Preparation method of modified comet fiber filtering material

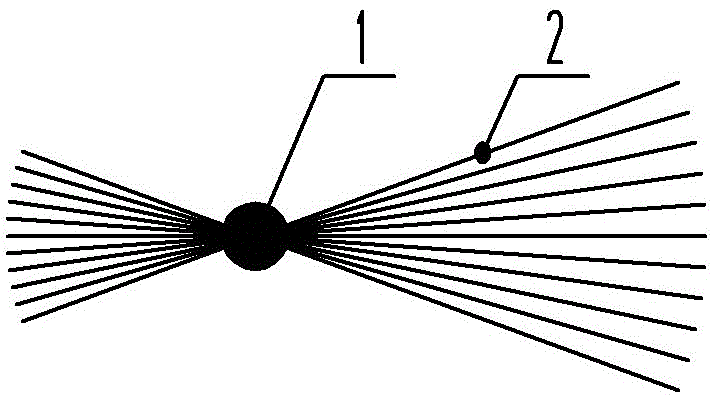

A fiber filtration and comet technology, which is applied in the field of preparation of new oil removal filter materials, can solve the problems of poor filtration effect, small fiber porosity, uneven large pores, etc., and achieves good elasticity, excellent filtration accuracy, lipophilic and hydrophobic high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the modified comet fiber filter material of the present invention comprises the steps of spinning polyester fiber raw materials, the step of converging the polyester fiber filaments, the step of injecting the polyester fiber filament bundles into briquettes, and briquetting the polyester fiber filament bundles Cutting off to form the step of comet type fiber filter material also includes the following steps:

[0029] (1) Put the mechanically processed comet-type fiber filter material into the washing tank, and after stirring for 1-2 minutes, rinse the silicone oil on its surface with clear water, then remove and control the water for later use;

[0030] (2) Put 2% (volume percentage) of viscose oil, 1.5% (volume percentage) of silicone oil and the rest into a container and stir evenly; then close the autoclave outlet valve and open the autoclave. The inlet valve is used to input the configured medicinal liquid and medicinal liquid pump into the...

Embodiment 2

[0034] The preparation method of the modified comet fiber filter material of the present invention comprises the steps of spinning polyester fiber raw materials, the step of converging the polyester fiber filaments, the step of injecting the polyester fiber filament bundles into briquettes, and briquetting the polyester fiber filament bundles Cutting off to form the step of comet type fiber filter material also includes the following steps:

[0035] (1) Put the mechanically processed comet-type fiber filter material into the washing tank, and after stirring for 1-2 minutes, rinse the silicone oil on its surface with clear water, then remove and control the water for later use;

[0036](2) Put 2% (volume percentage) of viscose oil, 1.5% (volume percentage) of silicone oil and the rest into a container and stir evenly; then close the autoclave outlet valve and open the autoclave. The inlet valve is used to input the configured medicinal liquid and medicinal liquid pump into the ...

Embodiment 3

[0040] The preparation method of the modified comet fiber filter material of the present invention comprises the steps of spinning polyester fiber raw materials, the step of converging the polyester fiber filaments, the step of injecting the polyester fiber filament bundles into briquettes, and briquetting the polyester fiber filament bundles Cutting off to form the step of comet type fiber filter material also includes the following steps:

[0041] (1) Put the mechanically processed comet-type fiber filter material into the washing tank, and after stirring for 1-2 minutes, rinse the silicone oil on its surface with clear water, then remove and control the water for later use;

[0042] 2) Put 2% (volume percentage) of viscose oil, 1.5% (volume percentage) of silicone oil and the rest of the liquid medicine into a container and stir evenly; then close the autoclave outlet valve and open the autoclave inlet Valve, input the configured medicinal liquid and medicinal liquid pump i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com