Micro-tip array device and its production method

A manufacturing method and micro-tip technology, applied in the manufacture of components, instruments, and nanostructures of instruments, can solve the problem of low working efficiency of single probes, achieve high-resolution nanoscale graphics processing and high-density data storage, Structural optimization, effect of reducing connection unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

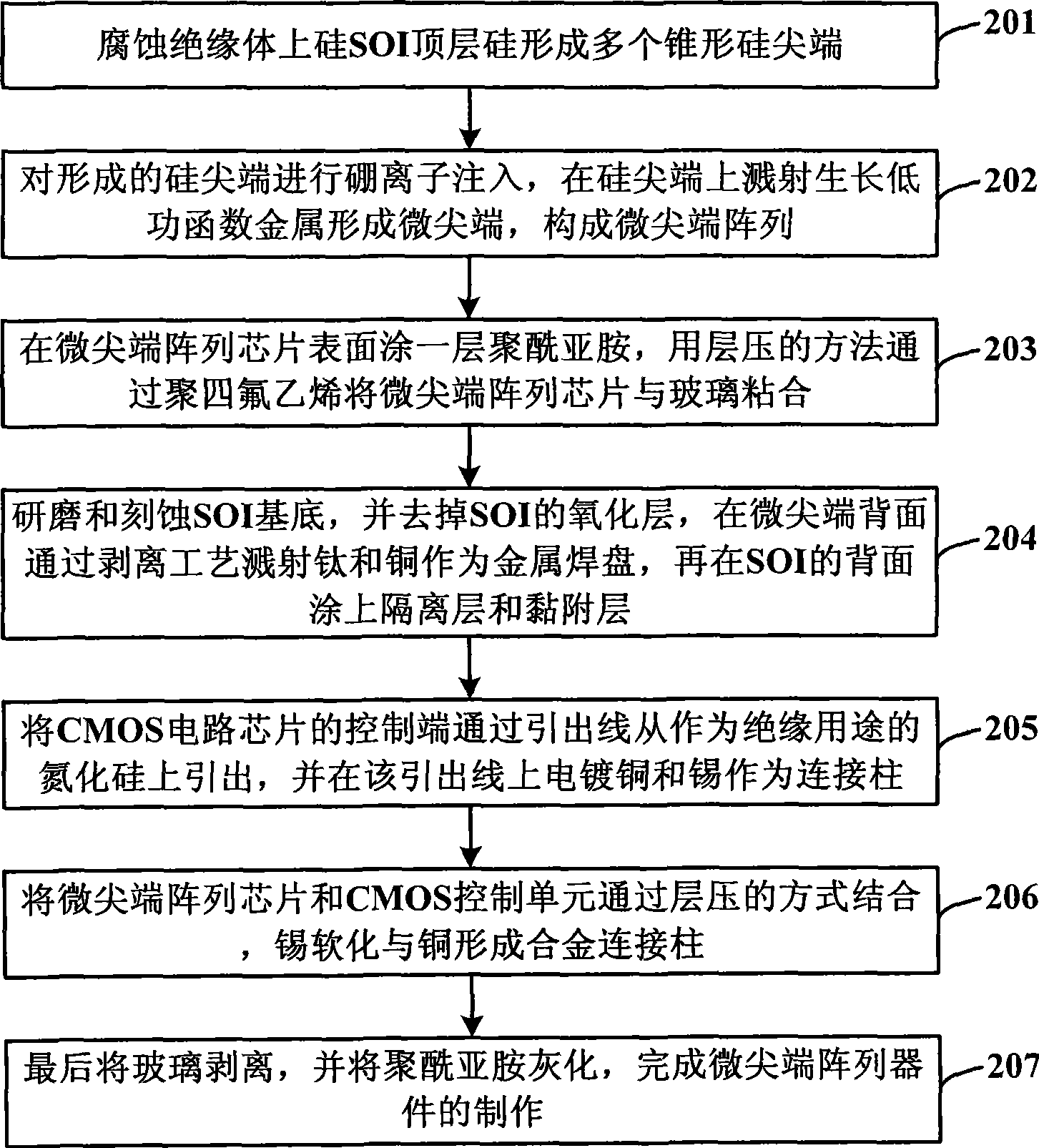

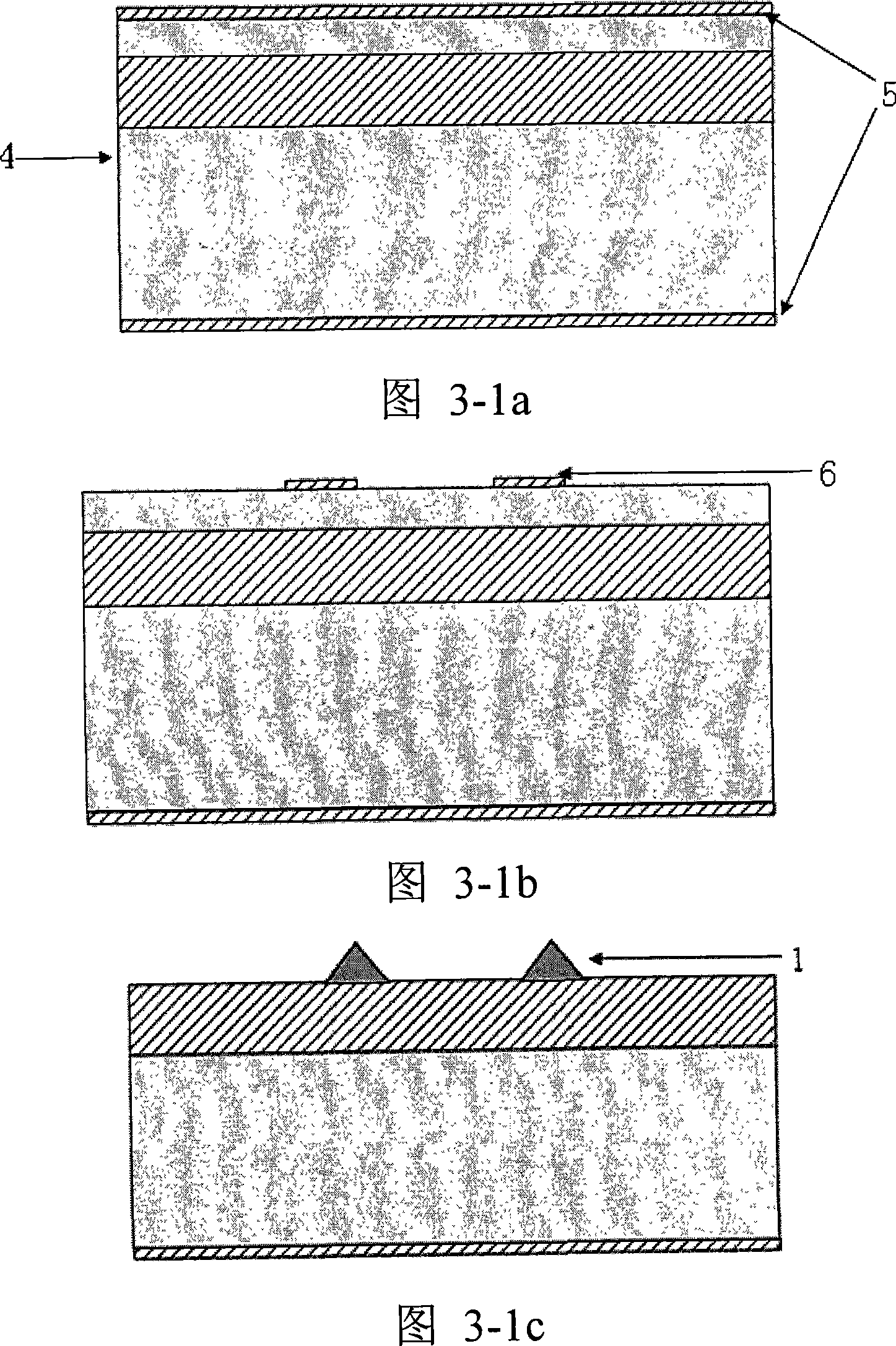

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0044] The micro-tip in the present invention utilizes the low-energy electron beam emitted by the metal tip under the field emission effect for graphic processing. Since the electron beam can effectively avoid the proximity effect, the resolution of the processed graphic can be improved and nano-scale graphics can be realized. Processing, and the processing speed can be improved by arraying the tip.

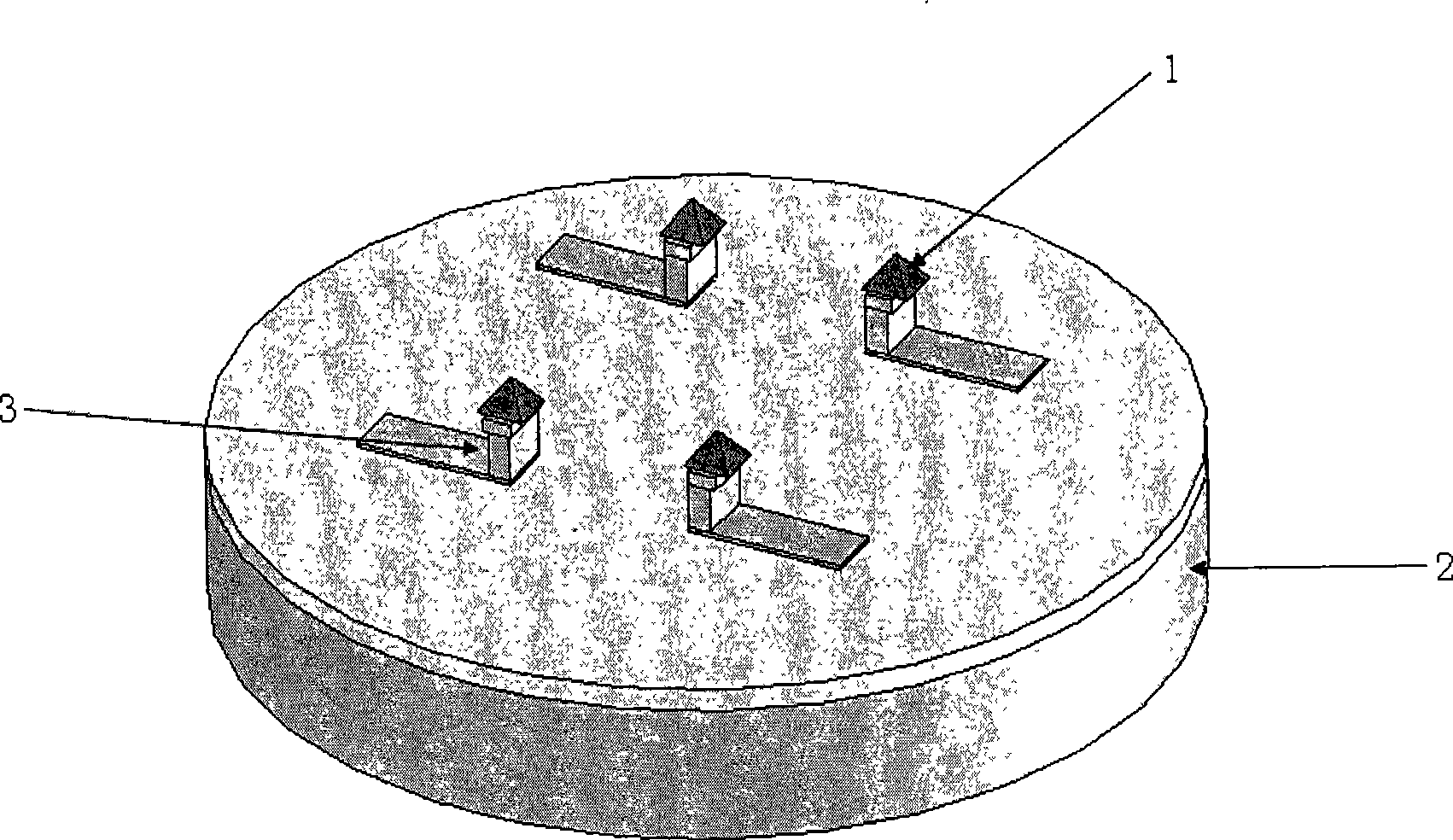

[0045] The invention proposes to use the connection column to realize the mechanical and electrical connection between the CMOS control circuit unit and the micro-tip array chip, effectively reduces the area of the connection line by utilizing the space, and improves the integration degree of the device.

[0046] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com