Real-time detection apparatus for coal powder concentration and phase distribution in pneumatic conveying pipe

A technology of pneumatic conveying pipeline and real-time detection, which is applied in measurement devices, particle size analysis, analysis materials, etc., can solve the problems of high cost of linear radioactive sources, large space for measurement equipment, limitation of measurement devices, etc., and reduces the requirements for gamma ray protection. , The radiation protection range is small, and the effect of preventing pipeline wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

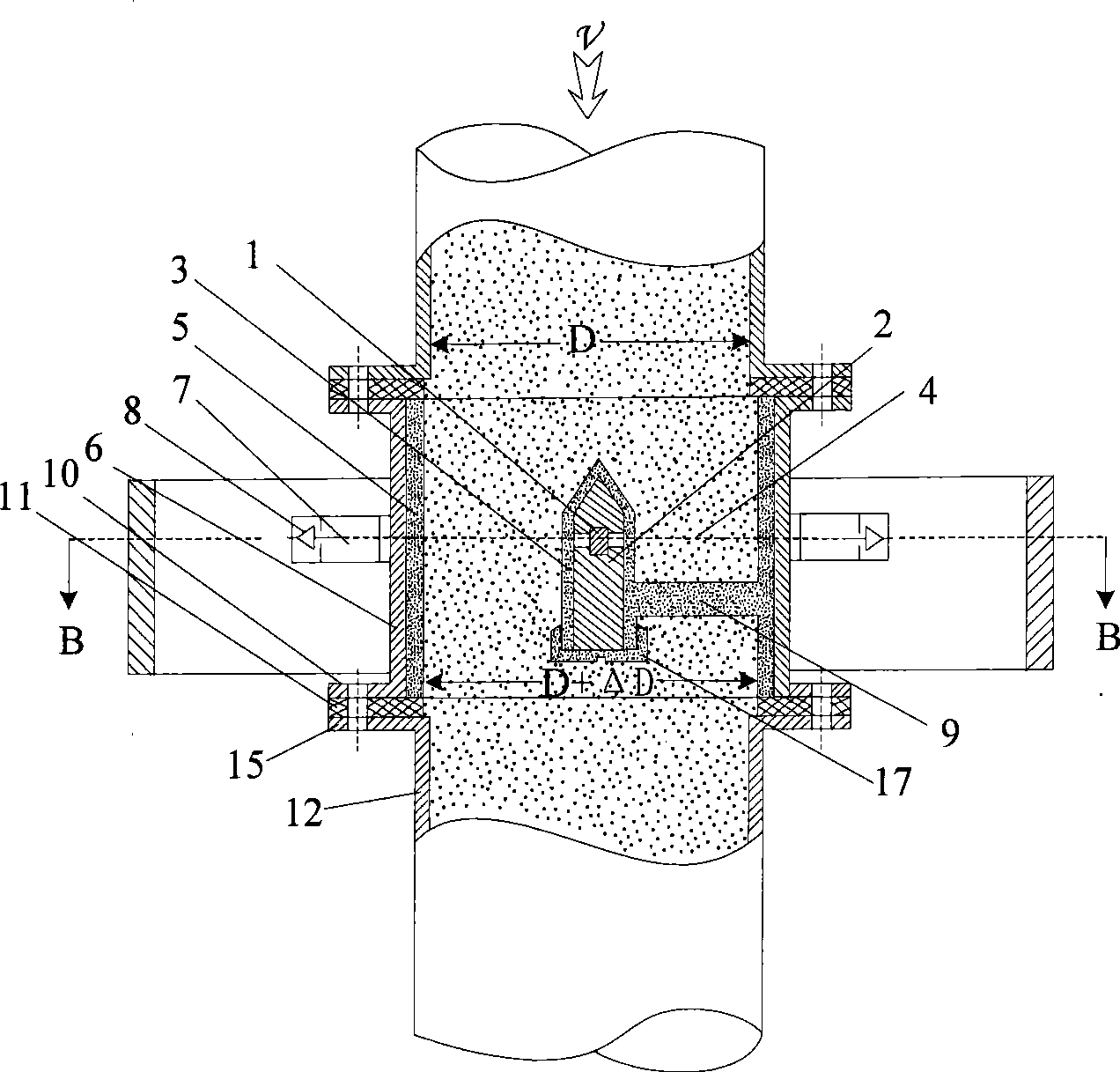

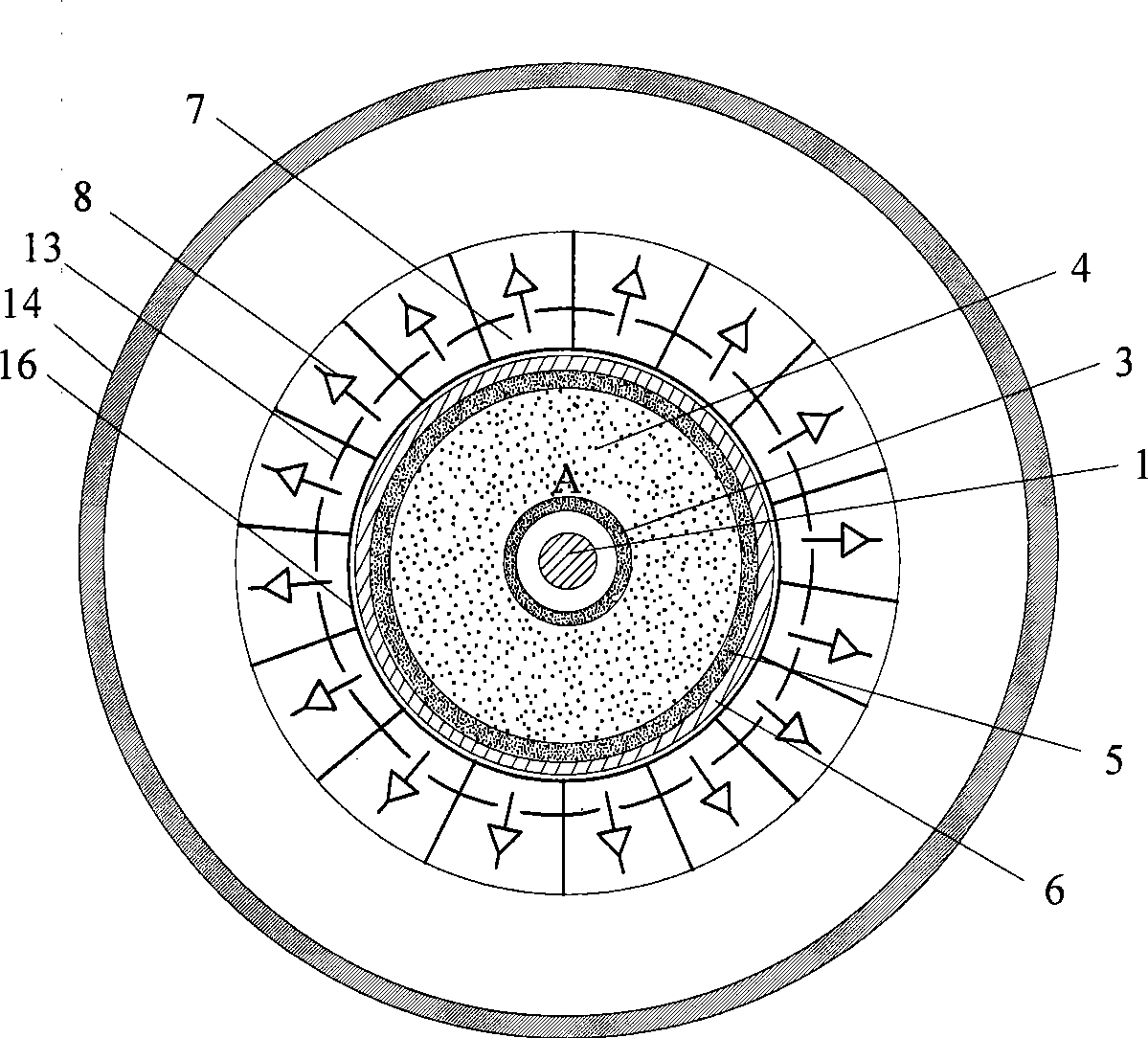

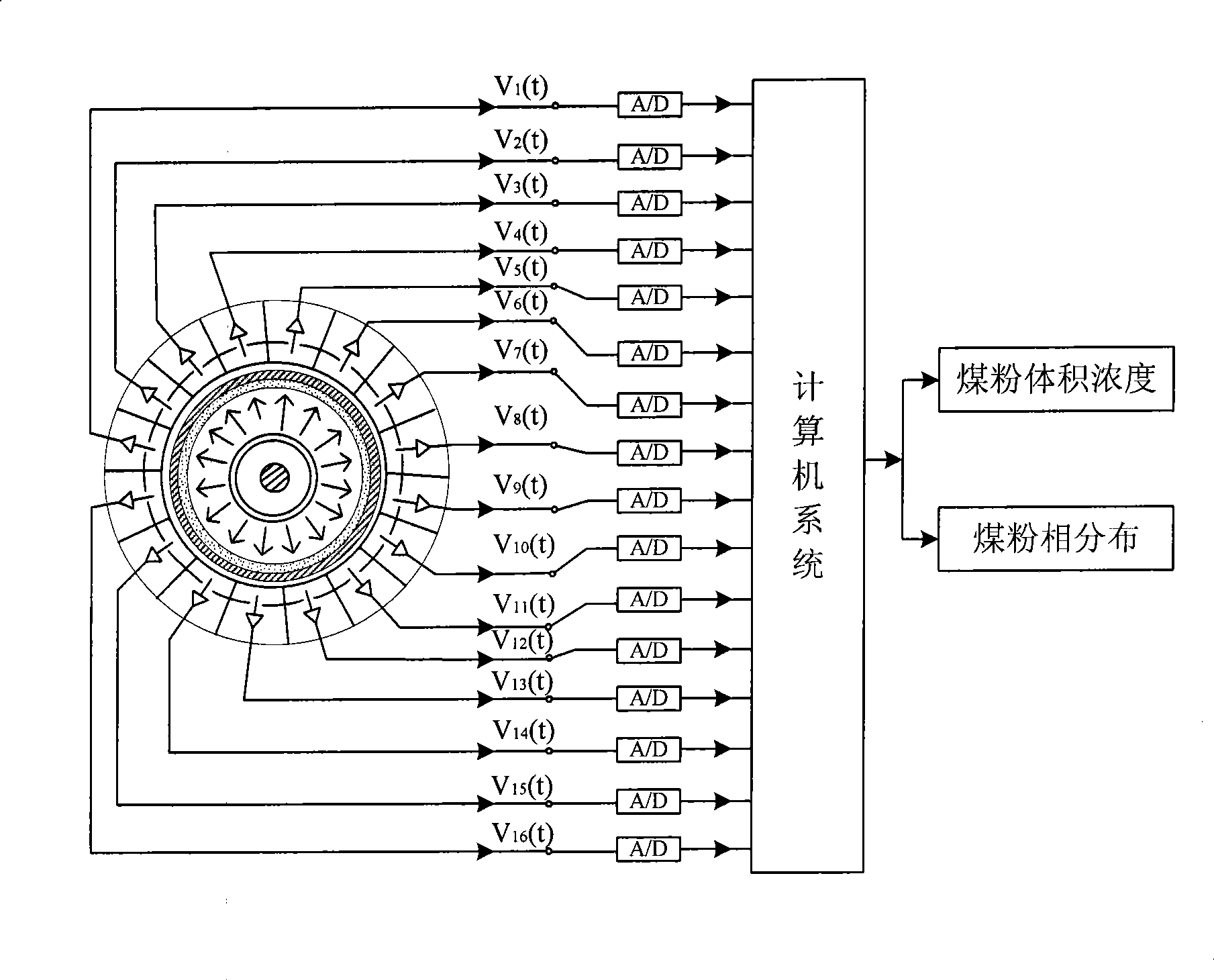

[0015] The invention provides a real-time detection device for the volume concentration and phase distribution of discrete phases of gas-solid two-phase flow in a pneumatic conveying pipeline. Describe below in conjunction with accompanying drawing and embodiment. figure 1 In, sensor Al 2 o 3 The ceramic lining 5 and the kovar alloy shell 6 are combined to form a sensor composite pipe section, and the sensor composite pipe section is connected to the connecting flange 15 of the measured pipeline 12 through the flange 10 and the sealing gasket 11 to realize the connection between the sensor composite pipe section and the measured pipeline. The point gamma source 1 of the sensor is arranged on the axis of the composite pipe section of the sensor, and the collimator 2 of the gamma source adopts a 360° plane exit angle, and the exit plane of the gamma rays emitted by the point gamma source 1 is perpendicular to the axis of the composite pipe section of the sensor , n independent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com