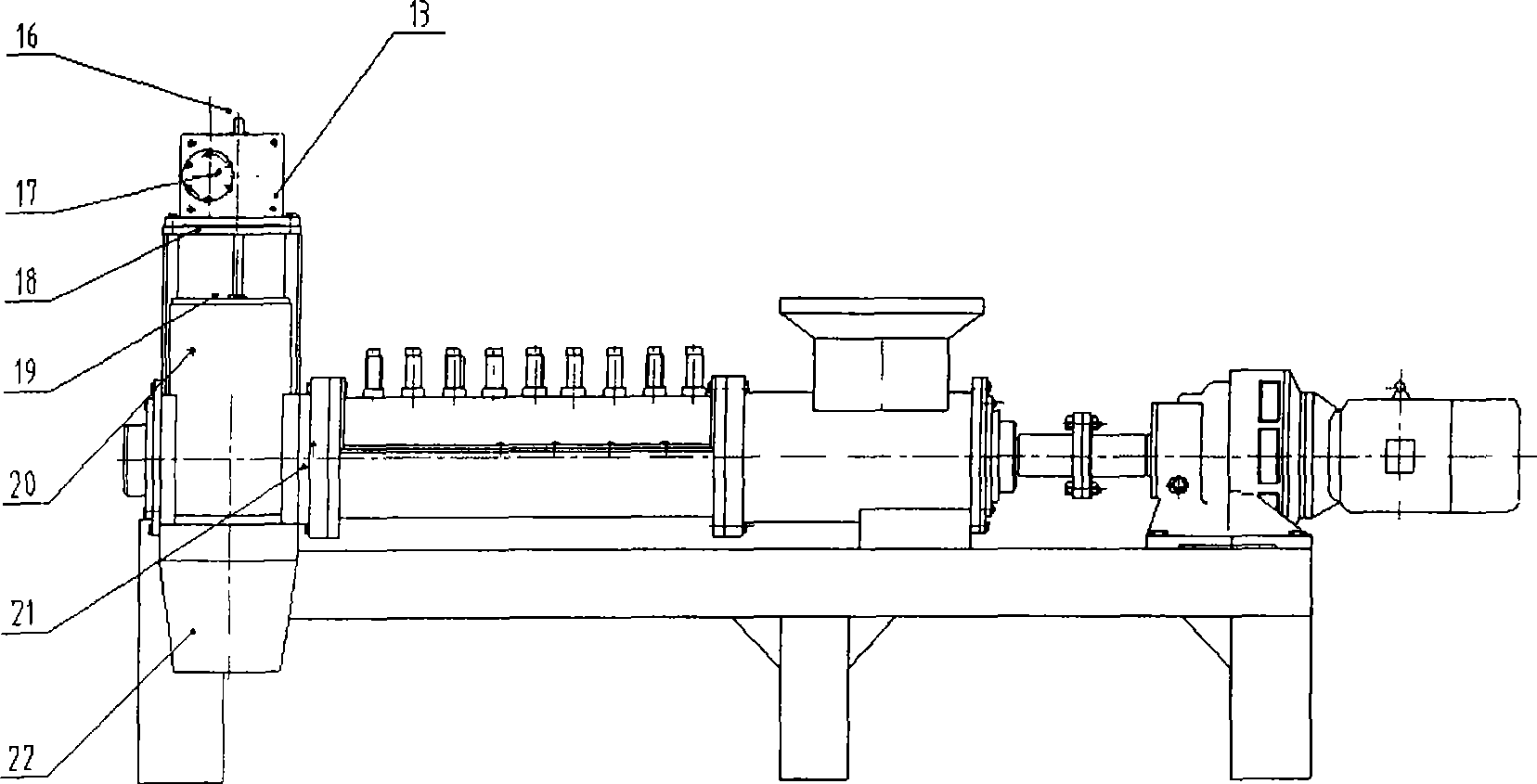

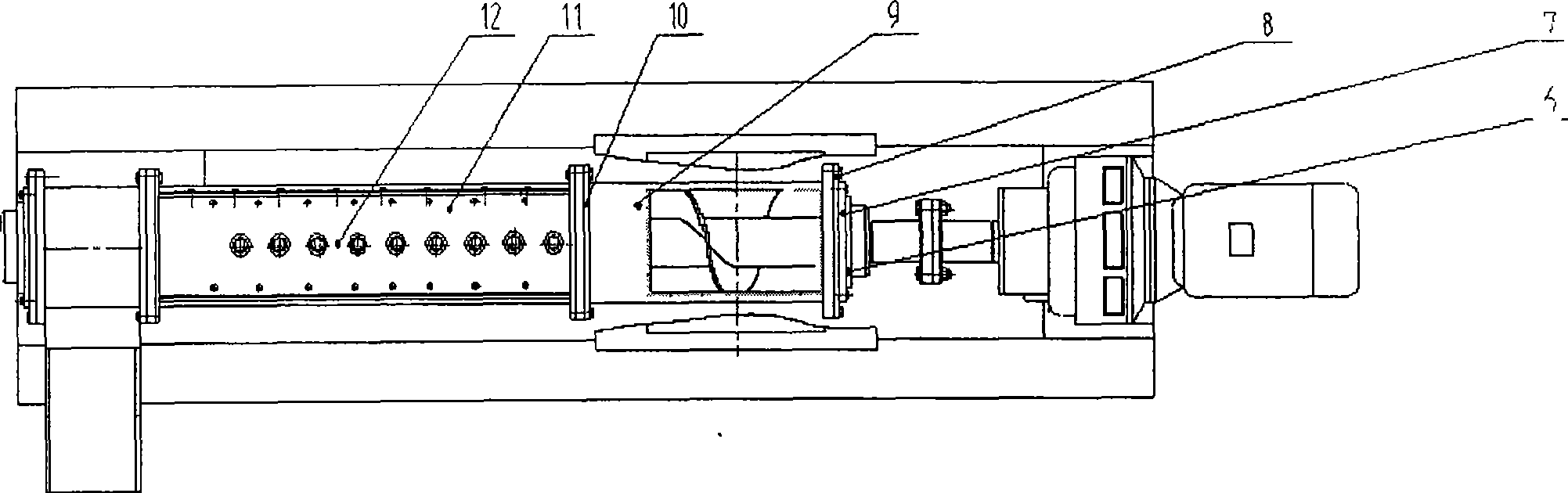

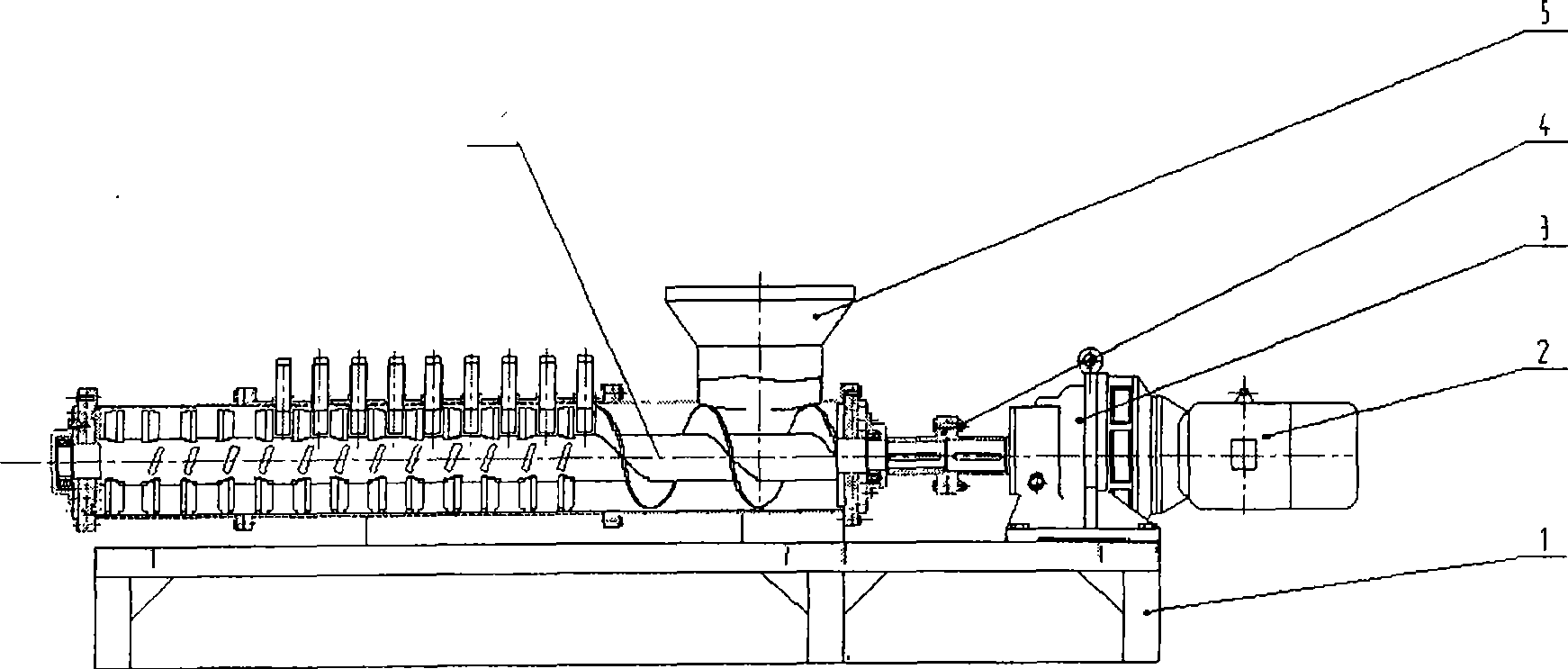

[0012] The livestock and poultry excrement treatment mixing machine of the present invention consists of a frame (1), a main motor (2), a reducer (3), a shaft coupling (4), a feeding hopper (5), a front bearing seat (6), a partition Plate (7), connecting flange (8), feeding barrel (9), mixing barrel (10), mixing barrel cover (11), adjusting lever (12), discharging machine (13), stirring Baffle plate (14), stirring rod (15), lead screw (16), discharge reducer (17), top plate (18), top sleeve (19), valve plate (20), guide rail (21), material receiving Port (22), main shaft (23), rear bearing seat (24), mixing casing (25), discharge motor (26), and propulsion screw blade (27); the mixing machine is integrally installed on the frame (1 ), the main motor (2) is connected to the main shaft (23) through the reducer (3), the coupling (4), and the main shaft (23) is composed of the front bearing seat (6), the rear bearing seat (24) and the mixer The shells (25) are matched and assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com