Method for synthesizing TS-1 molecular sieve

A technology of TS-1 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low oxidation activity and high content of non-skeletal titanium, achieve low dosage, overcome activity decline, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

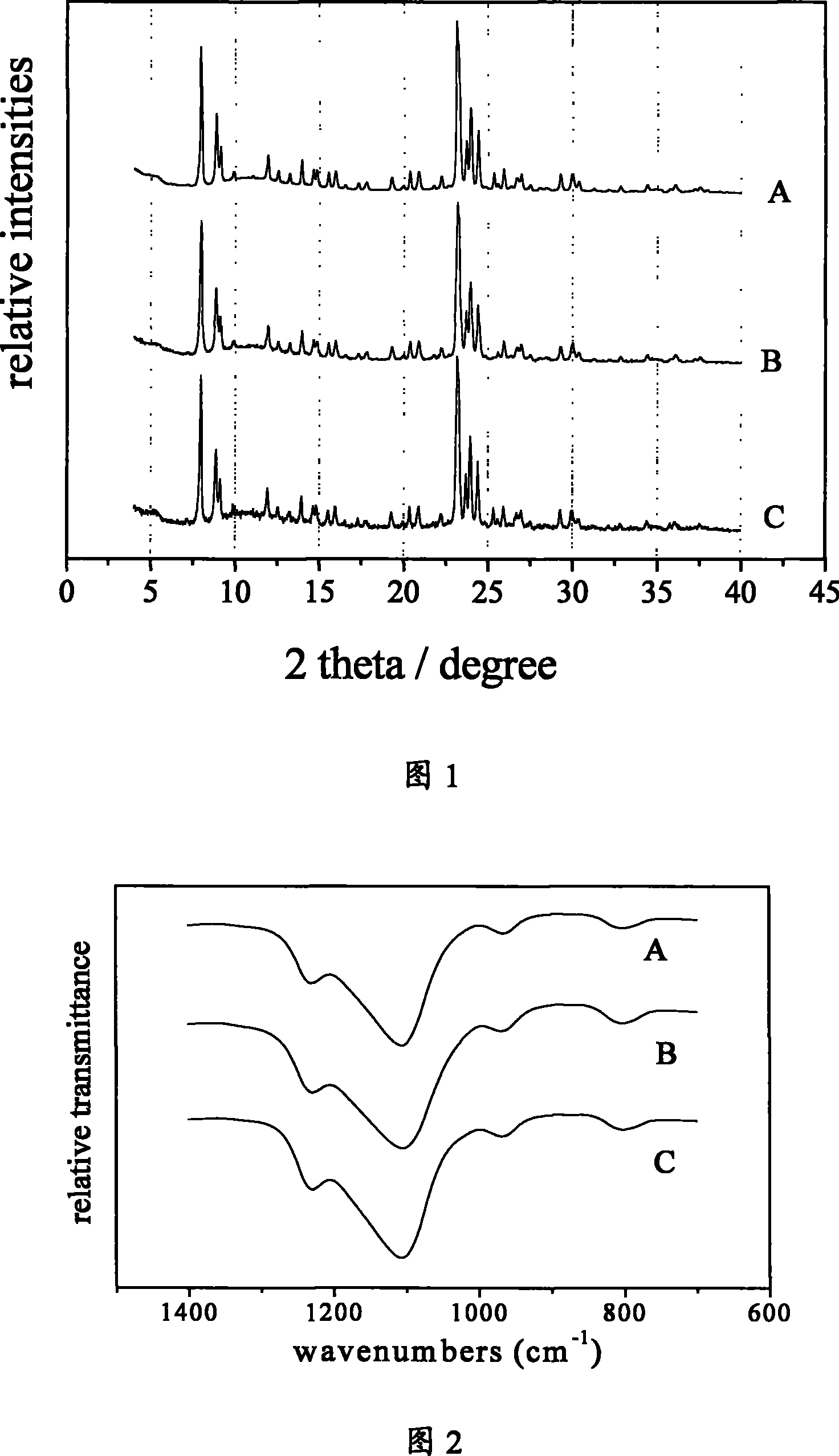

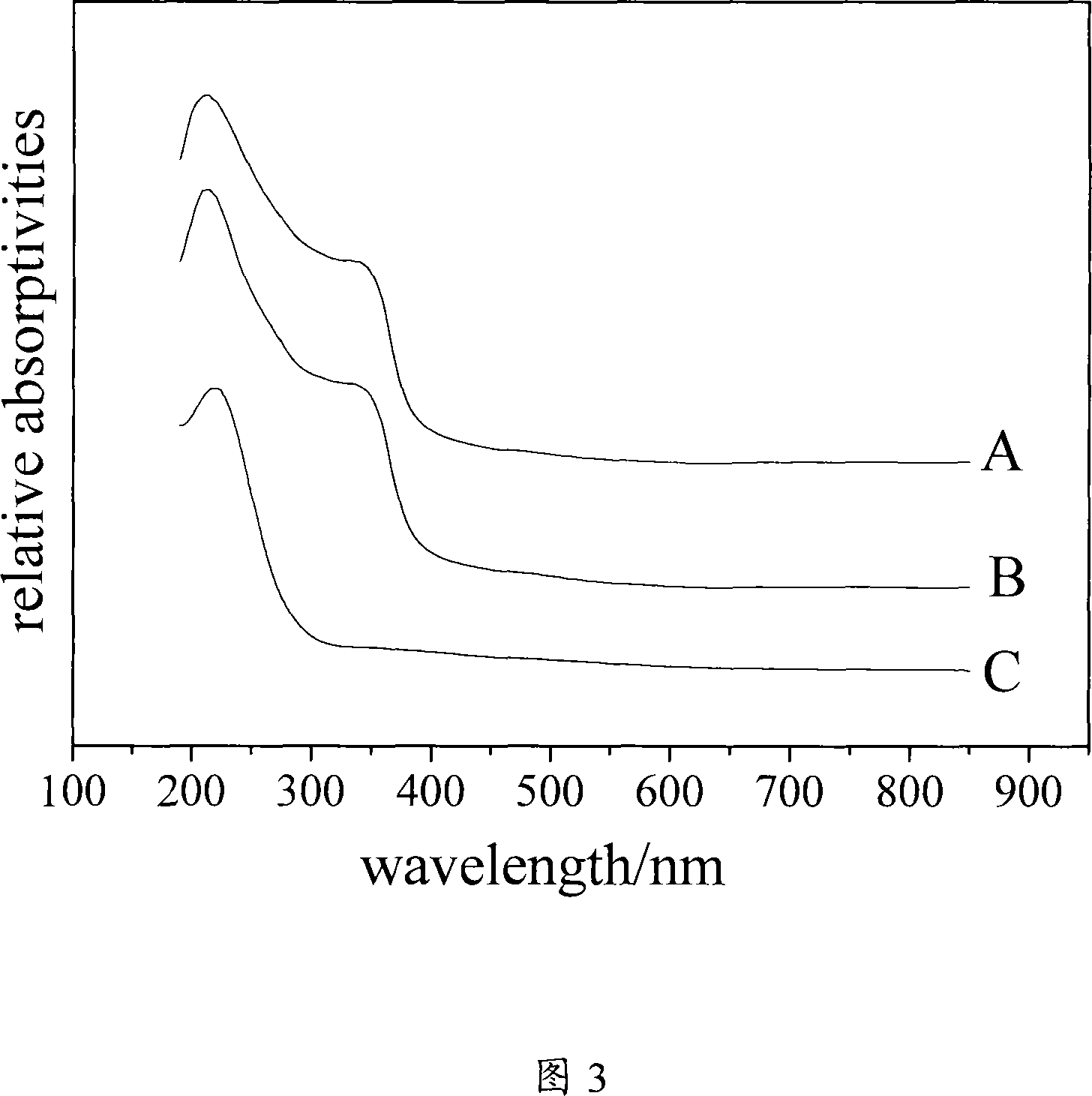

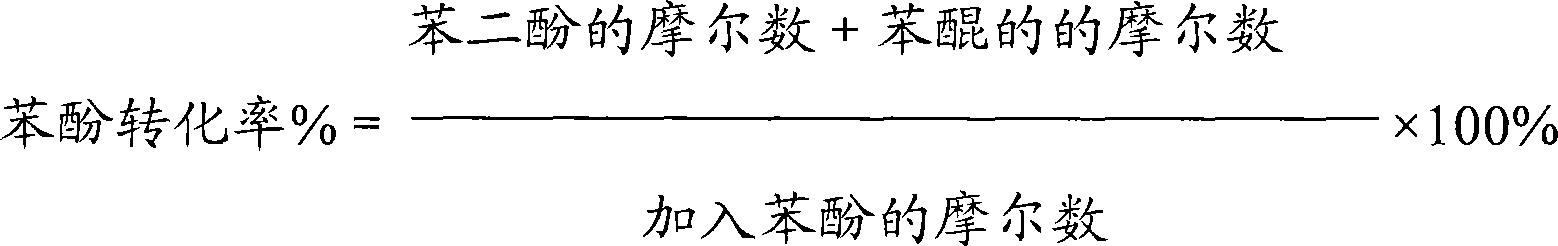

[0035] Mix tetraethyl orthosilicate, 10-20 mesh silica gel particles and tetrabutyl titanate evenly, then add it to the aqueous solution of tetrapropyl ammonium hydroxide and stir well, wherein tetraethyl orthosilicate (as SiO 2 In terms of), silica gel particles (in terms of SiO 2 In terms of), tetrabutyl titanate (as TiO 2 The molar ratio of tetrapropylammonium hydroxide and water is 1:1:0.04:0.1:15, and then transferred to a stainless steel sealed reaction kettle for crystallization at a temperature of 170°C and autogenous pressure for 24 hours, and the obtained crystal The compounded product was filtered, washed with water, dried at 110°C for 120 minutes, and then calcined at 550°C for 3 hours to obtain TS-1 molecular sieve. The particle size of the sample was 10-40 mesh as measured by sieving. Its XRD crystal phase diagram is shown in Figure 1 (C), similar to the comparative example, with MFI topology; the Fourier transform infrared spectrum is shown in Figure 2 (C), sim...

Embodiment 2

[0037] Mix tetraethyl orthosilicate, 20-40 mesh silica gel particles and tetraethyl titanate evenly, then add it to the aqueous solution of tetrapropyl ammonium hydroxide and stir well, wherein tetraethyl orthosilicate (use SiO 2 In terms of), silica gel particles (in terms of SiO 2 In terms of), tetraethyl titanate (as TiO 2 The molar ratio of tetrapropylammonium hydroxide and water is 1:0.5:0.1:0.25:75, and then transferred to a stainless steel sealed reaction kettle for crystallization at a temperature of 150°C and autogenous pressure for 96 hours, and the obtained crystal The product was filtered, washed with water, dried at 110°C for 120 minutes, and then calcined at 550°C for 3 hours to obtain TS-1 molecular sieve. The particle size of the sample was 40-80 mesh as measured by sieving. Its XRD crystal phase diagram, Fourier transform infrared spectrogram and ultraviolet-visible spectrogram are similar to the sample of Example 1. X-ray diffraction (XRD) and infrared spec...

Embodiment 3

[0039] Mix the silica sol, 40-80 mesh silica gel particles and tetrabutyl titanate evenly, then add them to the aqueous solution of tetrapropyl ammonium hydroxide and triethanolamine and stir well, wherein the silica sol (use SiO 2 In terms of), silica gel particles (in terms of SiO 2 In terms of), tetrabutyl titanate (as TiO 2 The molar ratio of tetrapropylammonium hydroxide, triethanolamine and water is 1: 2: 0.01: 0.15: 0.15: 35, and then transferred to a stainless steel sealed reaction kettle for crystallization at a temperature of 170°C and autogenous pressure for 48 After 1 hour, the obtained crystallized product was filtered, washed with water, dried at 110°C for 120 minutes, and then roasted at 550°C for 3 hours to obtain the product. The particle size of the sample was 80-120 mesh as measured by sieving. Its XRD crystal phase diagram, Fourier transform infrared spectrogram and ultraviolet-visible spectrogram are similar to those of the sample in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com