Brine stemming

A technology of gun mud and salt water, which is applied in the direction of blasting, etc., can solve the problems of water leakage, poor sealing of the bag opening, and difficulty in feeding, etc., and achieve the effects of reducing the probability of ignition, good flame extinguishing effect, and avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

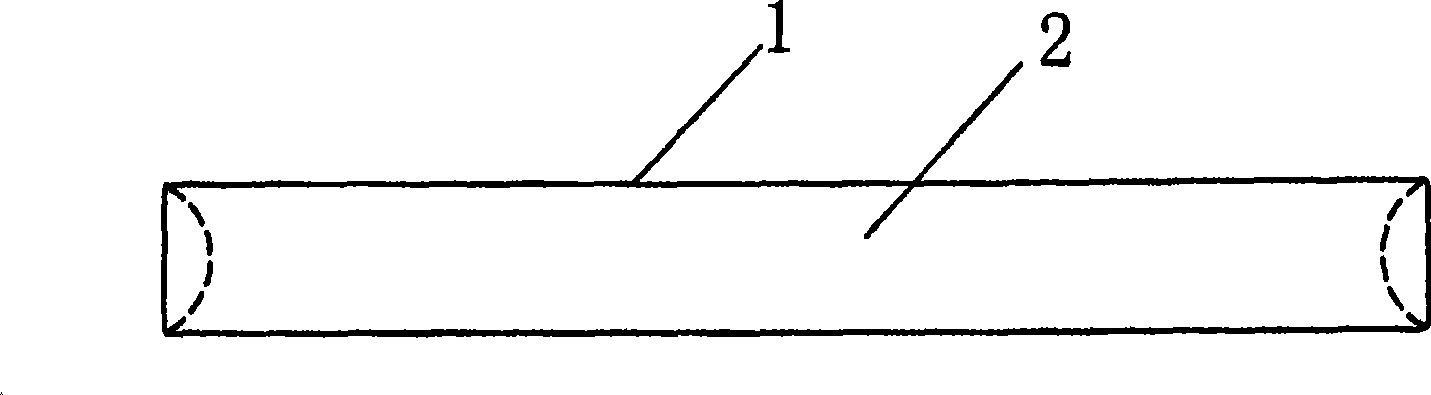

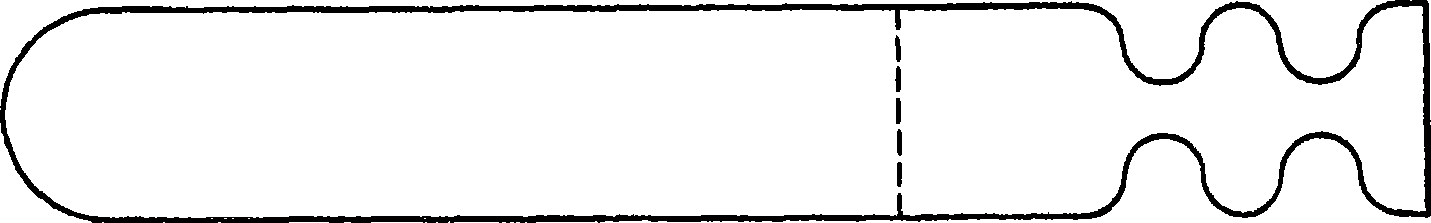

[0011] The shell 1 is a cylindrical plastic tube, and the brine 2 injected into the tube is an alkali metal salt solution. The alkali metal solution is made by mixing fresh water and alkali metal salt. Metal salts are NaCl, KCl, BaCl 2 , CaCO 3 、K 2 CO 3 、Na 2 SO 4 , Experiments have proved that these alkali metal salts can increase the gas ignition temperature from 670°C to 800°C, and inhibit the combustion and explosion of gas. The optimal concentration of alkali metal salts when mixed with fresh water is 30% to 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com