Wire break detecting device for wire electric discharge machine

A technology for detection of electric spark wires and broken wires, which is applied in the direction of measuring devices, electrode manufacturing, circuits, etc., can solve problems such as fluctuations and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

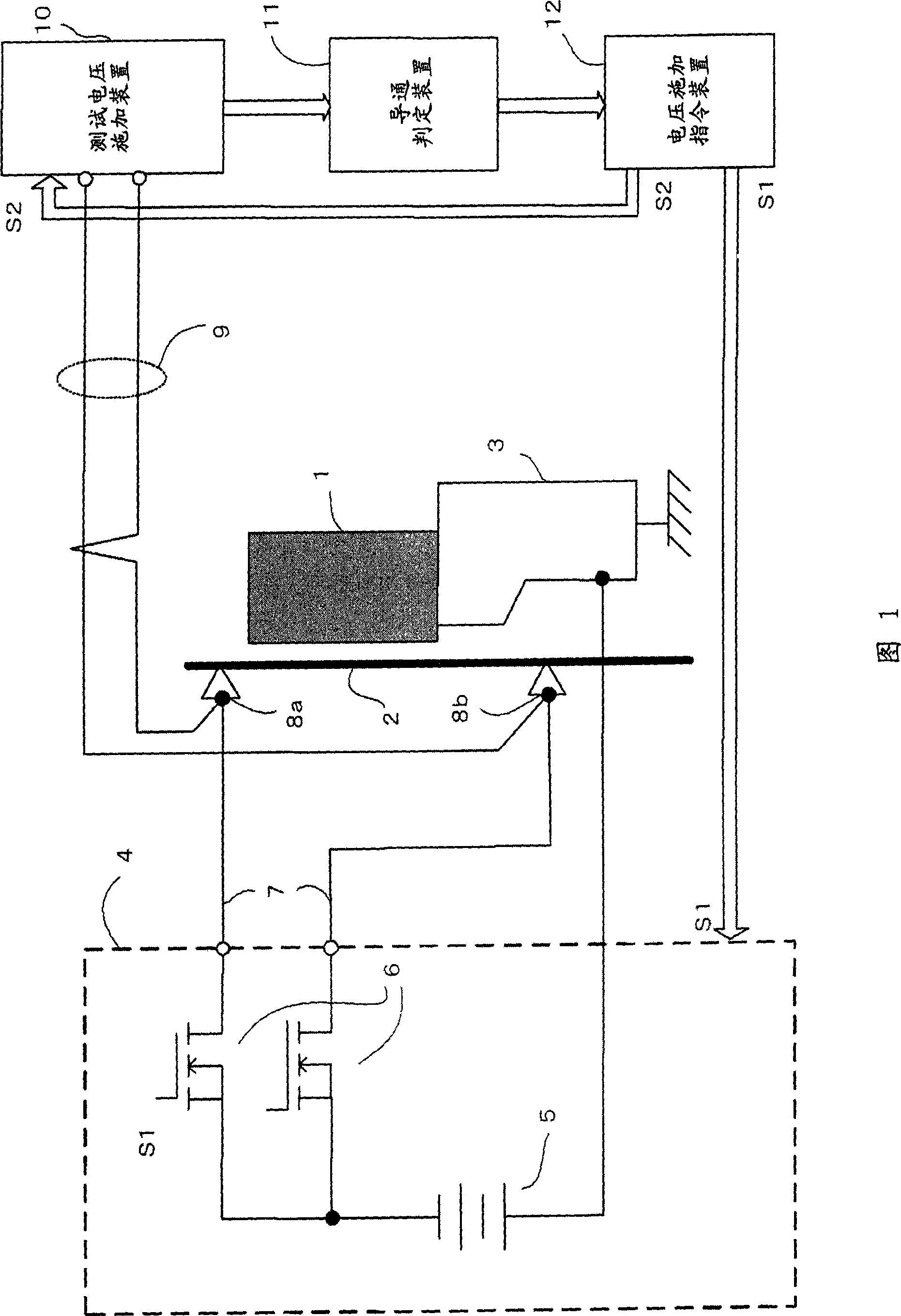

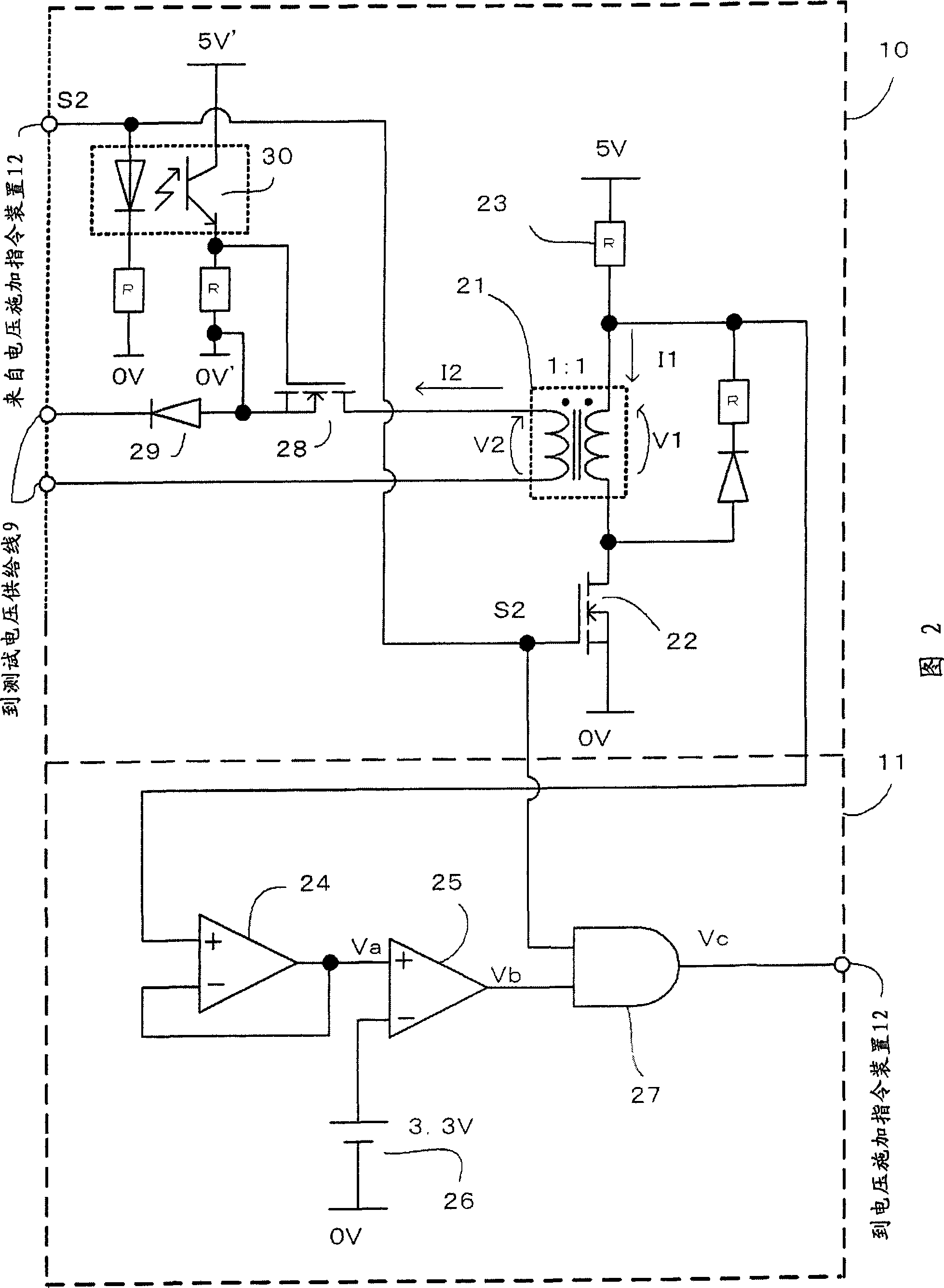

[0016] FIG. 1 is a schematic configuration diagram of an embodiment of a wire electrode disconnection detection device of the present invention.

[0017] The machining power source 4 includes a machining DC voltage source 5 and a switching element 6 for converting the DC voltage from the machining DC voltage source 5 to a pulse voltage and applying it to the wire electrode. In the machining DC voltage source 5 , one electrode is connected to the upper conductive mold 8 a and the lower conductive mold 8 b via the switching element 6 and the power supply line 7 , and the other electrode is connected to the workpiece placement table 6 .

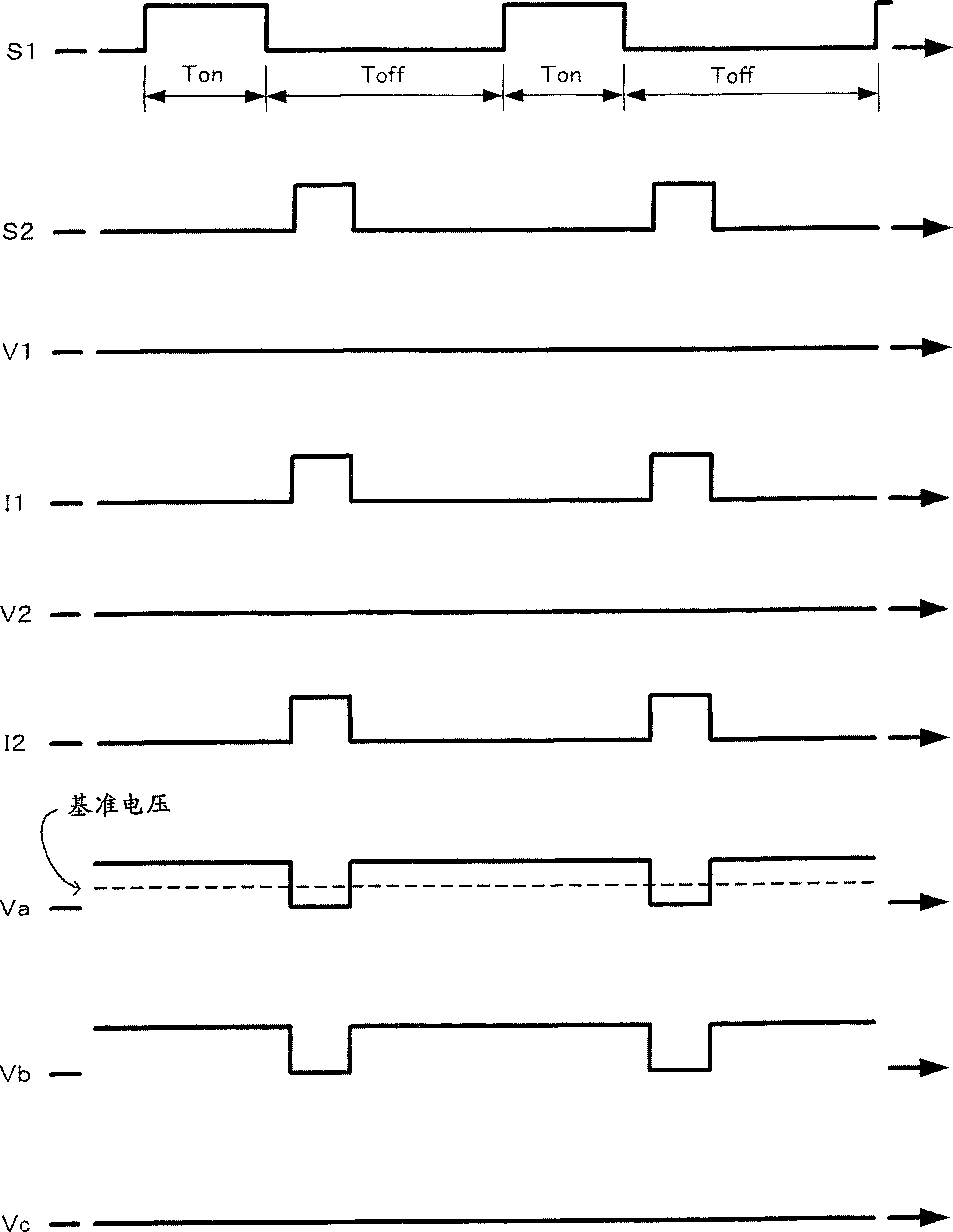

[0018] In the switching element 6 , an application command signal S1 is input from the voltage application command device 12 . The switching element 6 converts the DC voltage from the machining DC voltage source 5 in accordance with the application command signal S1 into a cycle of the voltage application time and the rest time during electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com