Coal seam mining-induced fracture field gas pressure measuring structure

A gas pressure and fracture field technology, applied in the field of gas pressure measurement structure in coal seam mining fracture field, can solve the problems of gas overflow and inaccurate measurement information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

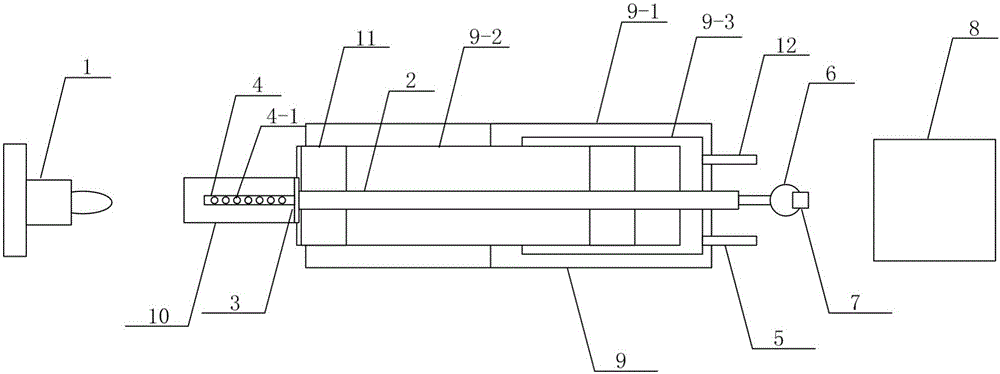

[0077] Please refer to the attached figure 1 :

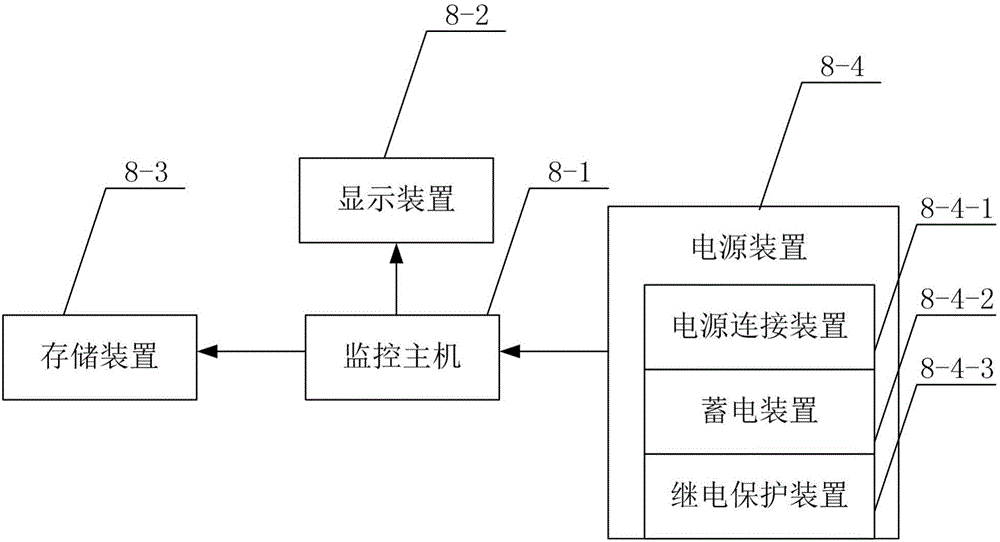

[0078] The present invention provides a gas pressure measurement structure for a coal seam mining fissure field. The gas pressure measurement structure for a coal seam mining fissure field includes a drilling rig 1, a gas pipe 2, a slurry stop belt 3, a gas collecting pipe 4, a grouting pipe 5, and a gas pressure gauge 6. The pressure sensor system 7 and the remote monitoring terminal 8, the drilling rig 1 drills a drill hole that goes deep into the coal seam from the rock wall to form a rock wall borehole 9 and a coal drill hole 10, and the rock wall borehole 9 includes an outer rock drill The hole 9-1 and the inner rock borehole 9-2, the outer rock borehole 9-1 is provided with an orifice pipe 9-3, the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com