A kind of activated carbon polyvinyl alcohol ball and preparation method thereof

A technology of polyvinyl alcohol balls and polyvinyl alcohol, applied in chemical instruments and methods, fixed on or in inorganic carriers, fixed on/in organic carriers, etc., can solve the problem of easy bonding and knotting between fibers Large specific surface area of block and activated carbon, affecting mass transfer efficiency, etc., to achieve the effect of easy attachment and growth, good removal effect, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 85g of water, add 5g of polyvinyl alcohol, 9.4g of activated carbon, 0.5g of sodium alginate and 0.1g of sodium bicarbonate to the water in turn; stir and heat up to 95°C, dissolve for 0.5 hours until completely dissolved and mixed; The bubbles generated during the dissolution process are removed; the mixture obtained above is placed in the calcium chloride solution with a dropping pill machine, and the sodium alginate in the mixture reacts with calcium chloride to form a sphere; the sphere formed above is put into the aldehyde Pore making and solidification are carried out in the chemical solution, the sodium bicarbonate is completely reacted, then neutralized in the alkaline solution, and then washed with water to obtain the active carbon polyvinyl alcohol spherical carrier.

Embodiment 2

[0032] Take 65g of water, add 16g of polyvinyl alcohol, 12g of activated carbon, 5g of sodium alginate and 2g of calcium carbonate to the water in sequence; stir and raise the temperature to 98°C, dissolve for 1.5 hours until completely dissolved and mixed; after defoaming for 1 hour, the Bubbles are generated and removed; the mixture obtained above is placed in a calcium chloride solution with a dropping pill machine, and the sodium alginate in the mixture reacts with calcium chloride to form spheres; the spheres formed above are put into the formaldehyde solution for Pores are made and solidified, calcium carbonate is completely reacted, then neutralized in alkaline solution, and then washed with water to obtain activated carbon polyvinyl alcohol spherical carrier.

Embodiment 3

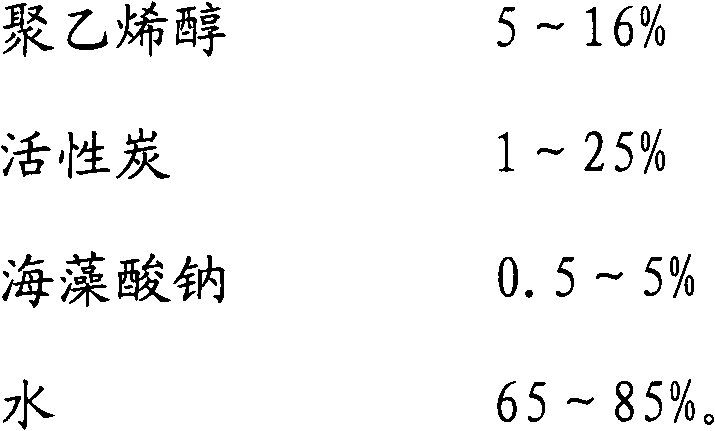

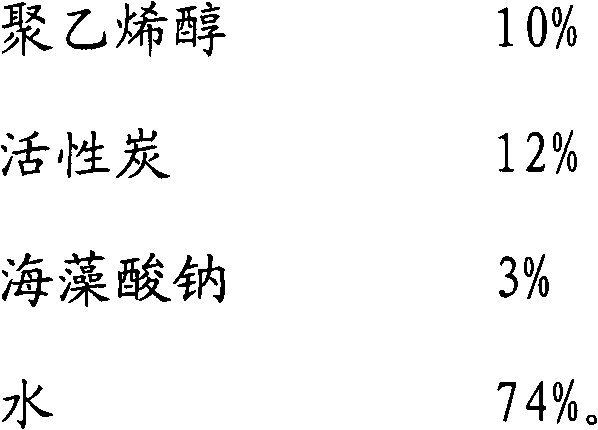

[0034] Take 74g of water, add 10g of polyvinyl alcohol, 12g of activated carbon, 3g of sodium alginate, and 1g of sodium bicarbonate to the water in sequence; stir and heat up to 90°C, dissolve for 1 hour until completely dissolved and mixed; after defoaming for 1 hour, it will be dissolved during stirring and dissolving The generated air bubbles are removed; the mixture obtained above is placed in a calcium chloride solution with a dropping pill machine, and the sodium alginate in the mixture reacts with calcium chloride to form a sphere; the sphere formed above is put into the formaldehyde solution Carry out pore making and solidification, sodium bicarbonate is completely reacted, then neutralized in alkaline solution, and then washed with water to obtain activated carbon polyvinyl alcohol spherical carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com